A wall panel installation connector and a method for installing the wall panel

A technology of connectors and wall panels, which is applied in the direction of construction and building construction, can solve the problems of changing the failure mode of the main structure, poor deformation capacity and seismic performance, and cracking of concrete slabs under tension, so as to reduce the difficulty of production and construction And cost, good rigidity, safe and reasonable effect of wall panel structure stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

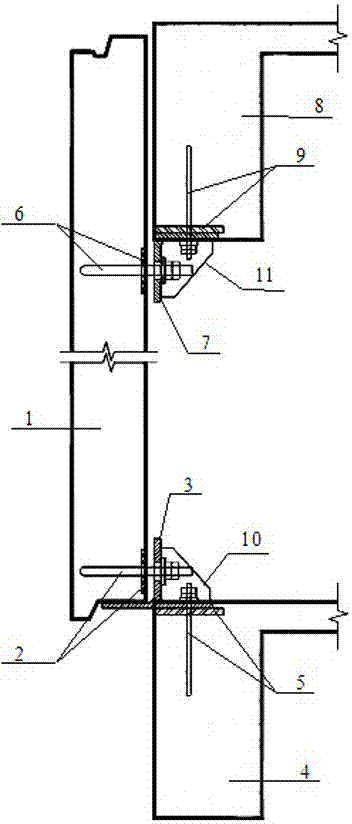

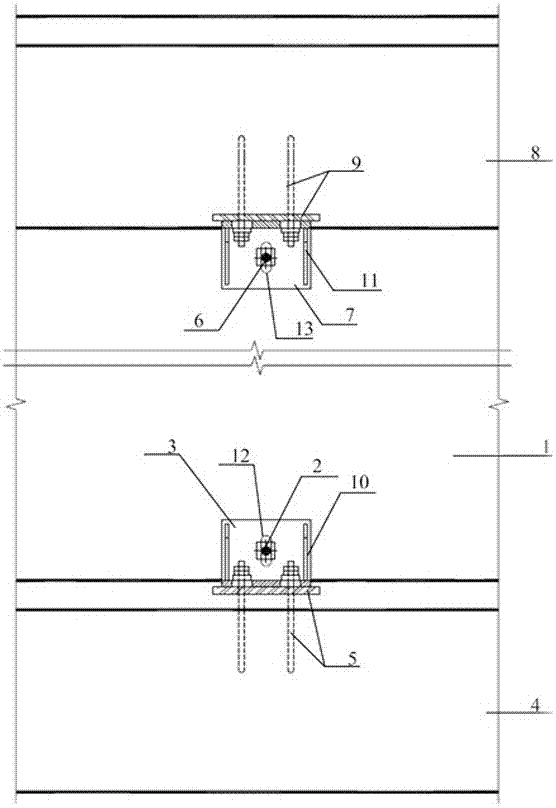

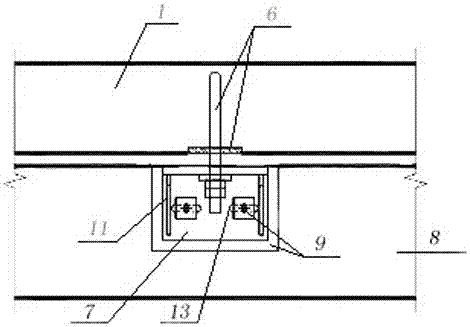

[0034] Such as figure 1 As shown, this embodiment includes a connector A3 and a connector B7. The connector A3 is an inverted T-shaped steel, and the connector B7 is an angle steel. Side flange connection, the upper body 8 is connected to one side of the connector B7 through the main body embedded part B9, the upper side wall of the wall panel 1 is connected to the other side of the connector B7 through the wall embedded part B6, and the lower part of the wall panel 1 The side wall is connected to the web of the connector A3 through the wall embedded part A2, and the bottom of the wall panel 1 is placed on the outer flange of the connector A3.

[0035]When the present invention is used, an inverted T-shaped steel connector A3 is adopted, so that the outer flange of the connector A3 is subjected to the vertical load of the wall panel 1, and the inner flange of the connector A3 bears the vertical downward pulling force of the main embedded part A5 , so that the overall force of...

Embodiment 2

[0037] Such as Figure 1~4 As shown, on the basis of Embodiment 1, this embodiment also includes a reinforcing plate A10 and a reinforcing plate B11, the reinforcing plate A10 is fixed between the web and the flange of the connector A3, and the reinforcing plate B11 is fixed on Bending part of connector B7. For the specific situation in the actual installation process, i.e. factors such as the installation size and load of the wall panel 1, the connector A3 and the connector B7 are reinforced, thereby increasing the scope of use of the present invention; the wall embedded part A2 and the wall Embedded part B adopts threaded anchor gasket and anchor bolt, and both the anchor gasket and anchor bolt are pre-embedded in the wall panel 1, and the anchor bolt is adjusted according to the distance between the upper body 8 and the lower body 4 during installation. The bolt can adjust the position of the wall panel 1 through the web of the connecting piece A3 and the vertical oval hol...

Embodiment 3

[0039] Such as figure 1 , Figure 5 As shown, this embodiment is based on Embodiment 1, between the anchor gasket of the wall embedded part A2 and the web of the connector A3, and the anchor pad of the wall embedded part B6 Sliding pads 14 are provided between the sheet and the side wall of the connecting piece B7. The installed sliding gasket 14 improves the deformation of the connection between the wall panel 1 and the main structure while ensuring the stable connection between the wall embedded part A2 and the connecting part A3, and the wall embedded part B6 and the connecting part B7. ability, so that the wall panel 1 has a better earthquake resistance, and reduces the influence of the wall panel 1 on the rigidity of the main structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com