Anti-rolling water tanks with side ports and anti-rolling method thereof

A technology for anti-rolling water tanks and water tanks, which is applied in the direction of reducing the movement of ships through displacement, which can solve the problems of strong air compressibility, structural damage, not suitable for large-tonnage ships, etc., and achieve easy operation, control devices and transmission devices. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

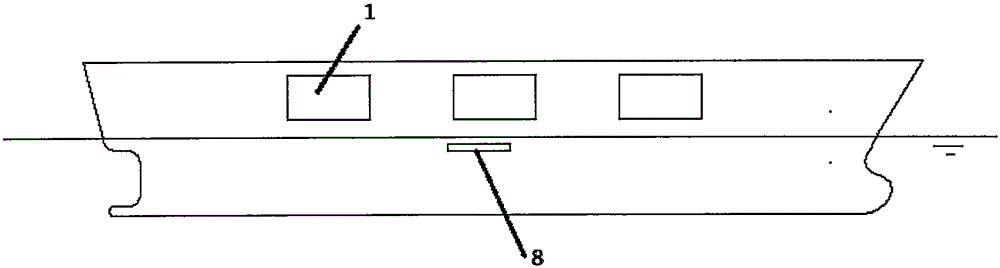

[0017] Such as figure 1 As shown, it includes the right cabin door 1 and the pressure sensor 8.

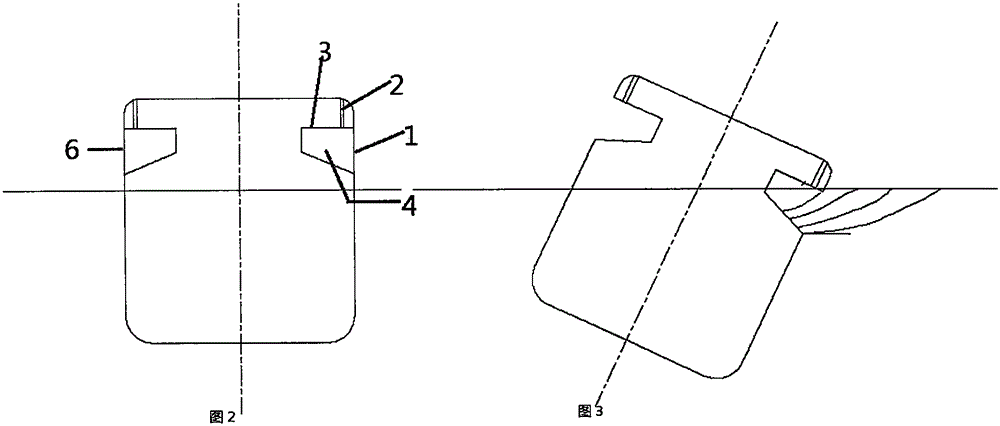

[0018] Such as figure 2 Shown, comprise the cabin 4 of anti-rolling water tank, left cabin door 6, water tank exhaust and drainage pipe 2, water tank roof 3.

[0019] Such as Figure 8 As shown, it includes a rotating shaft 5 , a rotor 7 , a drive shaft 13 , a controller 9 , an angular velocity control gyro 10 , and a discontinuous longitudinal bulkhead 14 .

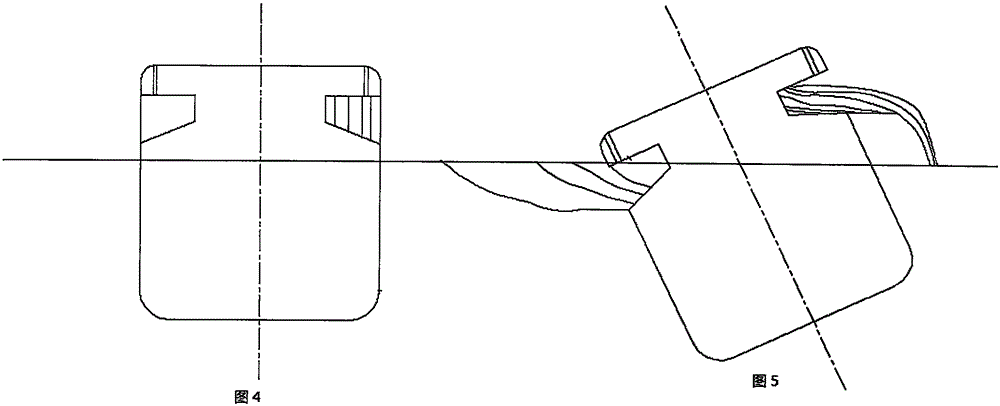

[0020] Such as Figure 10 As shown, it includes ribs 11 on the cabin door and openings 12 on the ribs.

[0021] Described below is the working principle and operation process of the anti-rolling water tank of the present invention.

[0022] Such as figure 1 As shown, left and right symmetrical water tanks are set on both sides of the ship, and front and rear symmetrical water tanks are set at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com