A method of using a cylindrical coordinate and rectangular coordinate combined arch wire bending robot

一种直角坐标、机器人的技术,应用在医药科学、牙修补术、正牙学等方向,能够解决降低正畸弓丝质量、正畸弓丝弯制机器人干涉、阻碍弯制过程等问题,达到提高弓丝弯制精度、降低弯制规划难度、提高弯制效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

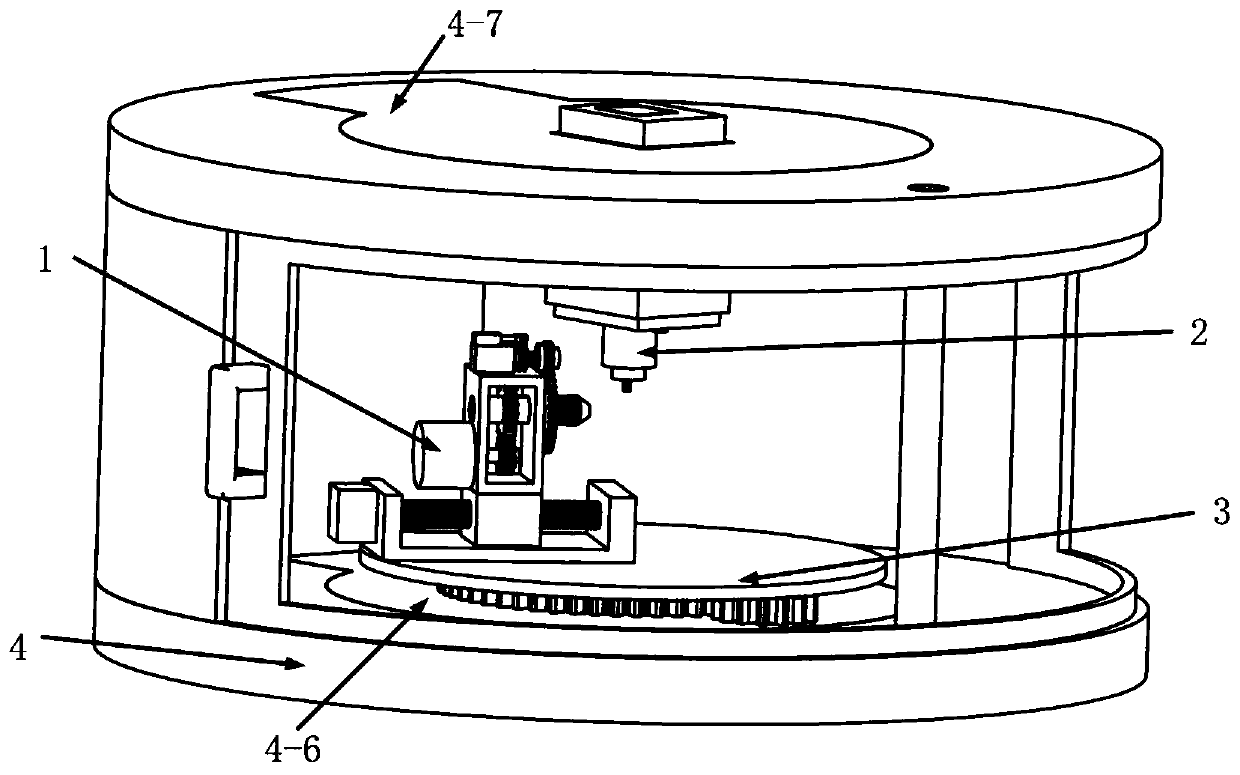

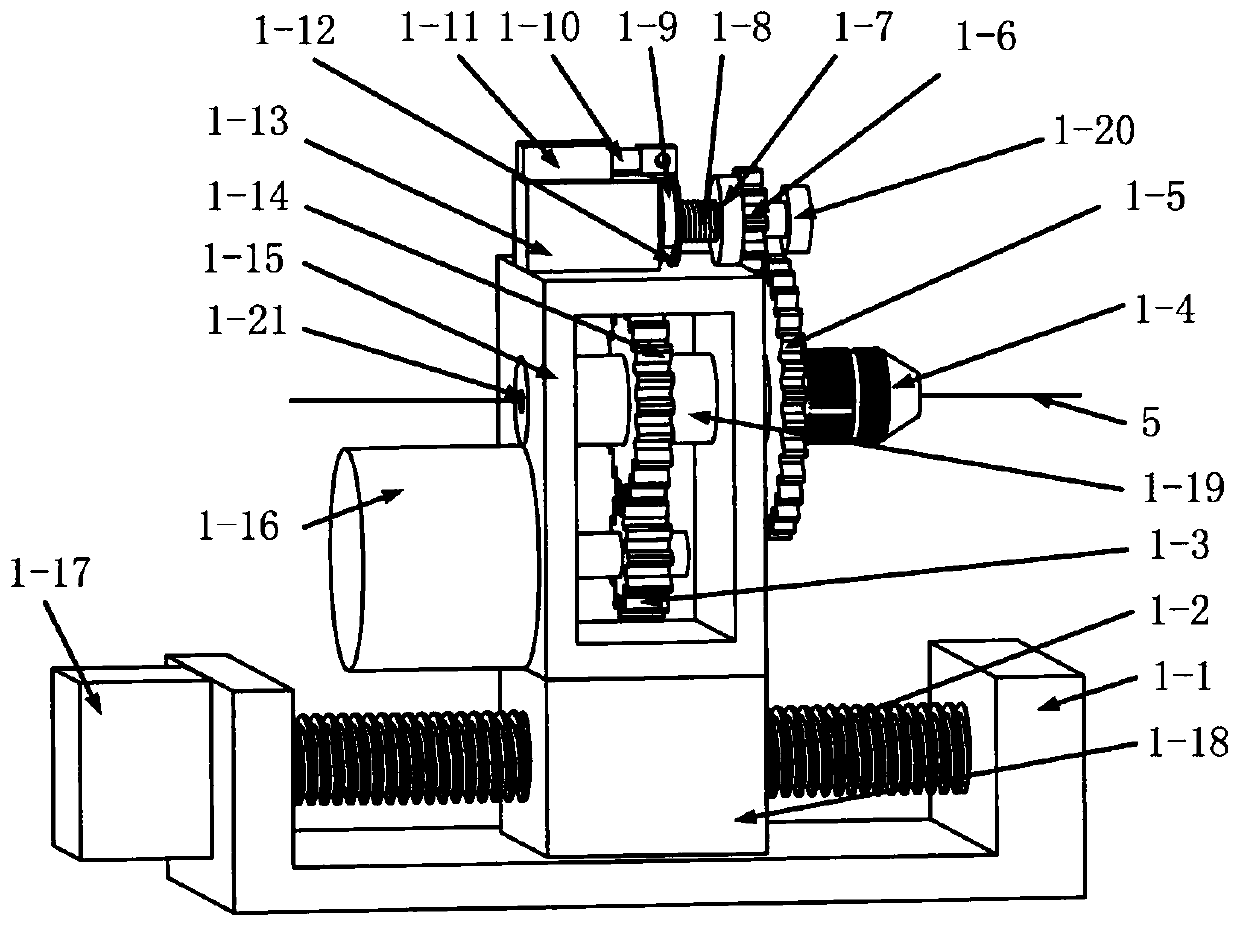

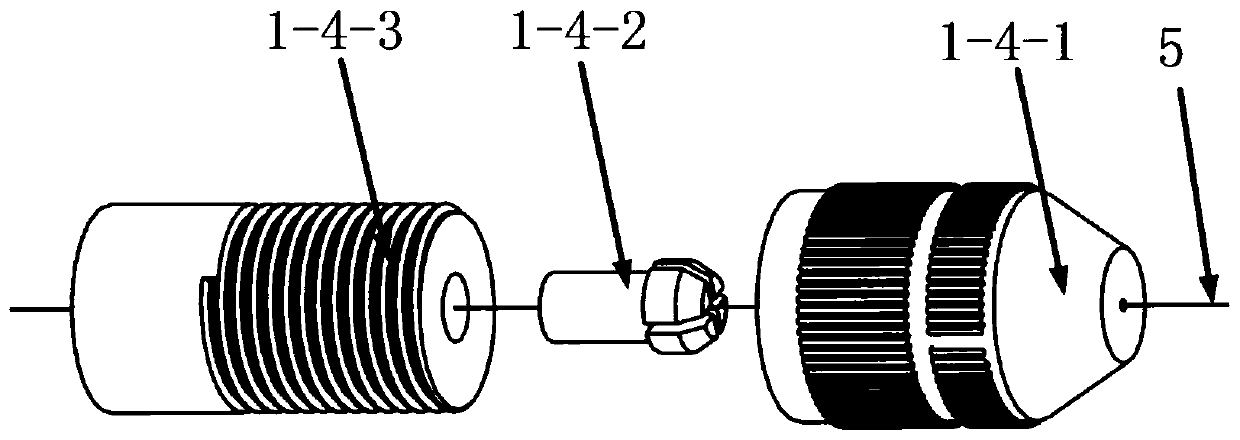

[0029] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, this embodiment adopts the following technical solutions:

[0030] The arch wire bending robot combined with cylindrical coordinates and rectangular coordinates and its use method is composed of four parts: clamp I1, clamp II2, cylindrical coordinate system turntable 3, and robot main body shell 4: clamp I in clamp I1 The lead screw guide rail slide table 1-1 is connected to the turntable 3-3 in the cylindrical coordinate system turntable 3 through bolts, and the turntable 3-3 of the cylindrical coordinate system turntable 3 is connected to the connection chassis 4-6 inside the robot main body shell 4 through bolts. Connection, clamp II 2 is fixed on the shell top 4-7 outside