An automatic blackboard eraser mechanism for horizontal push-pull blackboard

An automatic blackboard eraser and push-pull technology, which is applied in the field of teaching equipment, can solve the problems of high cost, heavy blackboard workload, and occupation of classroom time, and achieve the effects of saving time, improving efficiency, and improving teaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

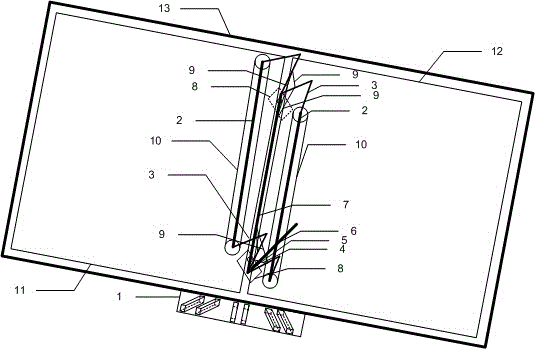

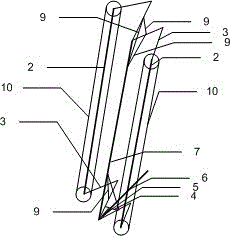

[0015] like figure 1 As shown, an automatic blackboard eraser mechanism for a horizontal push-pull blackboard, the blackboard eraser structure is vertically fixed at the junction of the two moving blackboards of the horizontal push-pull blackboard, when the teacher needs to erase the blackboard, for example, the left blackboard is full of , you need to erase all, you only need to remove the handle of the blackboard eraser from Figure 4 The groove in the middle of the fixing bar shown is lifted and turned to the left, and fixed in the groove on the left side of the fixing bar. At this time, the left blackboard eraser is in close contact with the left blackboard. Pull the left blackboard to the right to complete quick erasing. If you only erase a part, you only need to lift the handle and return it to the groove in the middle of the fixing bar at the place that does not need to be erased; when you need to erase all or part of the right blackboard, the operation is similar, in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com