Process method for reworking after TP full lamination

A process method and full lamination technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of difficult rework, low rework yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

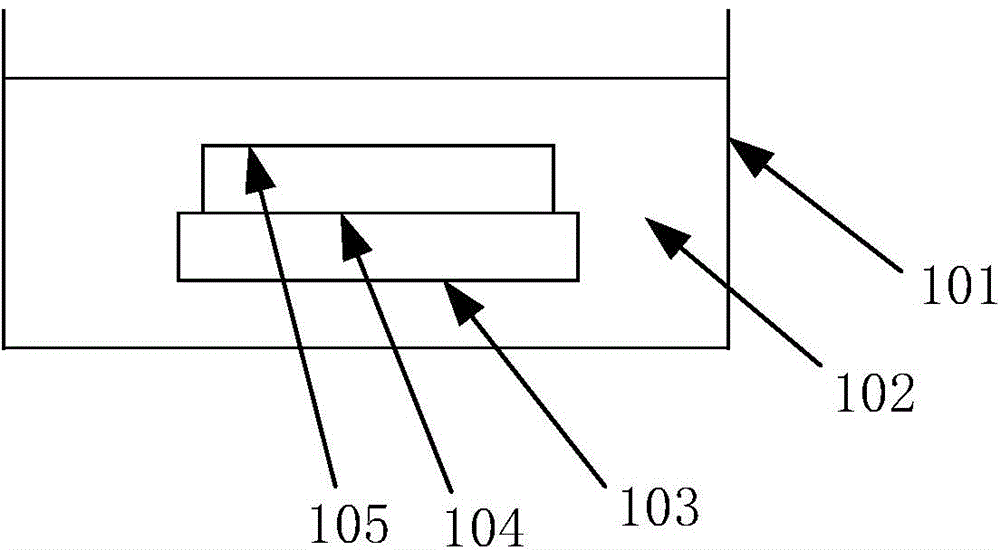

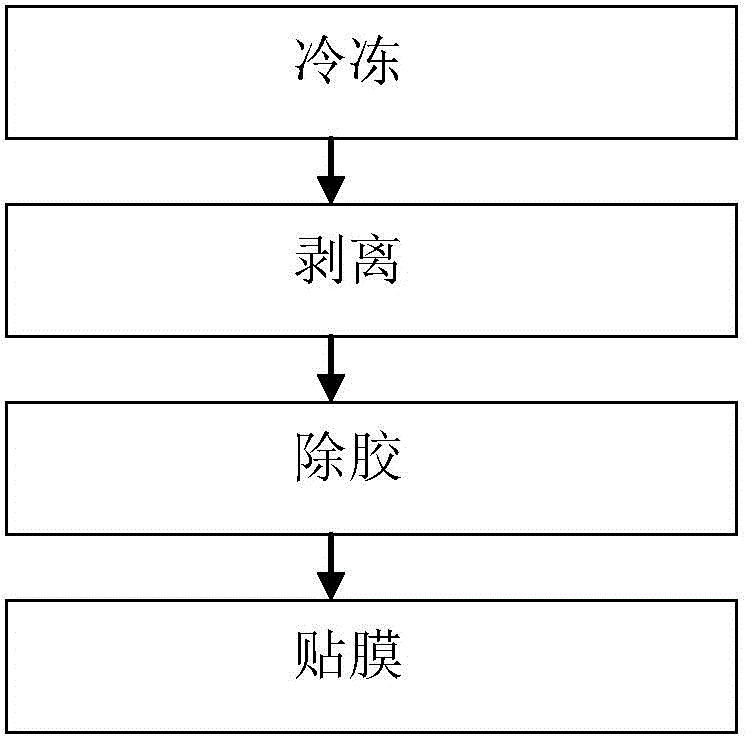

[0017] This embodiment provides a TP full lamination post-rework process, which includes the following steps: figure 2 As shown, first, perform step A: Freeze, seal and package the product to be reworked for ultra-low temperature freezing; wherein, put the reworked product into a freezer in an ultra-low temperature container; figure 1 As shown, the reworked product includes a sensor layer 105 , a cover layer 103 , and OCA or LOCA glue 104 for pasting the sensor layer 105 and the cover layer 103 , by putting the reworked product into a container 101 filled with liquid nitrogen 102 .

[0018] First of all, choose a method that can achieve low temperature freezing, and consider the following aspects: economical aspects; harm to the human body; the difficulty of processing and other comprehensive considerations, we finally choose liquid nitrogen freezing to freeze the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com