Sliding 3D printing device and printing method thereof

A 3D printing and sliding technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of high cost, high use and maintenance costs, low printing and forming accuracy of SLA three-dimensional printing system, and achieve high printing speed Fast, low manufacturing cost, good printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

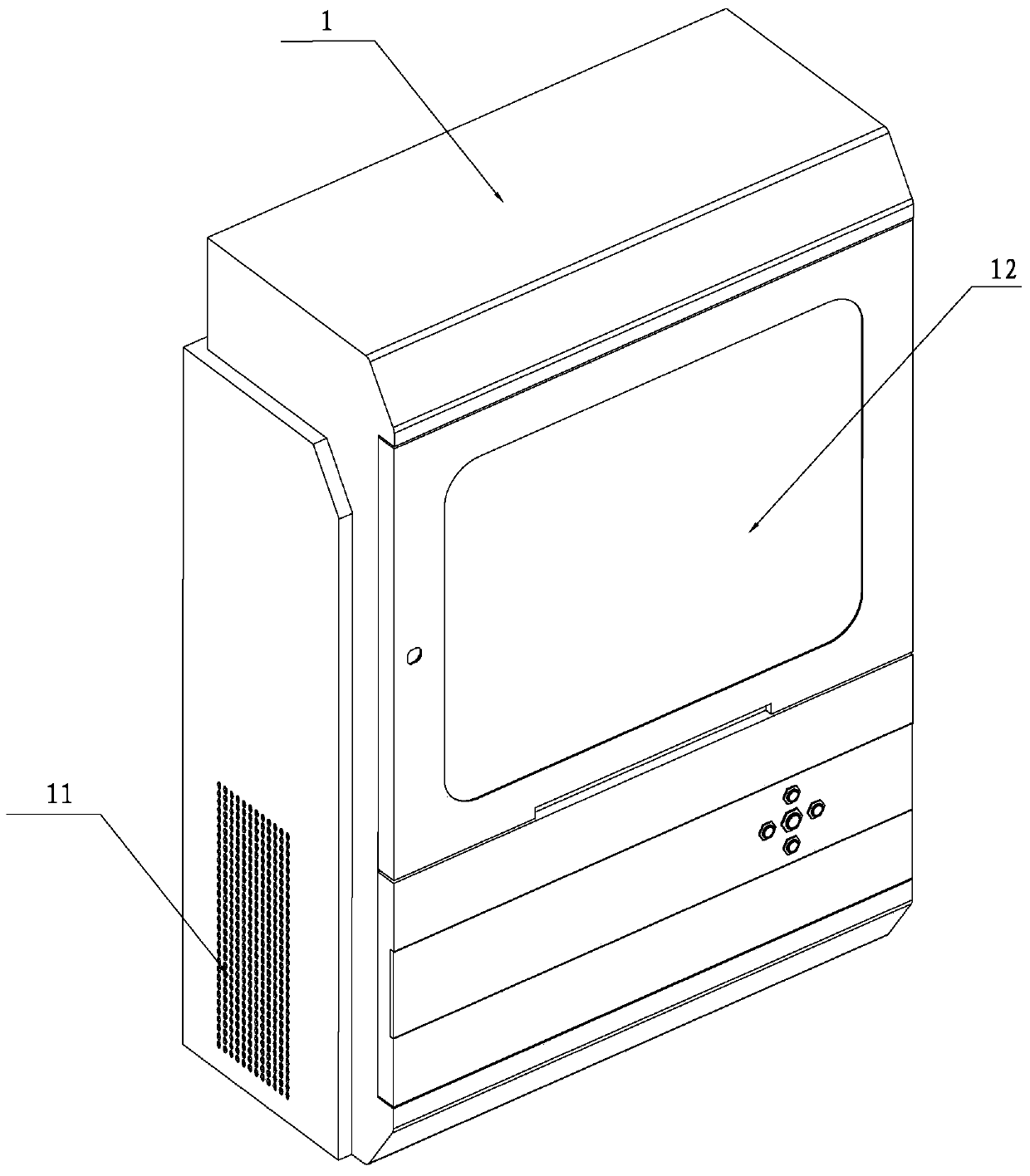

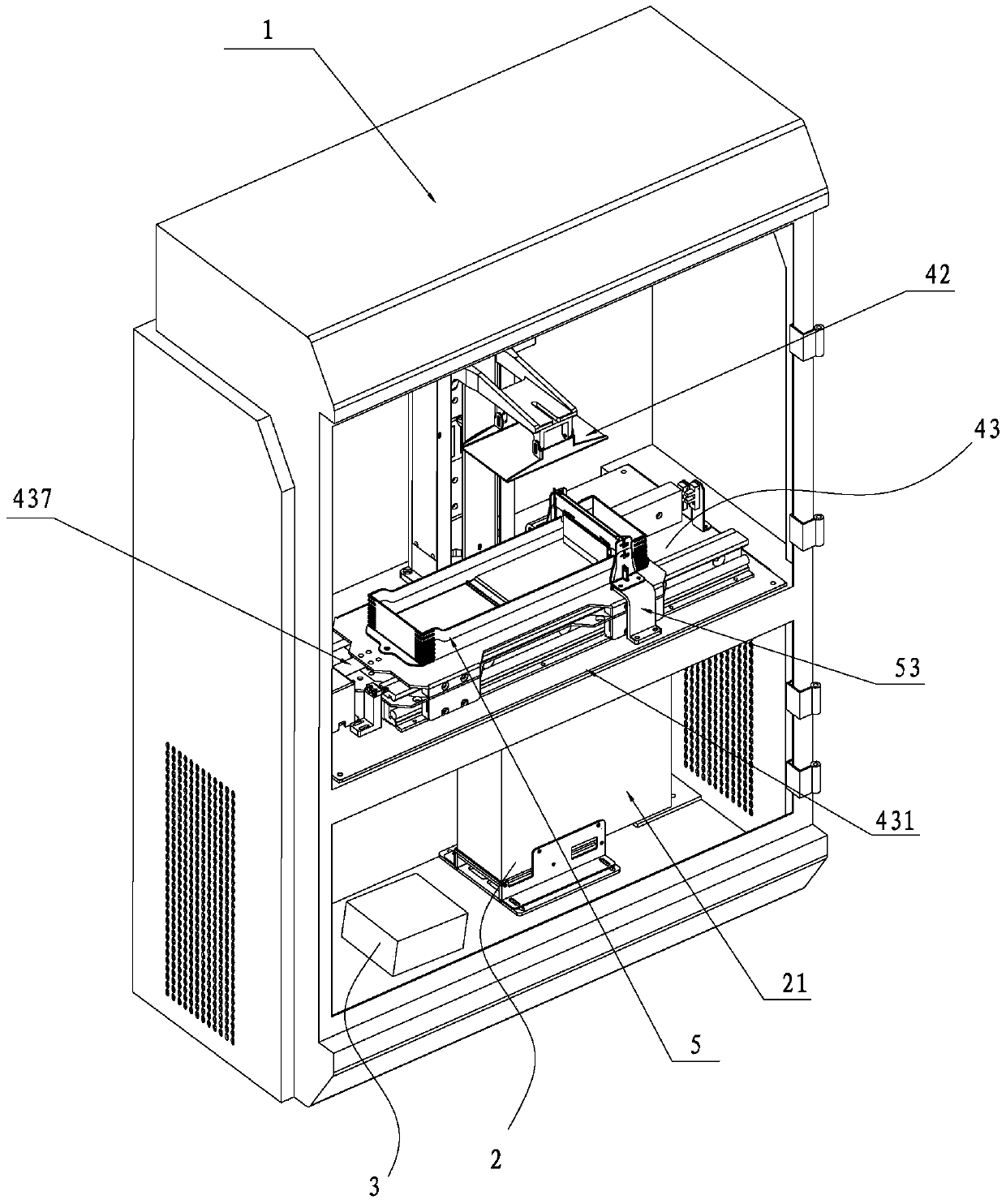

[0034] Such as Figure 1-2 As shown, the sliding 3D printing device includes a box body 1, and an exposure mechanism 2, a control mechanism 3 and a printing mechanism 4 arranged in the box body 1, wherein the exposure mechanism 2 is installed at the lower end of the box body 1, and the box body The two sides of the lower end of 1 are provided with cooling holes 11 for heat dissipation of the exposure mechanism 2, and the printing mechanism 4 is installed on the upper end of the box body 1. The control mechanism 3 is used to control the exposure mechanism 2 and the printing mechanism 4 . The upper end of the box body 1 is provided with a transparent window 12 for observing the printing situation of the printing mechanism 4 .

