Clarification tank, glass article manufacturing device, and glass article manufacturing method

A technology of clarification tank and glass melting, which is applied in the field of glass article manufacturing equipment and clarification tank, and can solve the problems such as the quality decline of glass melting material and the concentration of heterogeneous material layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

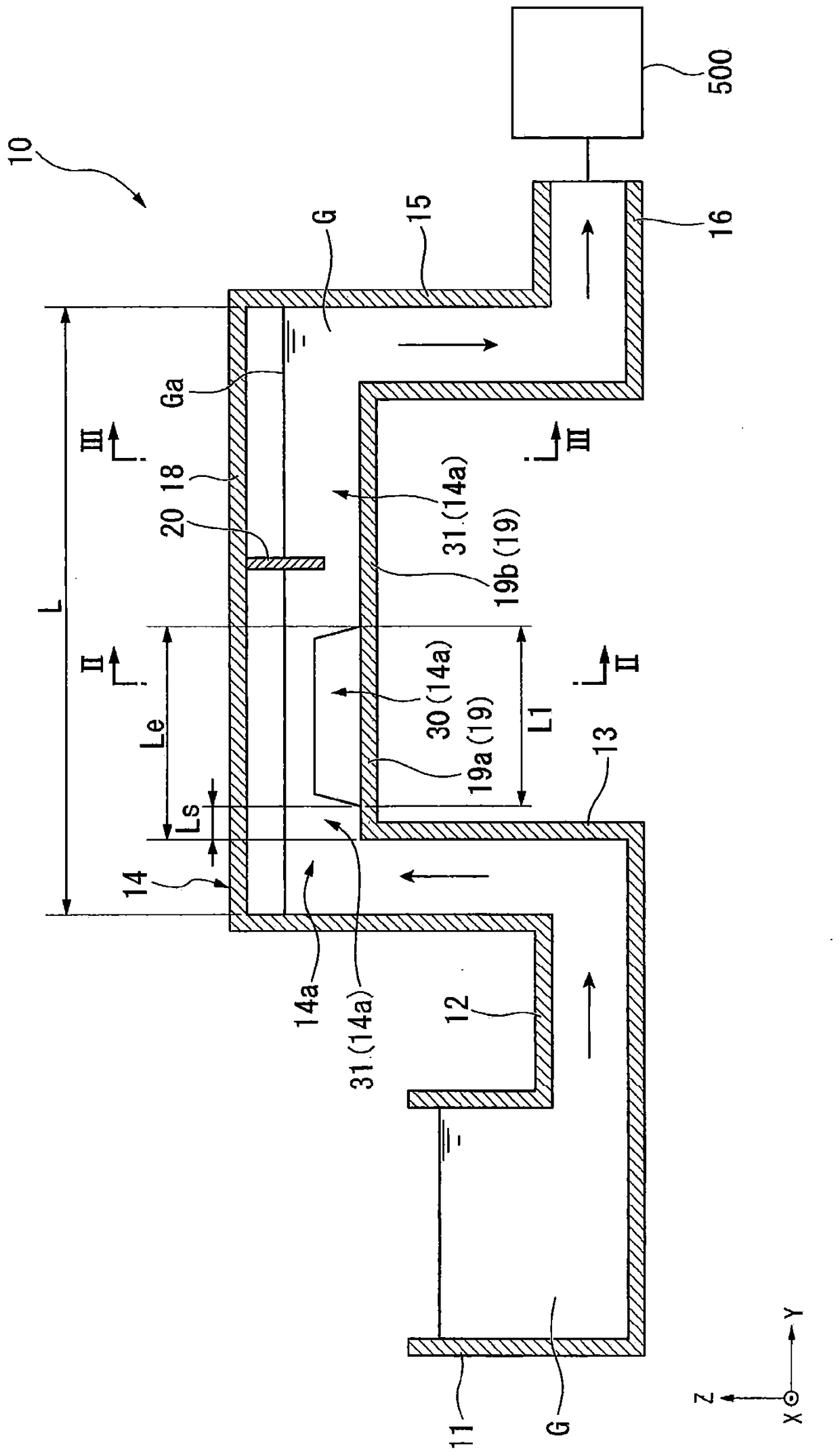

[0060] Such as figure 1 As shown, the glassware manufacturing apparatus 10 of the first embodiment includes a so-called door-type vacuum degassing apparatus. The glassware manufacturing apparatus 10 includes a clarification tank 14 , an ascending pipe 13 , a descending pipe 15 , a barrier plate 20 , a melting tank 11 , a forming device 500 , and a decompression unit not shown.

