Fluid pumping device with split flow structure

A fluid and structural technology, applied in the field of pneumatic tools, can solve problems such as reducing the strength of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

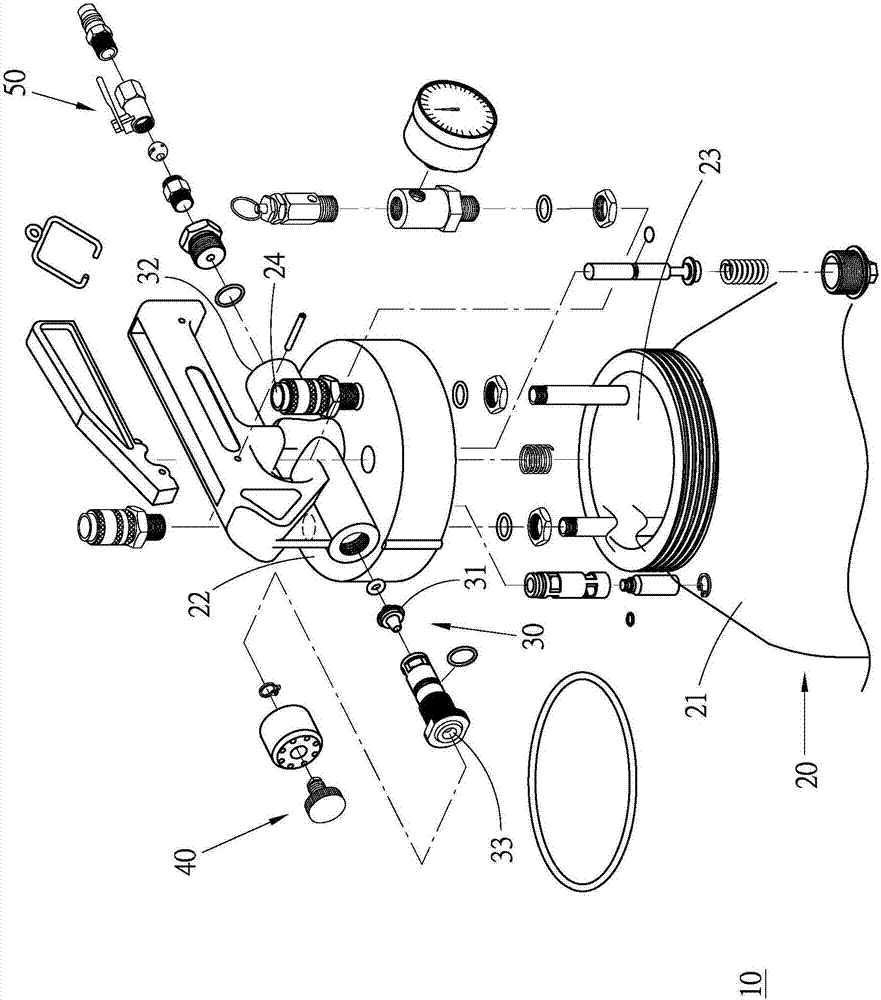

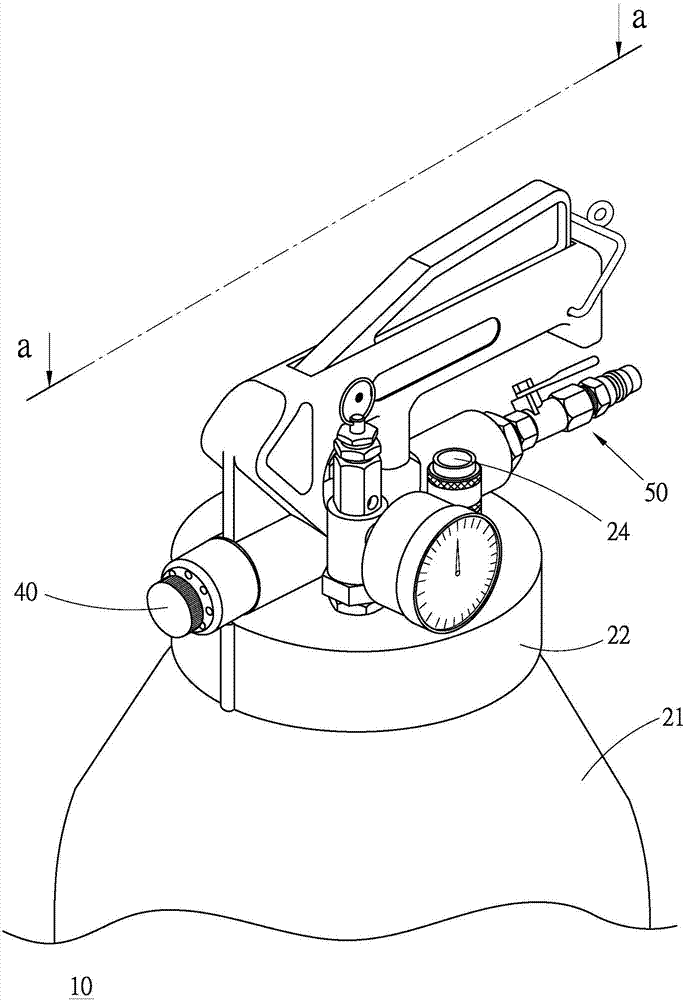

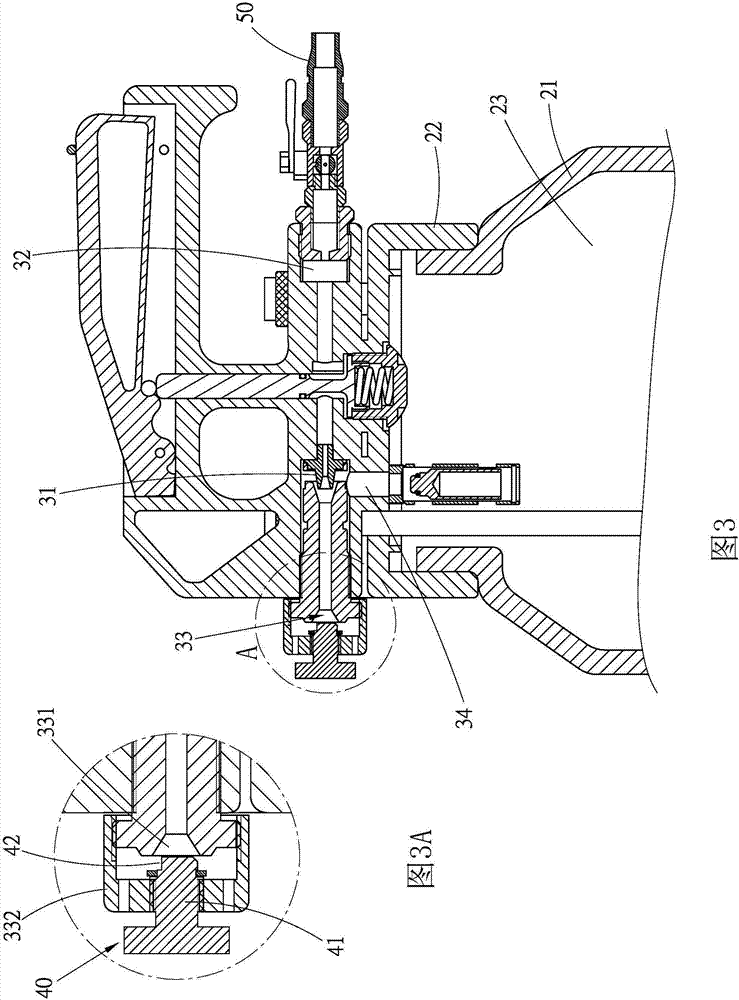

[0031] First, see Figure 1 to Figure 4 and Figure 4A As shown, the fluid pumping device 10 provided in the first preferred embodiment of the present invention with a split flow structure is the same as that disclosed in the No. 098222559 Model Patent, but the difference is that it will be disclosed in this embodiment The diversion structure of the new patent is unprecedented. Specifically, the fluid pumping device 10 with the diversion structure mainly includes a container 20, a pressure difference generating part 30, a gas blocking part 40 and an air inlet part. 50.

[0032] This container 20 has a barrel body 21 with a hollow top and a hollow top, and a barrel cover 22 that can close the top opening of the barrel body 21, so that the top opening of the barrel body 21 can be closed by the barrel cover 22, so that the barrel body 21 The inner chamber 23 is closed, and a tubular material inlet 24 communicates with the interior and exterior of the chamber 23 .

[0033] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com