Fully automatic fixture flow storage platform equipment and flow storage method thereof

A flow storage and fixture technology, applied in the field of fixtures, can solve the problems of high labor intensity, low product quality, messy placement, etc., achieve strong product compatibility, improve product quality, and avoid manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

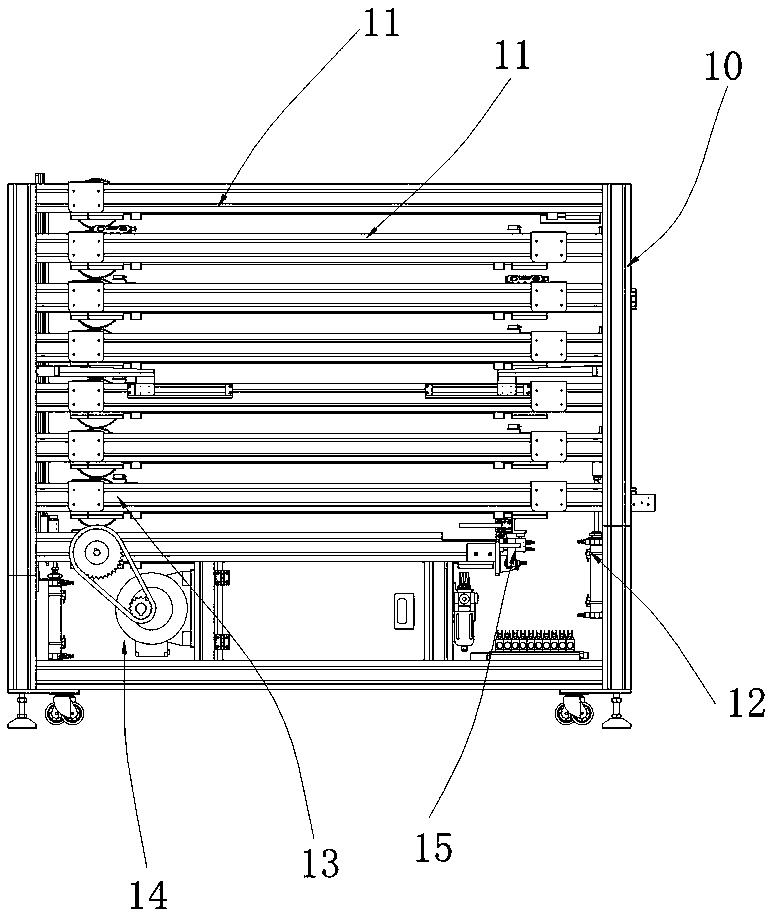

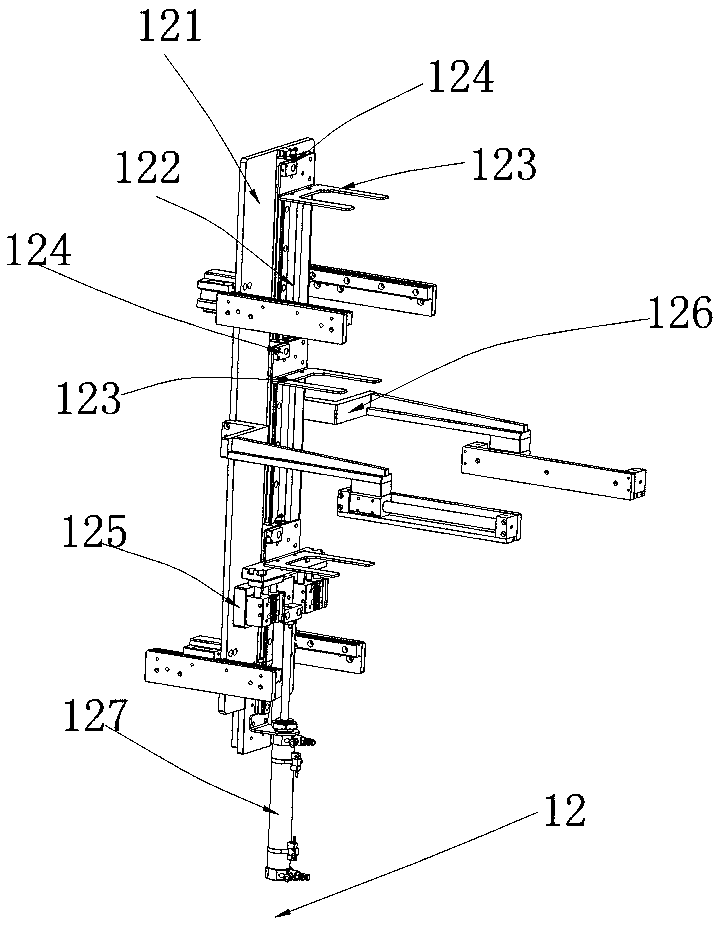

[0038] see figure 1 , the fully automatic fixture flow storage platform equipment provided by the present invention includes a frame 10 and a multi-layer material layer 11 distributed in the frame 10 from top to bottom in