Hidden synchronous spring lock unlocking method, key and lock cylinder

A technology of pin locks and lock cylinders, applied to cylinder pin locks, locks with turning keys, keys, etc., to achieve the effect of improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

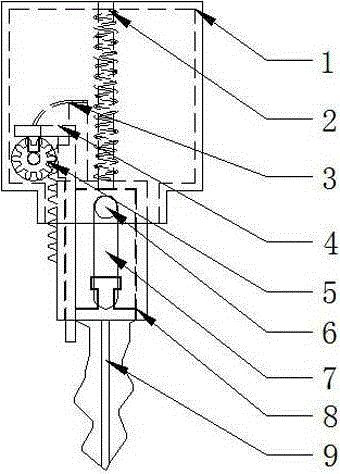

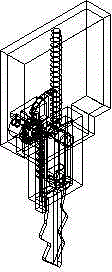

[0080] With reference to the accompanying drawings, the key of the present invention mainly includes a key handle and a corrugated part. The key handle includes a key handle shell 1, a return spring 2, a return spring sheet 3, a baffle locking member 4, a baffle locking gear 5, a cylindrical shaft 6, Baffle plate motion guide 7, baffle plate 8. The baffle locking gear 5 has two working surfaces, one is a gear surface, and the other is a cylindrical surface with a locking groove. The baffle locking gear 5 continues to rotate until the locking protrusion on the baffle locking part 4 is stuck in the locking groove on the baffle locking gear 5, and the baffle locking gear 5 passes through the shaft and the hole in the lower left corner of the key handle shell 1 Cooperate, the baffle locking gear 5 can rotate around this hole, the baffle 8 is sleeved on the baffle movement guide 7, wherein the cylindrical guide rod of the baffle movement guide 7 passes through the cylindrical hole ...

Embodiment 2

[0091] A method for unlocking a hidden synchronous tumbler lock. When a key is inserted into the keyhole to unlock the lock, the cover 13 arranged between the lock cylinder shell 10 and the lock cylinder rotor 14 is first moved into the lock cylinder rotor 14 and blocks the keyhole, and then the key The rotating lock cylinder rotor 14 is normally opened; like this, when the keyhole is opened, if the lock is unlocked abnormally, although the existence of the pin can be sensed, the specific position of the pin cannot be sensed because the lock core rotor 14 cannot effectively rotate, and when the lock core rotor 14 effectively rotates, then because the keyhole is blocked, can't sense the marble; that is, when unlocking with the key, the interior of the lock cylinder must be completely separated from the outside, so there is no possibility of technical unlocking; It is impossible to perceive the actual position of the pin by turning the pin, so it is impossible to technically unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com