Toner for electrostatic charge image development, two-component developer, and method for forming image

An electrostatic charge image and toner technology, which is applied in the direction of developer, electrography, instrument, etc., can solve the problems of increased electrostatic adhesion, easy over-charging, and reduced output image density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0209] (1) Coagulation and fusion process

[0210] Add 328 parts by mass of "resin microparticle dispersion [A1]" in terms of solid content and 2000 parts by mass of ion-exchanged water into a reaction vessel equipped with a stirring device, a temperature sensor, and a cooling pipe, and then add 5 mol / liter of hydrogen Aqueous sodium oxide solution, pH adjusted to 10 at 25°C.

[0211] Next, under stirring, an aqueous solution obtained by dissolving 60 parts by mass of magnesium chloride in 60 parts by mass of ion-exchanged water was added over 10 minutes at 30°C. Thereafter, after standing for 3 minutes, the temperature was raised, and the temperature of the system was raised to 80° C. over 60 minutes, and the particle growth reaction was continued at 80° C. In this state, the particle diameter of the associated particles was measured with "Coulter Multisizer 3" (manufactured by Beckman Coulter Co.), and the median diameter (D 50 ) reached 4.0 μm, poured 72 parts by mass of ...

Embodiment 2

[0220] (1) Coagulation and fusion process

[0221] Add 328 parts by mass of "resin microparticle dispersion [A1]" in terms of solid content and 2000 parts by mass of ion-exchanged water into a reaction vessel equipped with a stirring device, a temperature sensor, and a cooling pipe, and then add 5 mol / liter of hydrogen Aqueous sodium oxide solution, pH adjusted to 10 at 25 °C.

[0222] Next, under stirring, an aqueous solution obtained by dissolving 60 parts by mass of magnesium chloride in 60 parts by mass of ion-exchanged water was added over 10 minutes at 30°C. Thereafter, after standing for 3 minutes, the temperature was raised, and the temperature of the system was raised to 80° C. over 60 minutes, and the particle growth reaction was continued at 80° C. In this state, the particle diameter of the associated particles was measured with "Coulter Multisizer 3" (manufactured by Beckman Coulter Co.), and the median diameter (D 50 ) reached 6.0 μm, a solution obtained by dis...

Embodiment 3~12

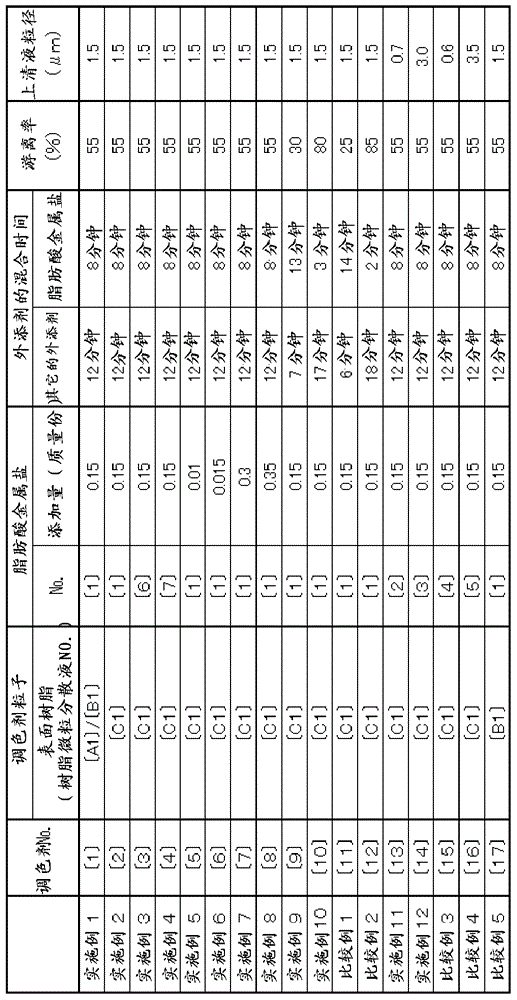

[0228]

[0229] In the production of toner [2], toners [3] to [16] were obtained in the same manner except that the formulation in Table 1 was followed. Table 1 shows the free ratio of the fatty acid metal salt of the obtained toner and the number average particle diameter of the particles present in the supernatant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap