A precision processing equipment for pipe fittings

A precision processing and equipment technology, applied in the field of pipe fittings processing, can solve the problems of reducing the service life of bending devices, damage of pipe fittings, affecting product qualification rate, etc., and achieve the effect of simple structure and improving bending processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

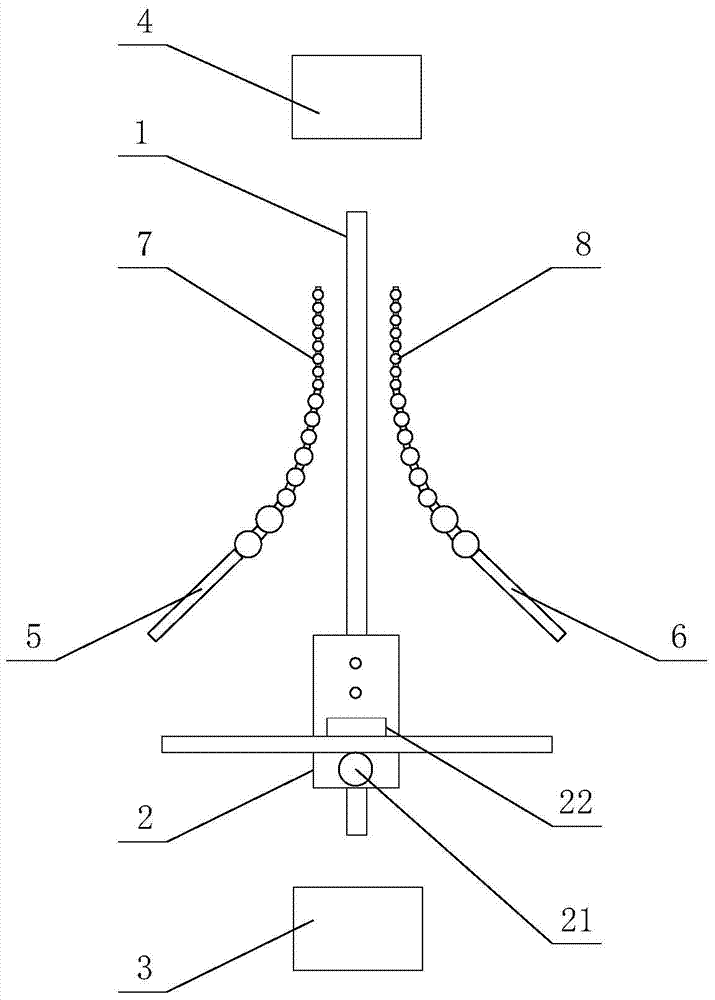

[0017] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a precision processing equipment for pipe fittings proposed by the present invention.

[0018] refer to figure 1 , a kind of precision processing equipment for pipe fittings proposed by the present invention, including: a first roller set, a second roller set, a track 1, a mounting seat 2, a driving device, a feeding device 3, a discharging device 4, a first baffle plate 5, The second baffle 6;

[0019] The feeding device 3 and the discharging device 4 are respectively located at both ends of the track 1, and the first roller group and the second roller group are respectively located at both sides of the track 1, and the first roller group includes a plurality of first extrusion rollers 7, and the first extrusion The rollers 7 are arranged along the length direction of the track 1, and the rotating shafts of a plurality of first squeeze rollers 7 are arranged in parallel and located on the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com