Method and computer program for analyzing wall thickness distribution of pipes

A technology of wall thickness and pipeline, applied in rolling mill control devices, length measuring devices, instruments, etc., can solve the problem of not giving wall thickness deviation, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

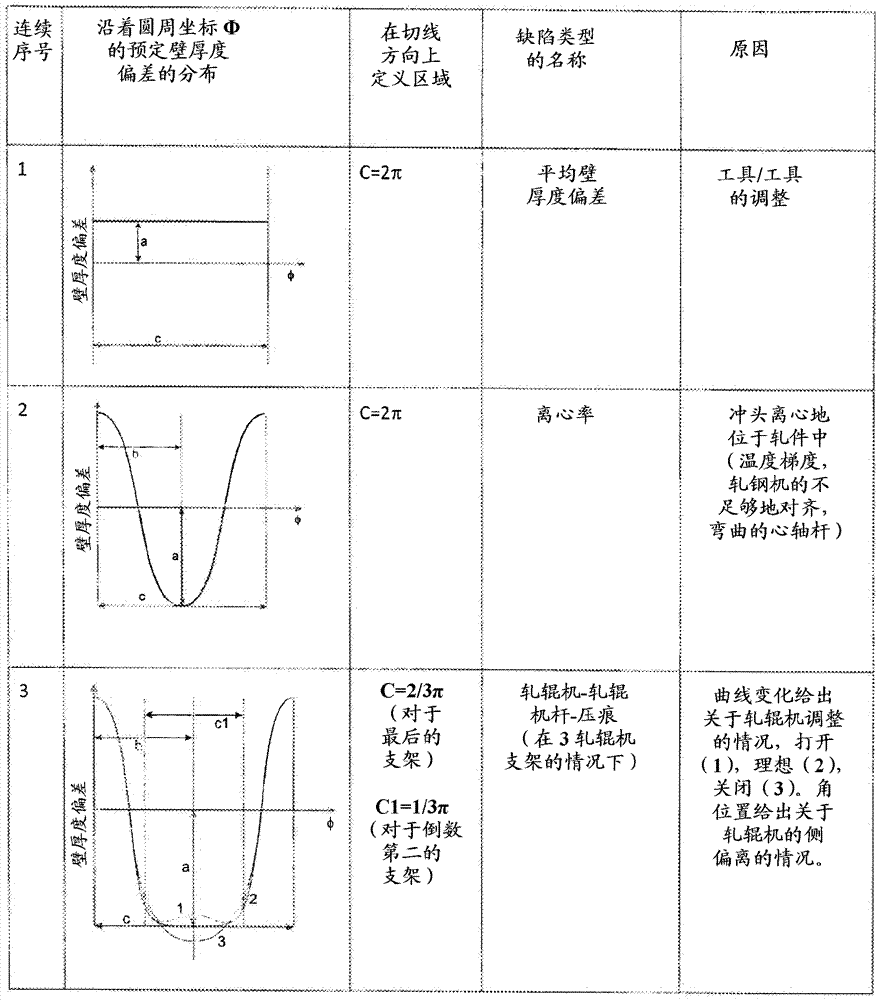

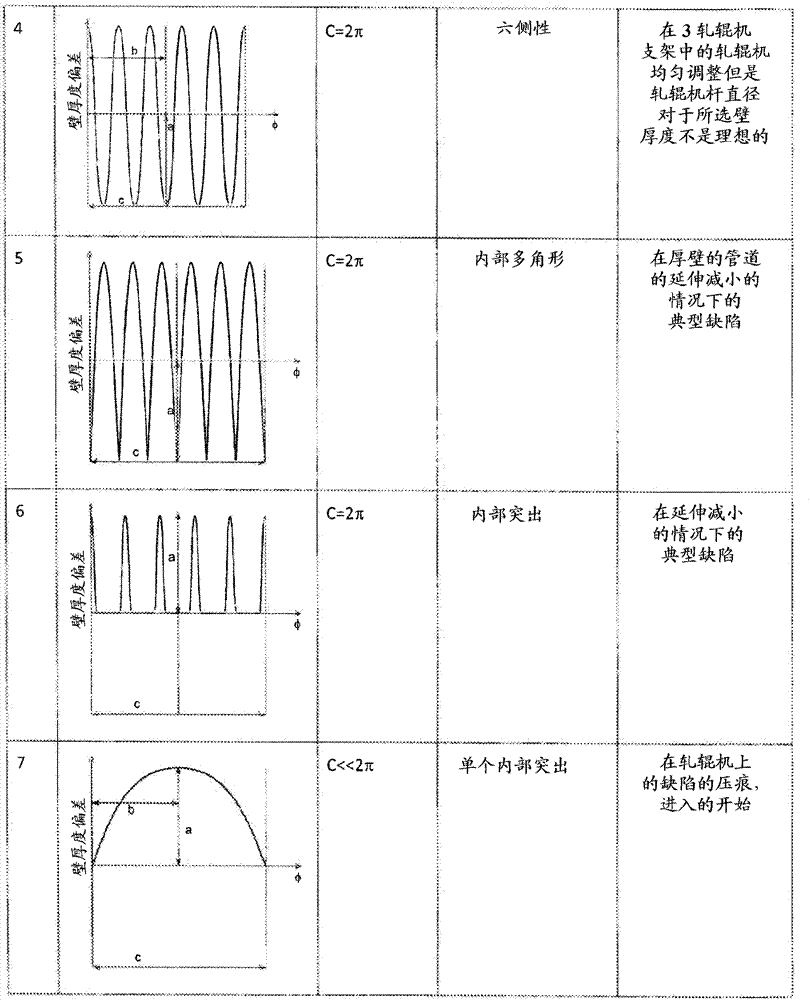

[0023] The method according to the invention is described in detail below on the basis of the accompanying drawings in the form of an embodiment

[0024] The method according to the invention for analyzing the wall thickness distribution of a pipe 10 comprises the following steps:

[0025] In a first step, the profile of the deviation of the wall thickness of the pipe in the tangential direction Φ is determined from a predetermined nominal thickness profile. exist figure 1 This actual distribution of the deviations in the wall thickness is denoted by reference numeral 1 . The curve with reference number 1 relates to the nominal wall thickness distribution in figure 1 not drawn in; its in figure 1 Corresponds to a circle with a constant radius about the midpoint, where the radius of the circle does not differ from that of the pipe in figure 1 The constant radius for outer contour 2 is shown in .

[0026] According to the method according to the invention, the determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com