A hose arc cutting machine

A hose and arc cutting technology, which is applied in metal processing and other directions, can solve the problems of low work efficiency and poor flatness of arc ports, and achieve high work efficiency, good arc consistency, and neat arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

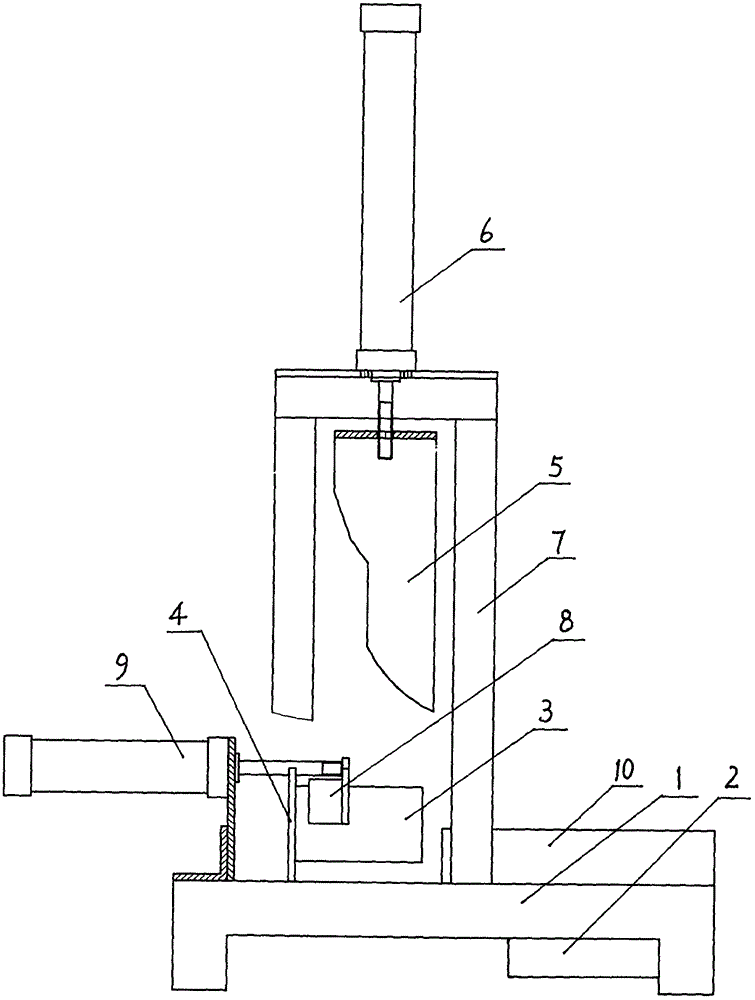

[0009] like figure 1 The hose arc cutting machine shown includes a base 1, an electrical control device 2, and the electrical control device 2 is installed on the base 1; the base 1 is provided with a hose positioning device, a hose arc cutting device and a waste material pushing device; the hose The positioning device is composed of an outer circular positioning groove 10 and a positioning cylinder 3. The outer circular positioning groove 10 is arranged in the upper plane of the base 1. The positioning cylinder 3 is installed on the base 1 at one end of the outer circular positioning groove 10 through the mounting plate 4. The outer circular positioning groove The center of the arc concave surface of 10 is concentric with the positioning cylinder 3, and one end surface of the positioning cylinder 3 is installed on the mounting plate 4, and there is a radial gap between the outer cylindrical surface of the lower side of the positioning cylinder 3 and the arc surface of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com