Built-in Acoustic Emission Detection Method for Storage Tank Bottom Corrosion

A technology of acoustic emission detection and storage tank bottom plate, which is applied in the field of built-in acoustic emission detection of corrosion of storage tank bottom plate, can solve the problems of weak acoustic emission signal in the central area, easy to miss detection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

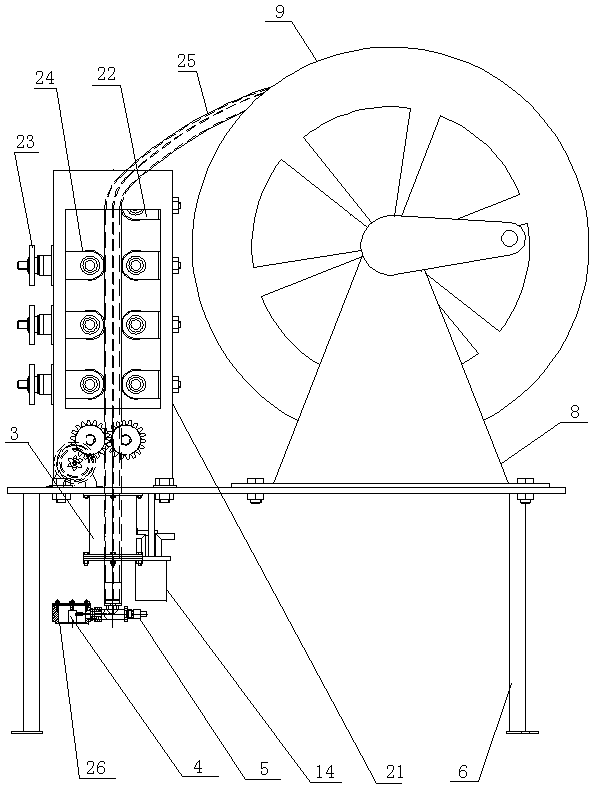

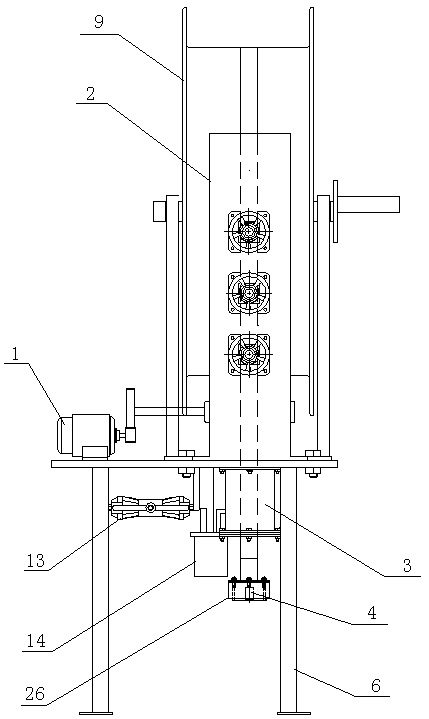

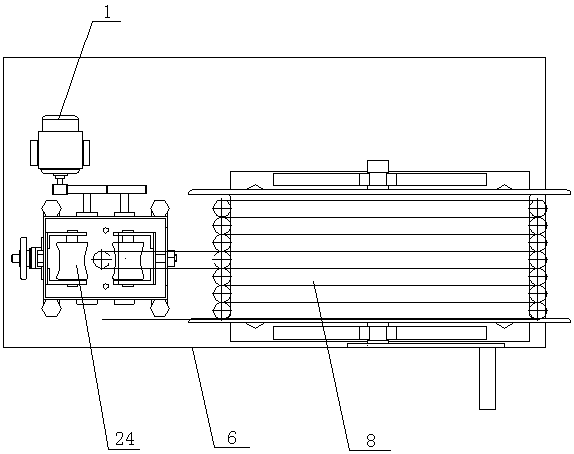

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] This storage tank bottom plate corrosion built-in acoustic emission detection method uses a built-in acoustic emission detection device to detect storage tank bottom plate corrosion, the motor 1 drives the driving roller 7 to rotate, and the acoustic emission sensor 4 and the depth gauge 5 are lowered to the bottom of the storage tank Detection, after the detection is completed, the acoustic emission sensor 4 and the depth gauge 5 are lifted out of the storage tank. combine figure 1 , figure 2 , image 3 As shown, the built-in acoustic emission detection device includes a motor 1, a wire coiler 8, a straightening machine 2, an oil removal mechanism 3, an acoustic emission sensor 4, and a depth gauge 5. The motor 1 is installed on the bracket 6, and the motor 1 selects Three-phase cage-type asynchronous motor, the motor 1 is connected to the driving roller 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com