Flip type drain valve and drain valve control method

A control method and drainage valve technology, which is applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of waste of water resources and non-adjustable drainage, and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

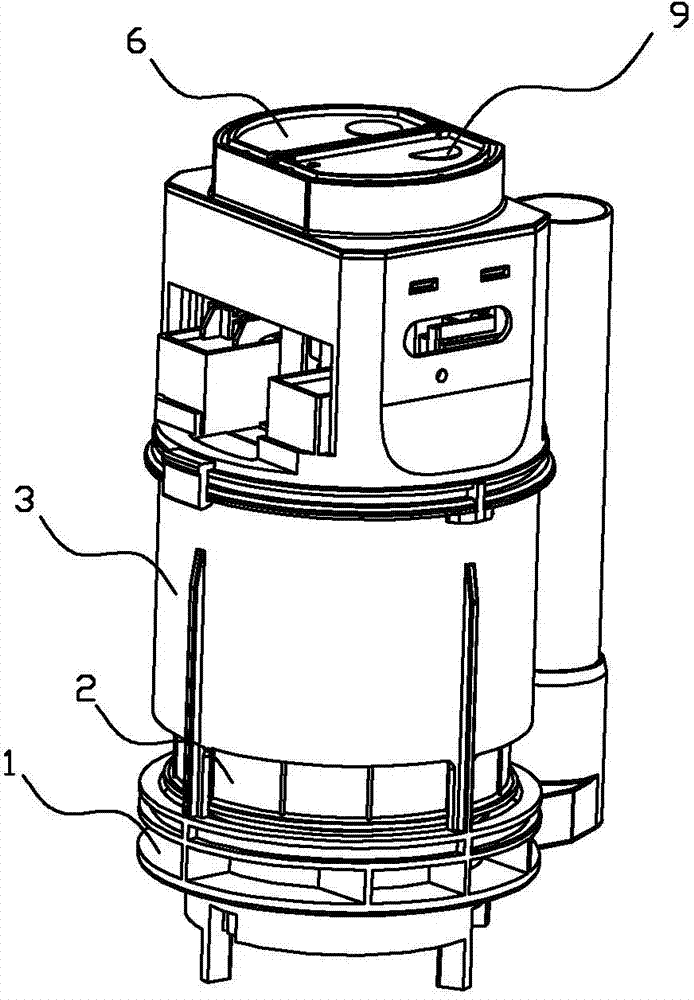

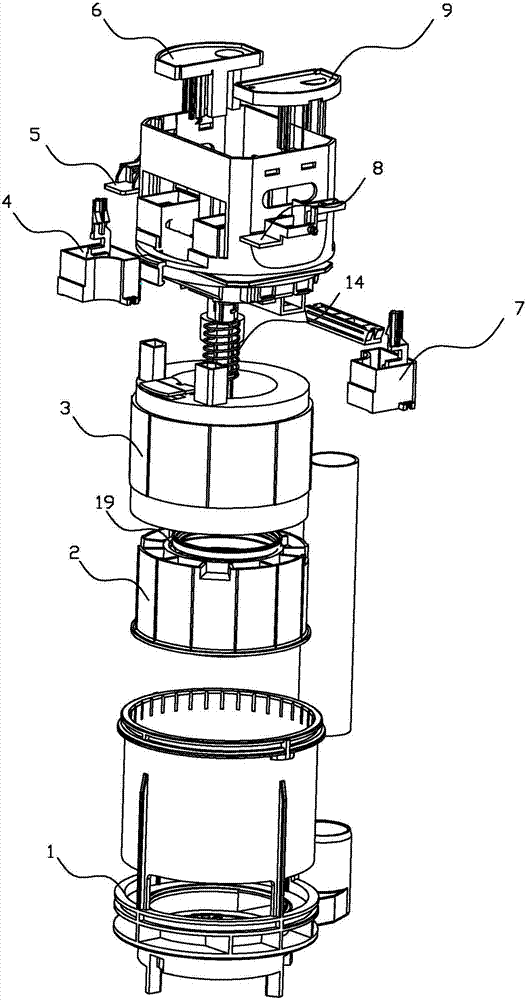

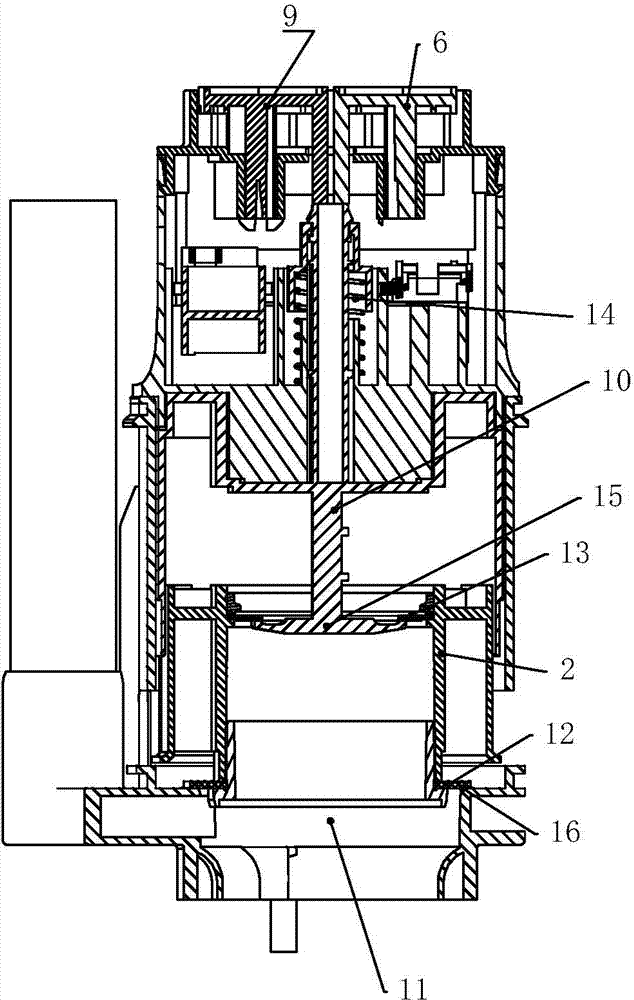

[0043] Such as figure 1 , figure 2 As shown, the drain valve includes a base 1, a water-stop buoy 2, an outer cover 3, a full row of buoys 4, a full row of ventilation valves 5, a full row of buttons 6, a full row of chambers 20, a half row of buoys 7, a half row of ventilation valves 8, A half row of buttons 9, a half row of chambers, a drain rod 10, a drain port 11, a drain seal 12, a water stop buoy seal 13, and a return spring 14.

[0044] This embodiment takes the full row function as an example. After pressing the button 6 of the whole row, the water in the cavity on the upper surface of the water-stop buoy 2 flows out first, and because the gap around the cavity is small, the amount of water supplied into the cavity is very small, so that the water pressure in the cavity decreases rapidly, and the water is stopped. The upward hydraulic pressure of the buoy 2 is greater than the sum of the self-weight of the water-stop buoy 2 and the downward hydraulic pressure, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com