An online visual detection device and method for cracks on the surface of poultry eggs

A surface crack and visual detection technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of high installation accuracy and high equipment cost, and achieve low equipment cost, full detection range and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0055] 1. Device

[0056] 1. Overall

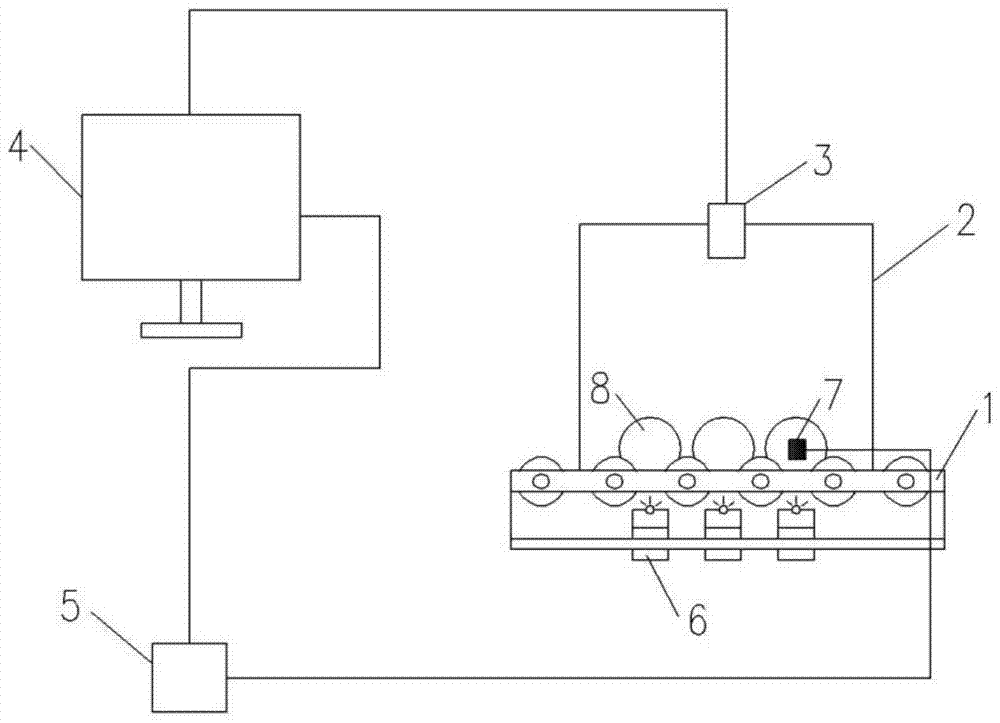

[0057] Such as figure 1 , the device is composed of a conveyor belt 1, a dark box 2, an industrial camera 3, a computer 4, a single-chip microcomputer 5, a light source 6 and a photoelectric switch 7;

[0058] Its location and connection relationship are:

[0059] A dark box 2 is arranged above the conveyor belt 1, and an industrial camera 3 is arranged in the middle of the top of the dark box 2; a light source 6 is arranged below the conveyor belt 1, and the light source 6 transmits poultry eggs placed on the conveyor belt 1 through the gap of the conveyor belt 1 8; The photoelectric switch 7 is arranged on the inner side of the dark box 2;

[0060] The photoelectric switch 7 is connected with the single-chip microcomputer 5 through the data line; the single-chip microcomputer 5 and the industrial camera 3 are respectively connected with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com