sequence, and useful The lifting mechanism 12 for realizing the flow of the fixture between the upper and lower material layers;

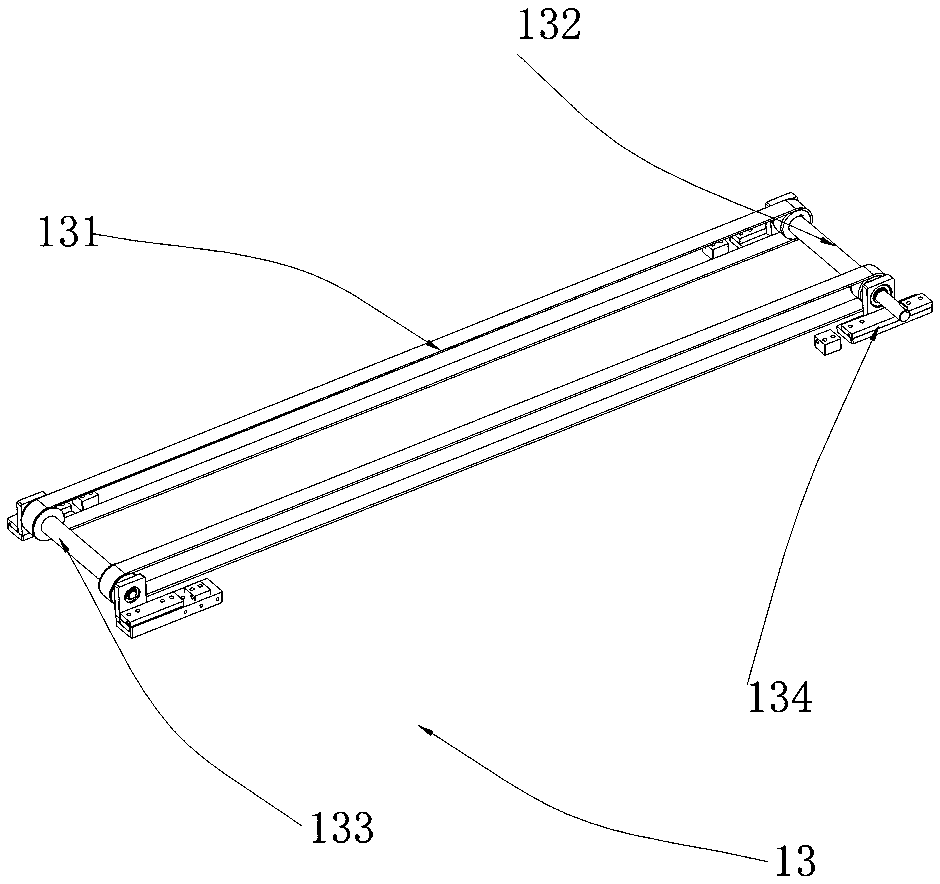

[0039] On each layer of material layer 11, a conveying mechanism 13 for conveying clamp fixtures is installed, and on the frame 10, a transmission mechanism 14 for realizing the constant velocity motion of the conveyor belts of different layers of material layers is installed, and the transmission mechanism 14 is connected with the conveying mechanism. The mechanism 13 is driven and connected, and after the transmission mechanism 14 is driven, the movement of the odd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com