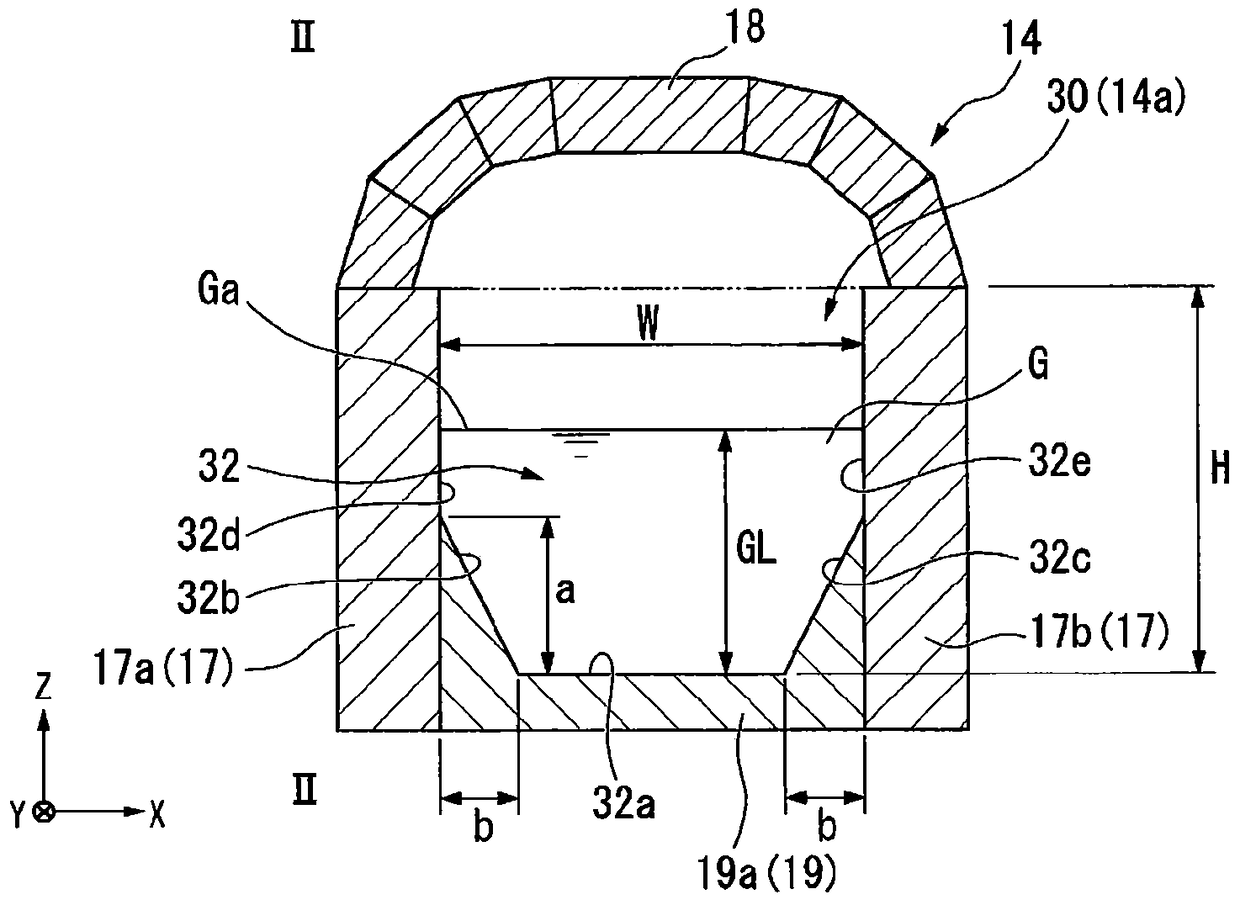

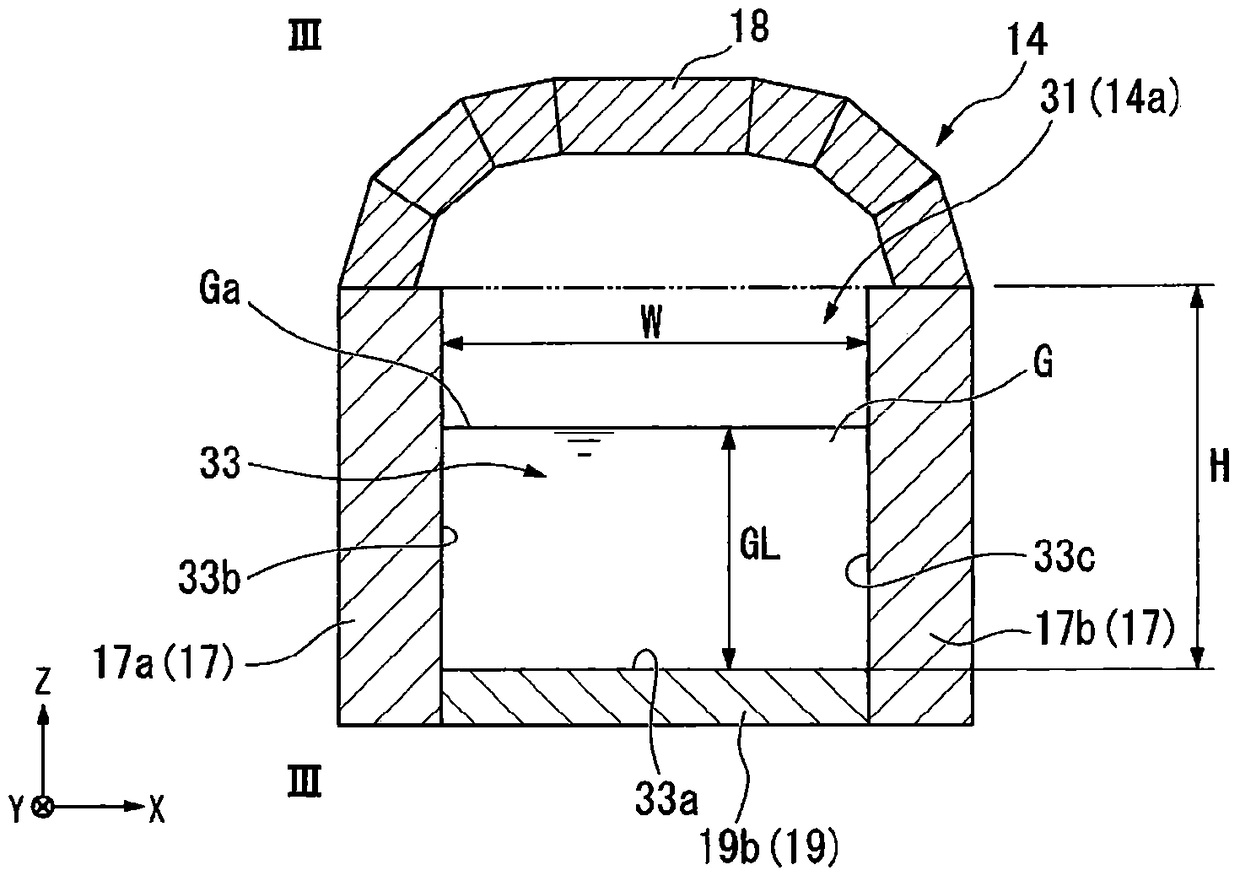

[0061] The clarification tank 14 is formed with a refractory brick. Such as figure 2 and image 3 As shown, the clarification tank 14 is a hollow structure having an inner space surrounded by refractory bricks. That is, the internal space of the clarification tank 14 is surrounded by the side wall part 17, the top part 18, and the bottom part 19, and the said side wall part 17 is formed with the brick 17a and the brick 17b. Brick 17a and brick 17b are rectangular parallelepiped refractory bricks. The top 18 and the bottom 19 are formed by one refractory brick, or a combination of multiple refract...

no. 2 approach

[0125] The glass article manufacturing apparatus 210 of 2nd Embodiment is a glass article manufacturing apparatus which has what is called a flat high-temperature clarification tank.

[0126] In addition, the same structure as 1st Embodiment may be attached|subjected to the same code|symbol in drawing, and description is abbreviate|omitted.

[0127] Such as Figure 6 As shown, the glass article manufacturing device 210 includes a clarification tank 214 , a barrier plate 20 , electrodes (heating devices) 40 a , 40 b , 40 c , a melting tank 11 and a forming device 500 .

