Reverse gas infrared radiation device and reverse gas radiation method

A technology of infrared radiation and gas, which is applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of unsuitable materials, incomplete combustion, and excess air, so as to suppress excessive internal temperature and solve incomplete combustion. The effect of completely eliminating the hidden danger of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

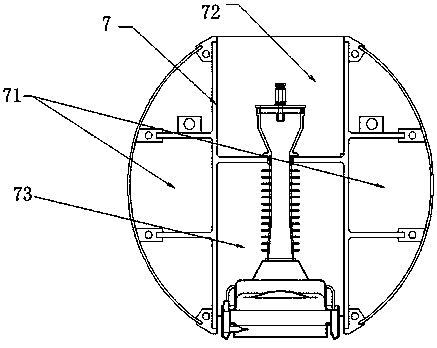

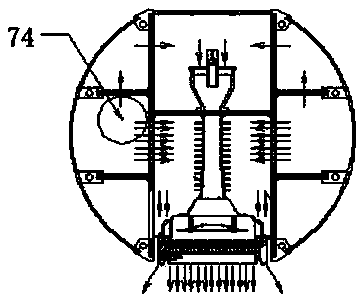

[0068] A reverse gas radiation device, including a box 7 and a radiation generator, the box 7 is installed outside the radiation generator, the radiation generator includes an entrance 1, an injection tube 2, from top to bottom, Diffusion chamber 3, combustion part 4; Injection port 1 includes gas injection port 11 and air inflow port 12, Injection port 1 is connected to an external gas supply device, and gas is injected with a low-power gas nozzle; The outer wall of injection pipe 2 includes cooling fins 23, The cooling fins 23 are uniformly distributed on the outer wall of the ejector tube 2 . The outer edge of the heat sink 23 is a circular sheet protruding; the inner side of the ejector tube 2 is a mixing part 21 and a diffusing part 22 from top to bottom, the mixing part 21 is a vertical hollow cylinder, and the diffusing part 22 is a vertical hollow cone Shaped cylinder, there is an outward inclination angle of 8° between the diffusion part 22 and the mixing part 21. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com