Sugarcane Leaf Stripping Device

A technology for peeling leaves and sugar cane, which is applied in the field of agricultural machinery manufacturing, can solve the problems of peeling leaves one by one of the sugarcane that cannot be cut, and achieves the effects of sufficient leaf peeling, not easy to break and damage, and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

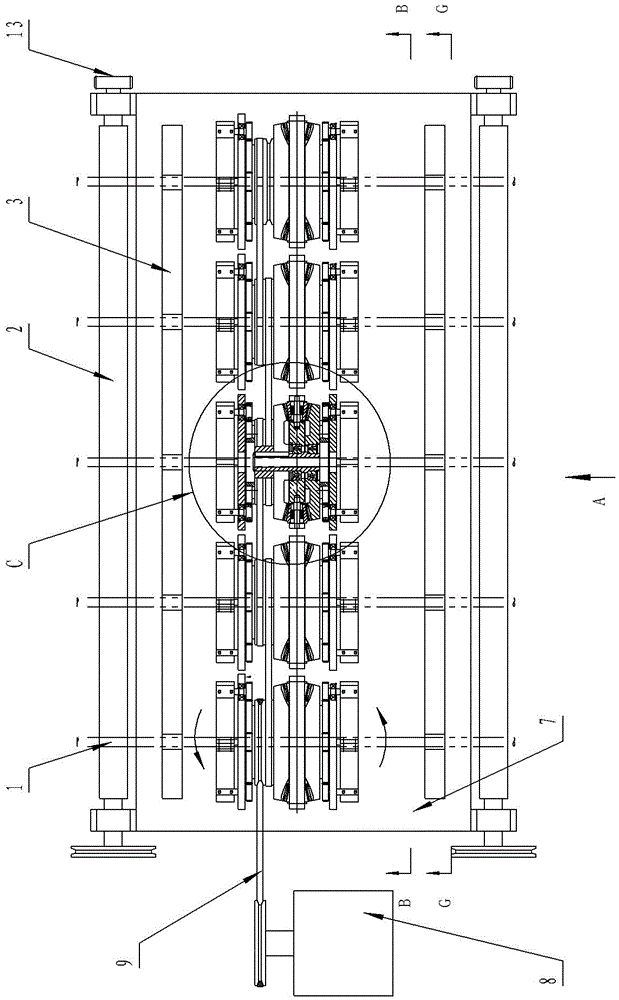

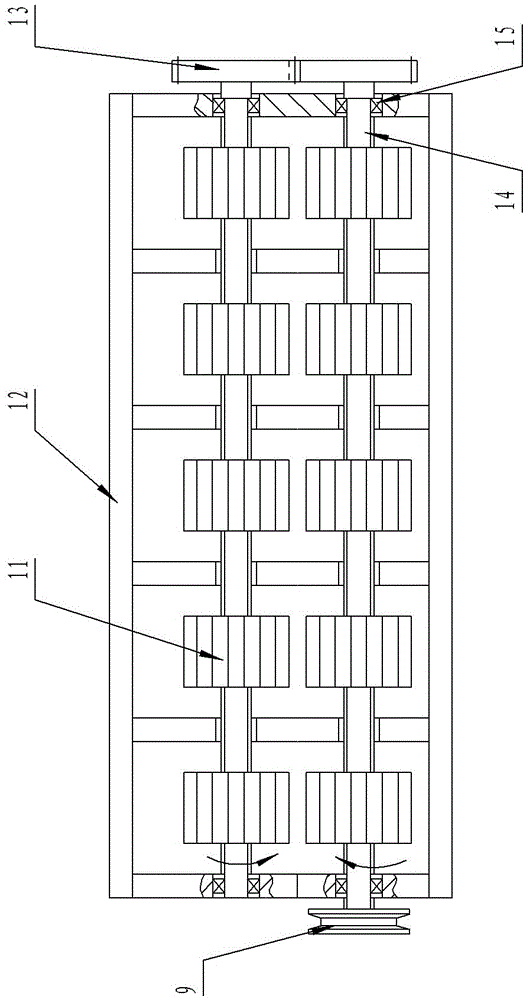

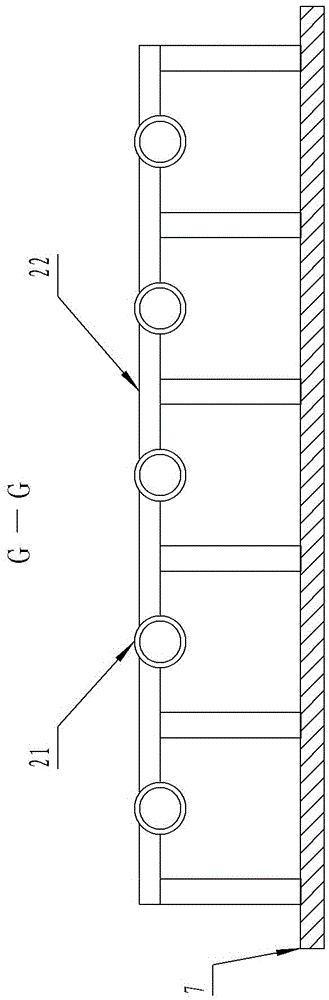

[0027] Figure 1 to Figure 5 In the shown embodiment one of the sugarcane leaf stripping device, five cane stalk conveying passages are installed on the base 7, and each cane stalk conveying passage is provided with a leaf stripping unit, and two conveying guide cylinders 21 and two pairs are respectively arranged on the cane stalks. Conveying rubber wheels 11 opposite to the two sides of the cane conveying channel; the leaf stripping unit includes two flexible leaf stripping assemblies with opposite rotation directions, and the rotating space of the two leaf stripping assemblies passes through the cane straw conveying channel, the The rotating shaft of the stripping assembly is arranged parallel to the cane stalk conveying channel; the cane stalk conveying channel is driven by the motor 8 and the belt transmission mechanism 9 .

[0028] Two frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com