[0128]The clarification tank 214 is a hollow structure having an inner space surrounded by refractory bricks. The flow path 214a of the molten glass G is formed in the internal space of the clarification tank 214. As shown in FIG. The flow path 214 a has a polygonal flow path portion 230 and a rectangular flow path portion 231 .

[0129] The polygonal flow path portion 230 is the same as the polygonal flow p...

Embodiment 1

[0148] Embodiments 1-1 to 1-4 were compared with comparative examples 1-1 to 1-3 and the reference example through a simulation test. As a result, it was confirmed that convection of molten glass can be suppressed by forming the cross-sectional shape of the molten glass flow path into a polygonal shape of not less than a hexagon and satisfying the formula (4). In Table 1, each parameter of Examples 1-1 to 1-4, Comparative Examples 1-1 to 1-3, and a reference example is shown.

[0149] Table 1

[0150]

[0151] The cross-sectional shape of the glass molten flow path at the polygonal flow path portion of Example 1-1 is as follows: Figure 7 As shown in (A), it is formed in the same hexagonal shape as the molten glass channel 32 of the first embodiment.

[0152] The cross-sectional shape of the glass molten flow path at the polygonal flow path portion of Example 1-2 is as follows: Figure 7 As shown in (B), it is formed in the same hexagonal shape as the molten glass flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com