Two-stage extensible type electric soldering iron cooling frame

一种电烙铁、伸缩式的技术,应用在烙铁、辅助装置、金属加工设备等方向,能够解决时间短暂、烙铁头易氧化、能源浪费等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

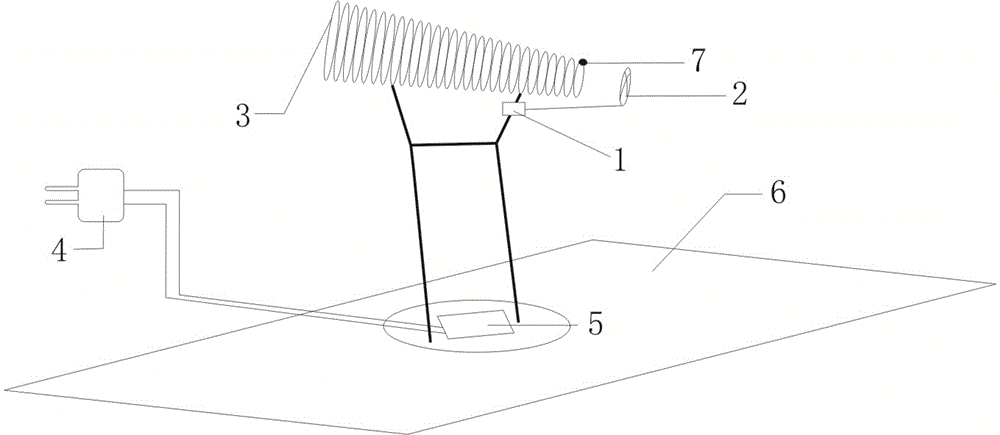

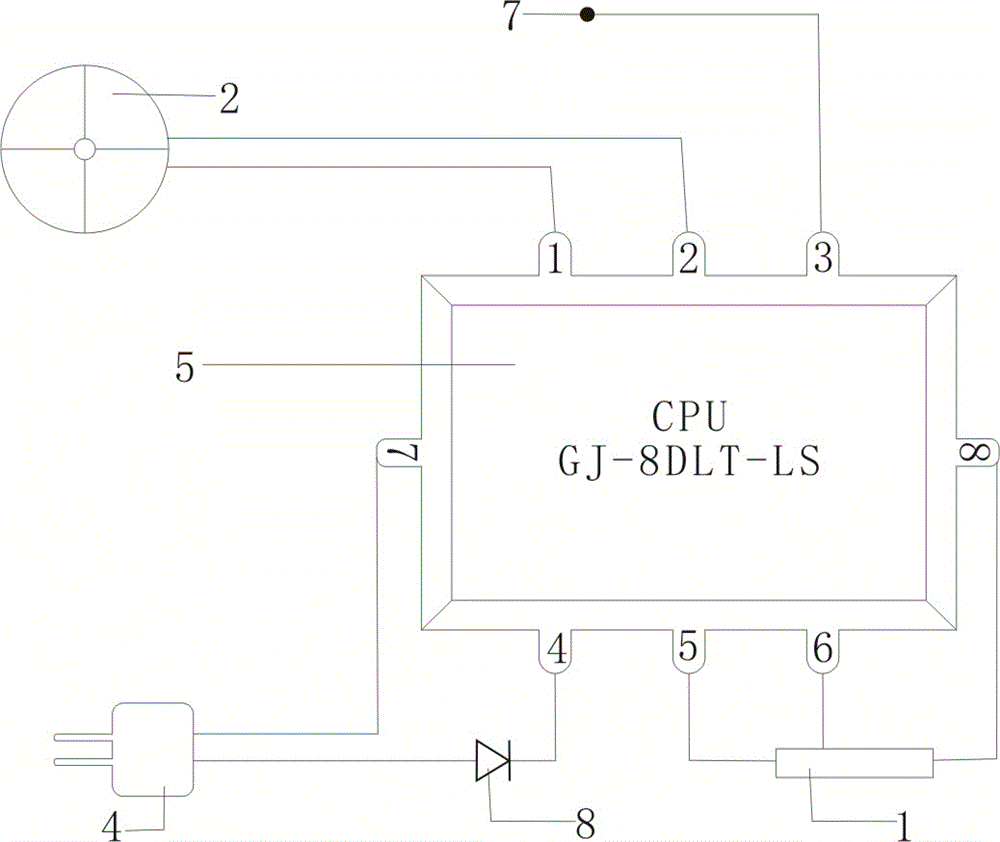

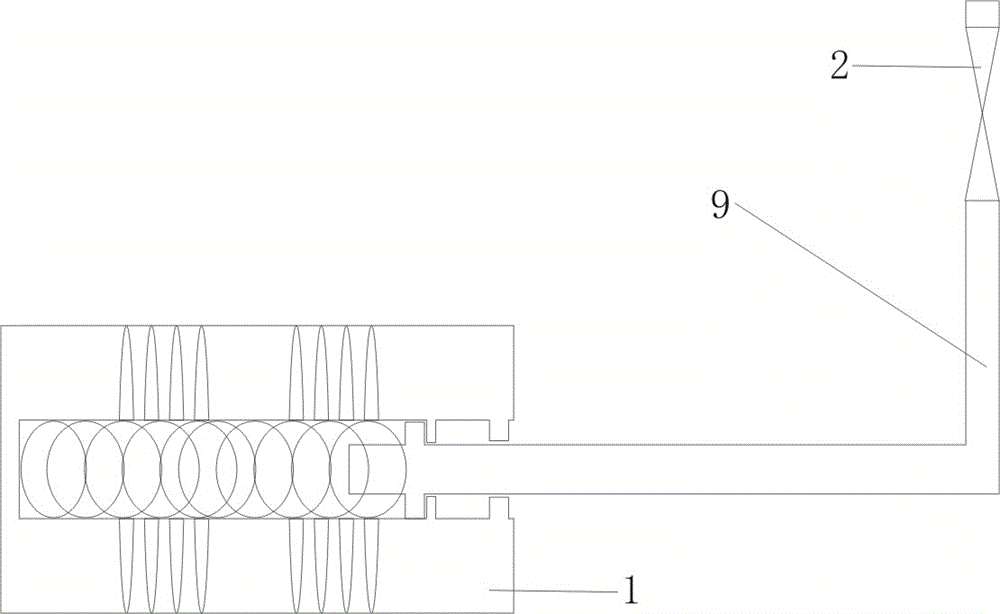

[0023] The present invention is a two-stage telescopic electric soldering iron heat dissipation stand, which is composed of: solenoid valve 1, fan 2, sleeve 3, plug 4, control module 5, soldering iron stand 6, sensor 7, diode 8, and pull rod 9.

[0024] in figure 1 The soldering iron stand 6 is connected with the sleeve 3 by means of a support rod. A sensor 7 is designed at the end of the sleeve 3. The control module 5 is installed in the middle of the support bar above the soldering iron stand 6. The control module 5 leads out a power plug 4, and the right support A solenoid valve 1 is installed on the frame near the sleeve 3, and the solenoid valve 1 is connected to the fan 2 through a tie rod 9.

[0025] in figure 2 In, the first and second pins of the control module 5 are connected to the fan 2, the third pin is connected to the sensor 7, the fourth and seventh pins lead to a power plug 4, and the fourth pin and the plug 4 are connected in series. Connect a diode 8. The fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com