Sugarcane peeling device

A technology for stripping leaves and sugarcane, applied in the field of agricultural machinery manufacturing, can solve the problem of stripping sugarcane leaves that cannot be cut root by root, and achieve the effect of clean leaf stripping, not easy to break, and uniform brushing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

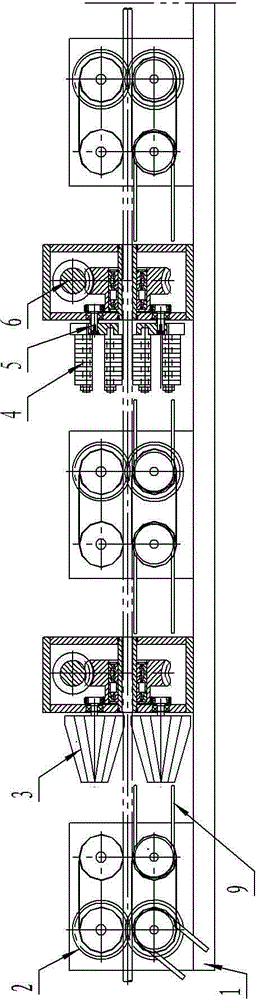

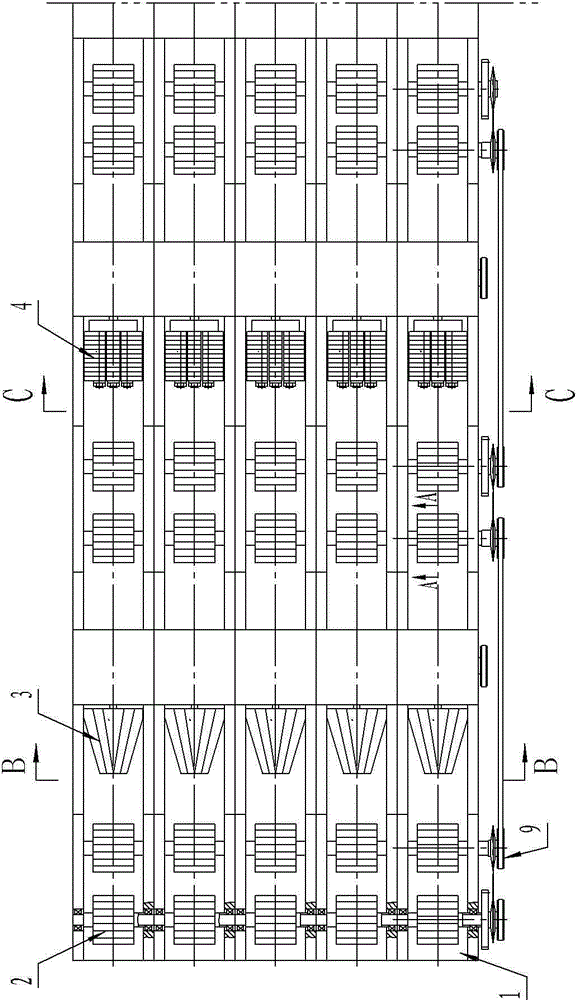

[0024] Figure 1 to Figure 5 The shown sugarcane leaf peeling device includes a base 1 and five cane stalk conveying channels installed on the base 1, and each cane stalk transporting channel is provided with two pairs of conveying channels facing opposite sides of the cane stalk transporting channel respectively. The driving conveying wheel unit that wheel 2 forms, a stripping leaf unit, another driving conveying wheel unit, yet another stripping leaf unit, the third driving conveying wheel unit or the like, so driving conveying wheel unit and stripping leaf unit are arranged at intervals. Cane stalk conveying passage is driven by motor and belt transmission mechanism 9.

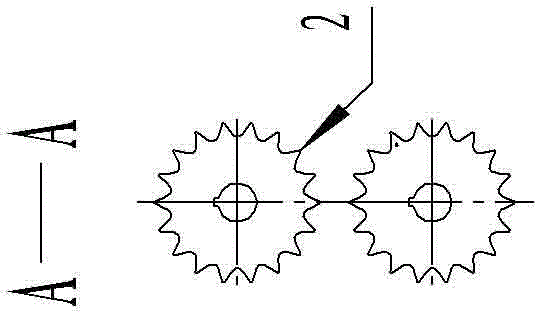

[0025] The conveying wheel 2 in the driving conveying wheel unit is a rubber wheel, and the two ends of the conveying wheel 2 are installed on the support plate of the base 1 through bearings, and the front pair of conveying wheels 2 and the rear pair of conveying wheels 2 of the driving conveying wheel uni...

Embodiment 2

[0028] Image 6 In the shown sugarcane leaf stripping device, the rotating shafts 5 of the two stripping elements of each leaf stripping unit on the cane stalk conveying channel are connected and driven by a pair of worm gears 6 and distributed obliquely at the lower left and upper right of the cane stalk conveying channel , forming an inclined leaf stripping unit. The leaf stripping element of each leaf stripping unit is the tooth 3 of the conical rubber gear mounted on the rotating shaft 5 . Other structures are as in Embodiment 1.

Embodiment 3

[0030] Figure 7 In the shown sugarcane leaf stripping device, the rotating shafts 5 of the two stripping elements of each leaf stripping unit on the cane stalk conveying channel are connected and driven by a pair of worm gears 6 and distributed obliquely at the lower left and upper right of the cane stalk conveying channel , the leaf stripping element of each leaf stripping unit is contained on the rotating shaft 55 and is distributed on the same circumference three groups of rubber brushes, and the rubber brushes include the brushes 4 arranged axially and eccentrically.

[0031] In other embodiments, the number of leaf stripping units on the cane stalk conveying channel can be adjusted and changed according to needs, and the leaf stripping units can also be adjusted according to needs. The gear stripping unit is interactively selected for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com