the main body shell 4 of the robot through bolt connection; the clamp I1 belongs to the cylindrical coordinate type, and it includes: clamp I lead screw guide rail slide 1-1...

Embodiment 2

[0036] Embodiment 2: Define the initial power-on position of the orthodontic archwire bending robot;

[0037] According to the device described in Embodiment 1, when the orthodontic archwire bending robot is in the initial power-on state, the clamp I linear motor push rod 1-11 in the clamp I1 is in the initial state of not being pushed out, and the clamp I clamps the motor 1-13. Clamp I rotary motor 1-16 and clamp I lead screw motor 1-17 are in the standby state, and the distance between clamp I lead screw nut 1-18 and clamp I lead screw motor 1-17 is the clamp Ⅰ The initial position of the screw nut 1-18, the pincer Ⅰ clamps the driven gear 1-5 and the pincer Ⅰ clamps the driving gear 1-6 is in a non-meshing state, and the pincer I clamps the chuck core in the tapered chuck 1-4 1-4-2 is in the non-clamping state; the linear motor 2-5 in the clamp II 2, the screw motor 2-9 in the clamp II and the rotary motor 2-12 in the clamp II are all in the standby state, and the screw nut...

Embodiment 3

[0038] Embodiment 3: The specific implementation of the orthodontic archwire robot to complete the automatic wire feeding task;

[0039] According to the device described in Example 1, when the dental wire bending technician needs the orthodontic archwire robot to complete the automatic wire feeding task, the specific implementation method is: before the wire feeding task is performed, the orthodontic archwire robot is in the initial power-on state, The clamp I linear motor push rod 1-11 in the clamp I1 is still in the initial state that has not been pushed out, the clamp I clamping motor 1-13, and the clamp I rotating motor 1-16 are still in the initial state and remain in the standby state, and the clamp I clamps The passive gear 1-5 is in a non-meshing state with the pincer Ⅰ clamping the driving gear 1-6, and the collet core 1-4-2 in the pliers Ⅰ tapered chuck 1-4 is in a non-clamping state. When dental wire bending The technician sends the orthodontic archwire 5 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com