Dynamic pull/pressing and torsion synchronous combined loading experiment device

A loading device and joint loading technology, applied in the direction of testing material strength by applying stable tension/pressure, testing material strength by applying stable torsion, etc., can solve problems such as difficulty in recording incident waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in conjunction with specific embodiments and accompanying drawings, but this is not intended to limit the protection scope of the present invention.

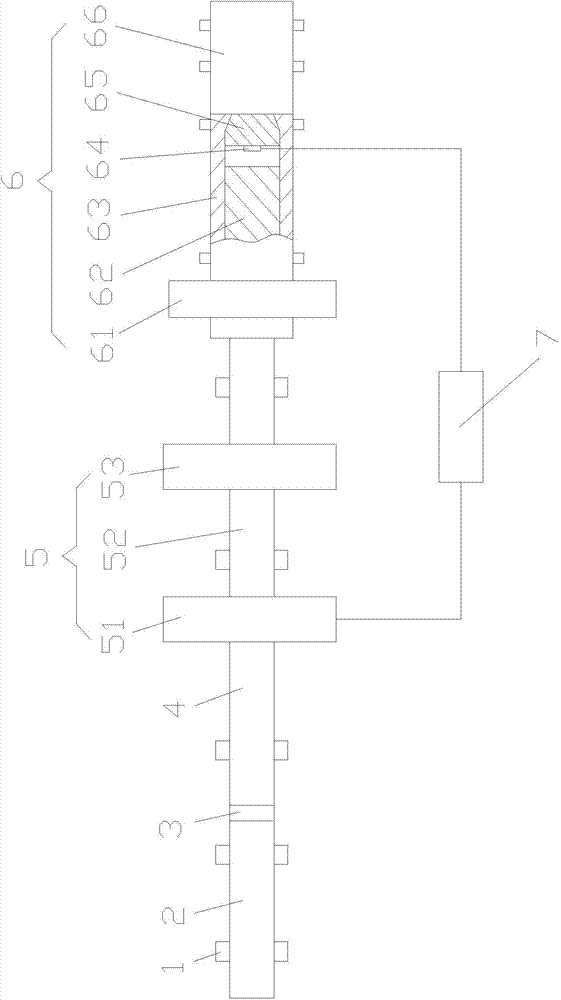

[0017] Such as figure 1 As shown, a dynamic tension and torsion synchronous joint loading experimental device includes a transmission rod 2 and an incident rod 4 arranged on a rolling support 1, a test piece 3 is installed between the transmission rod 2 and the incident rod 4, and the incident rod 4 is set There is a torsional wave loading device 5 and a tension wave loading device 6, the distance between the tension wave loading device 6 and the end of the incident rod 4 where the test piece 3 is installed is greater than the distance between the torsional wave loading device 5 and the end of the incident rod 4 where the test piece 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com