Face-to-face matched angular contact ball bearing and matching method thereof

A contact ball, supporting angle technology, applied in rolling contact bearings, bearings, bearing components, etc., can solve the problem of cumbersome preloading operation, achieve the effect of simple installation process, avoid grinding, and improve overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

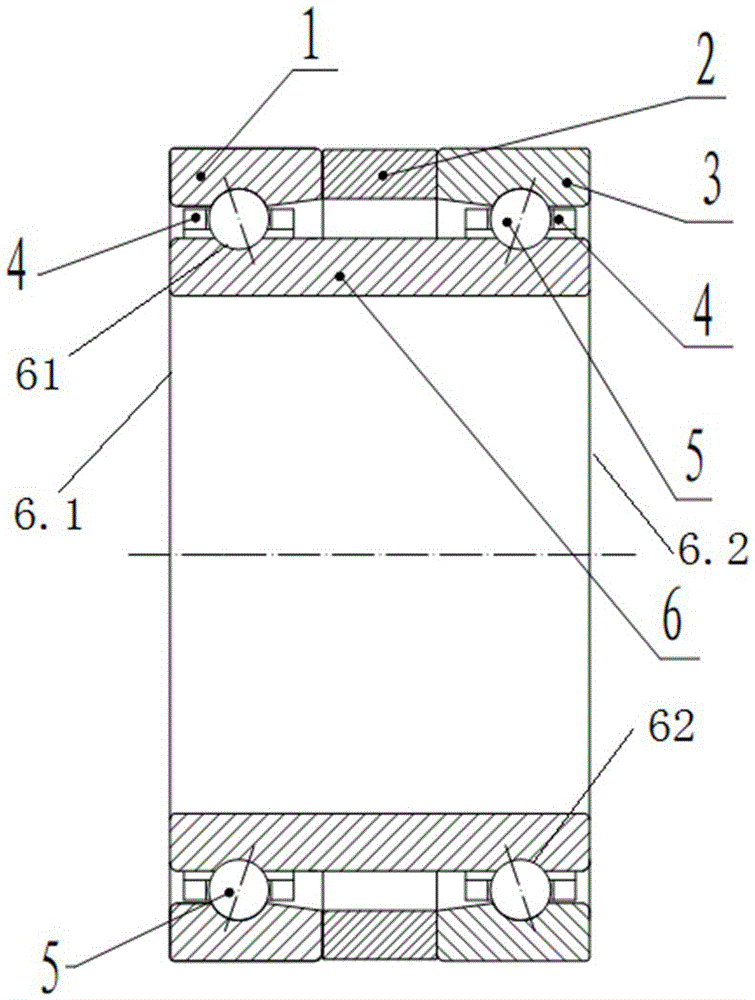

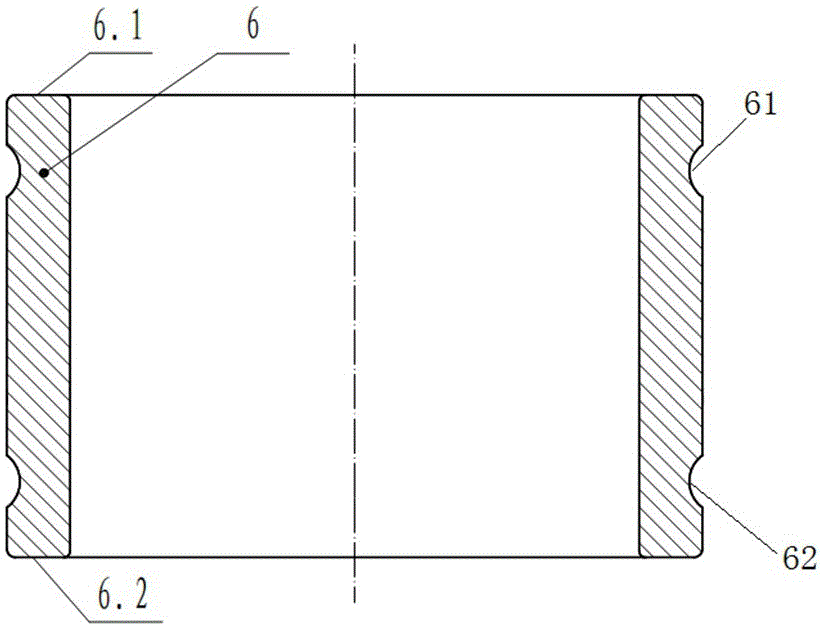

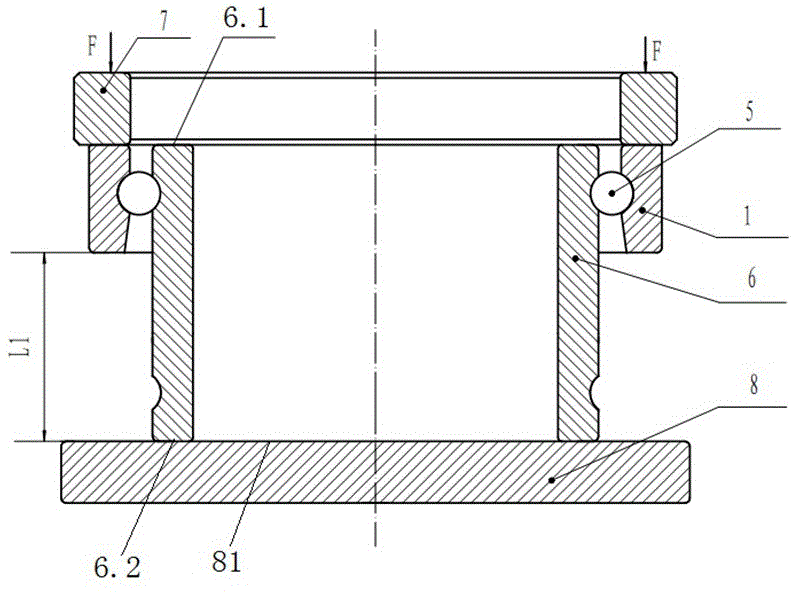

[0020] Such as figure 1 , figure 2 As shown, an embodiment of a face-to-face assembled angular contact ball bearing. The face-to-face assembled angular contact ball bearing in this embodiment includes an inner ring 6 extending axially along the front and rear directions. The outer peripheral surface of the inner ring 6 is provided with a The first outer channel 61 and the second outer channel 62 ′, which are arranged at intervals in the front and rear directions, are arranged one-to-one in the axial direction of the inner ring and close to the two ends of the inner ring in the axial direction. The inner ring 6 is equipped with a first outer ring 1 corresponding to the first outer channel 61 and a second outer ring 3 corresponding to the second outer channel 62. The design parameters of the two outer rings are the same. The direction is arranged at intervals, and an outer spacer 2 is sandwiched between the two outer rings. There are inner grooves on the inner peripheral surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com