A remote real-time monitoring system for cement rotary kiln masonry

A real-time monitoring and monitoring system technology, applied in transmission systems, closed-circuit television systems, time registers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

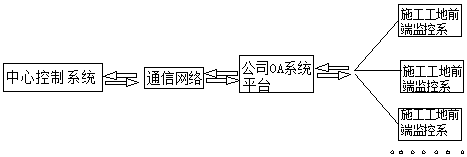

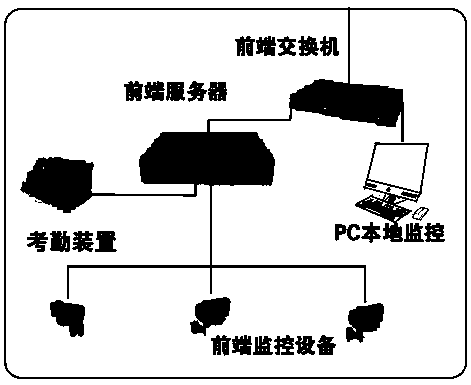

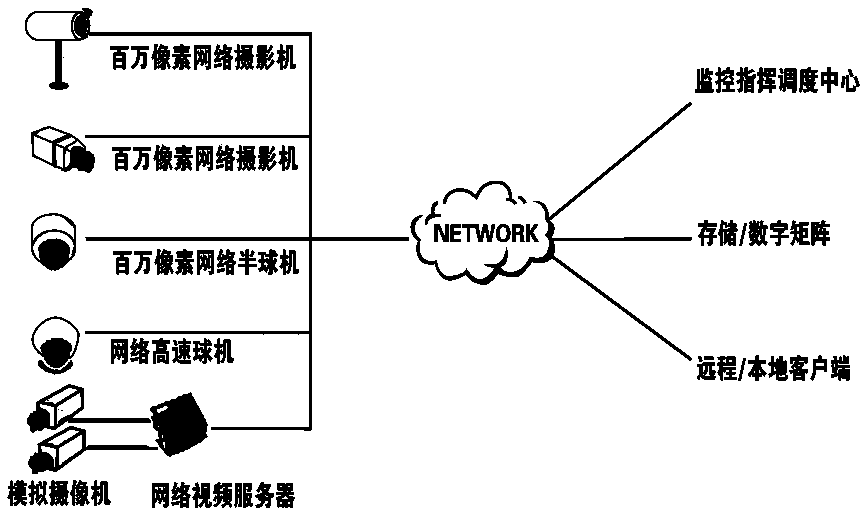

[0031] Embodiment 1: as figure 1 , 2 , 3, 4, and 5 show a remote real-time monitoring system for cement rotary kiln masonry, which is suitable for remote real-time monitoring applications at furnace construction sites. The front end, the company's OA system platform and the communication network are composed of four parts. It can satisfy the company's safety supervision and management personnel to remotely control and manage various construction sites in the monitoring center, including remote audio monitoring, electronic map display, remote audio intercom, and remote alarm. Functions such as control, hierarchical management, information release, and file upload and release. The communication network is provided with a total data server, a distribution server, a management server, and an authentication server;

[0032] The furnace construction site front-end monitoring system includes a PC host, a front-end server, a front-end data switch, a front-end monitoring device, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com