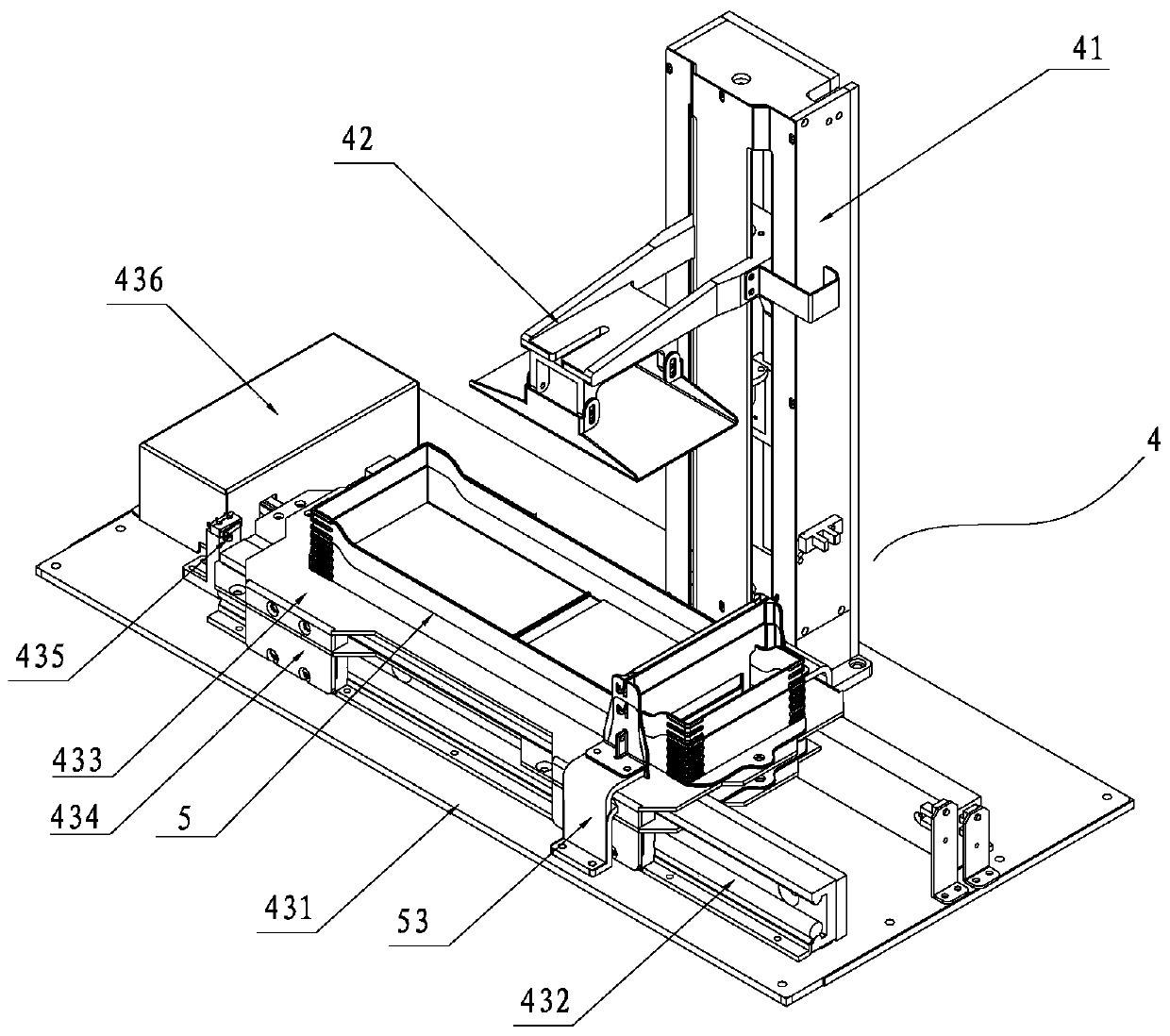

[0035] The printing mechanism 4 includes a module 41, a printing platform 42 slidably installed on the module 41, and a liquid holding assembly 43 located at the bottom of the module 41; plate 431, the mounting plate 431 is provided with a guide rail 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com