A method for controlling the adhesive layer thickness of optical remote sensor space truss rods

A technology of optical remote sensors and space trusses, which is applied in the direction of material gluing, connecting components, and photographic devices, and can solve the problems of inconsistent adhesive layer thickness and thickness uniformity, low reliability of optical remote sensors, waste of raw materials and aerospace resources, etc. problems, achieve the effect of shortening the development cycle, reducing development and launch costs, and ensuring the bonding strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

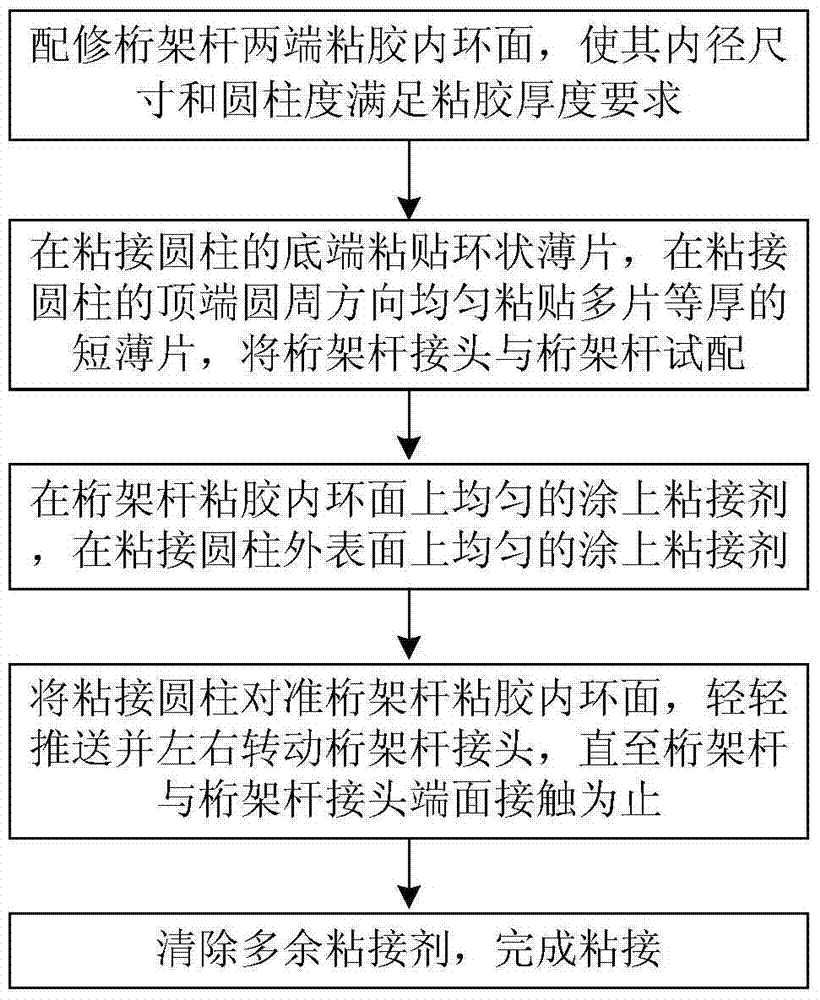

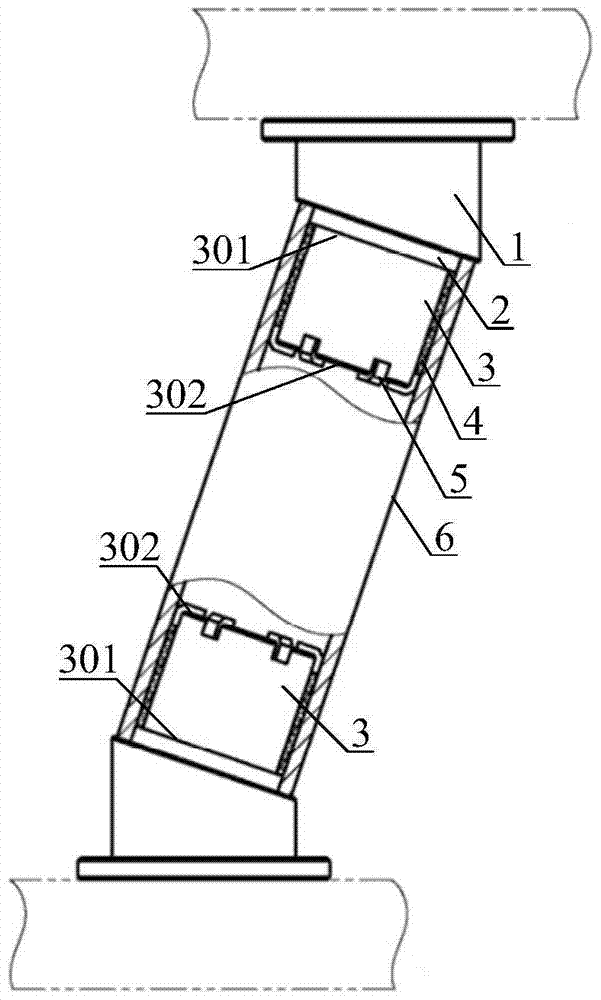

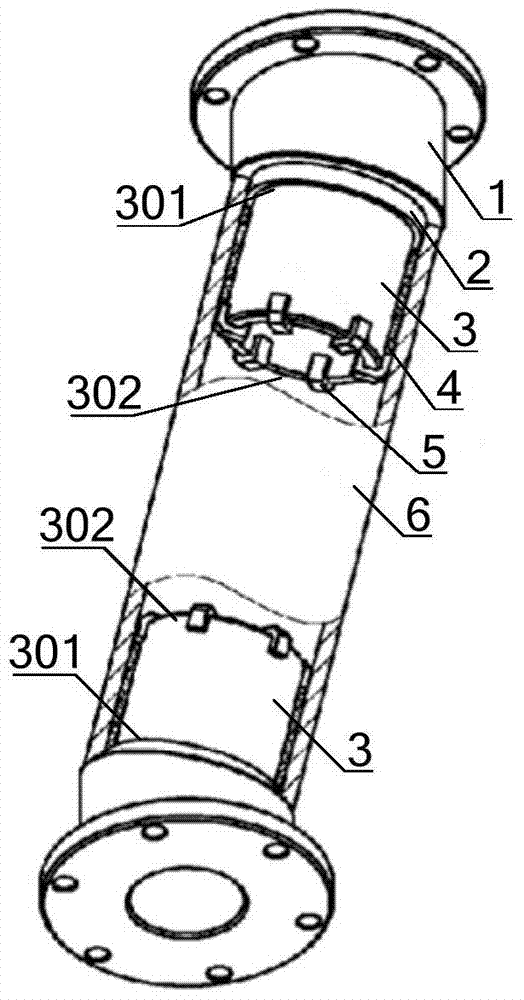

[0020] See attached figure 1 , attached figure 2 And attached image 3 A method for controlling the thickness of the adhesive layer of the space truss bar of the optical remote sensor of the present invention comprises the following steps:

[0021] Step 1: Repair the inner ring surface of both ends of the truss rod 6 with glue, so that the inner diameter and cylindricity meet the glue thickness requirements;

[0022] Step 2: Paste the ring-shaped sheet 2 on the bottom end 301 of the bonding cylinder 3, and evenly paste multiple short sheets 5 of equal thickness in the circumferential direction on the top 302 of the bonding cylinder 3, and test match the truss rod joint 1 with the truss rod 6 , until the truss rod joint 1 can smoothly rotate one circle at a uniform speed in the truss rod 6 without shaking;

[0023] Step 3: Apply adhesive 4 evenly on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com