Built-in type acoustic emission test method for corrosion of bottom plate of storage tank

An acoustic emission detection and storage tank bottom plate technology, which is applied in the field of storage tank bottom plate corrosion built-in acoustic emission detection, can solve the problems of easy missed detection and weak acoustic emission signal in the central area, and achieve convenient detection, high cleaning efficiency, and reduced labor The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

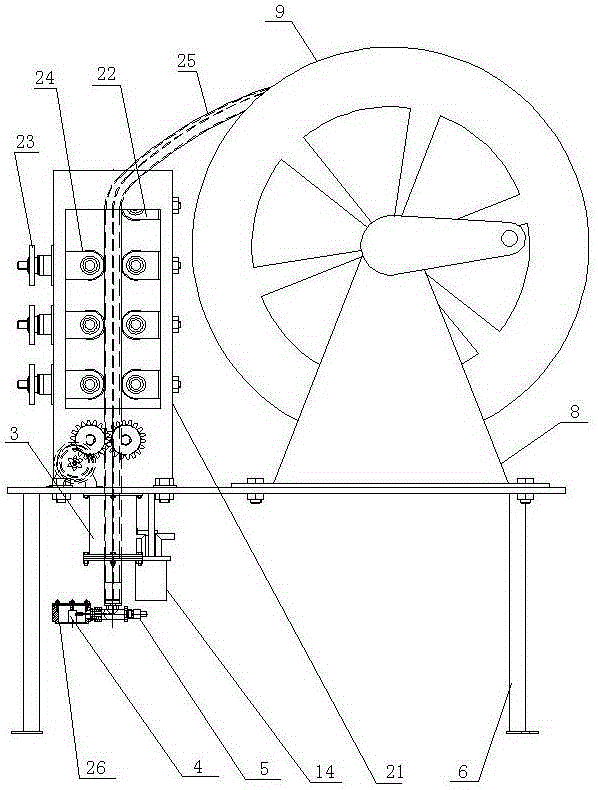

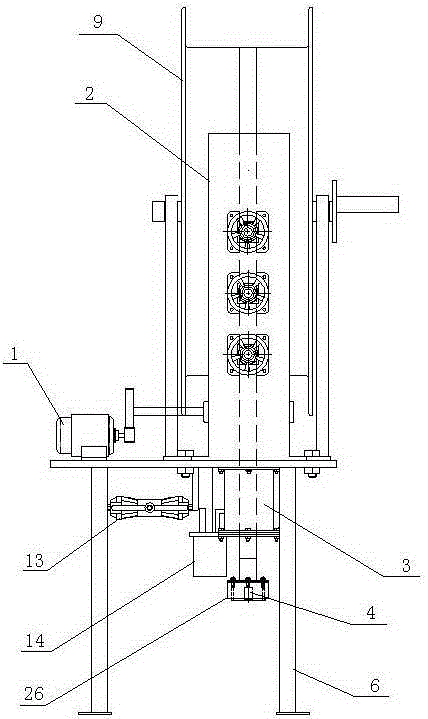

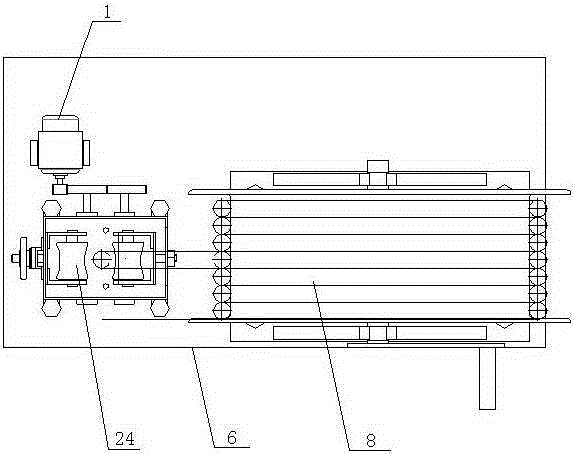

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] This storage tank bottom plate corrosion built-in acoustic emission detection method uses a built-in acoustic emission detection device to detect storage tank bottom plate corrosion, the motor 1 drives the driving roller 7 to rotate, and the acoustic emission sensor 4 and the depth gauge 5 are lowered to the bottom of the storage tank Detection, after the detection is completed, the acoustic emission sensor 4 and the depth gauge 5 are lifted out of the storage tank. to combine figure 1 , figure 2 , image 3 As shown, the built-in acoustic emission detection device includes a motor 1, a wire coiler 8, a straightening machine 2, an oil removal mechanism 3, an acoustic emission sensor 4, and a depth gauge 5. The motor 1 is installed on the bracket 6, and the motor 1 selects Three-phase cage-type asynchronous motor, the motor 1 is connected to the driving roller 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com