Automatic carrying equipment and rotary suction device thereof

A suction device, rotary technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of large manpower and material resources, time-consuming and laborious, and high production costs, and achieves strong practicability, buffer protection and absorption, degree of automation and reliability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

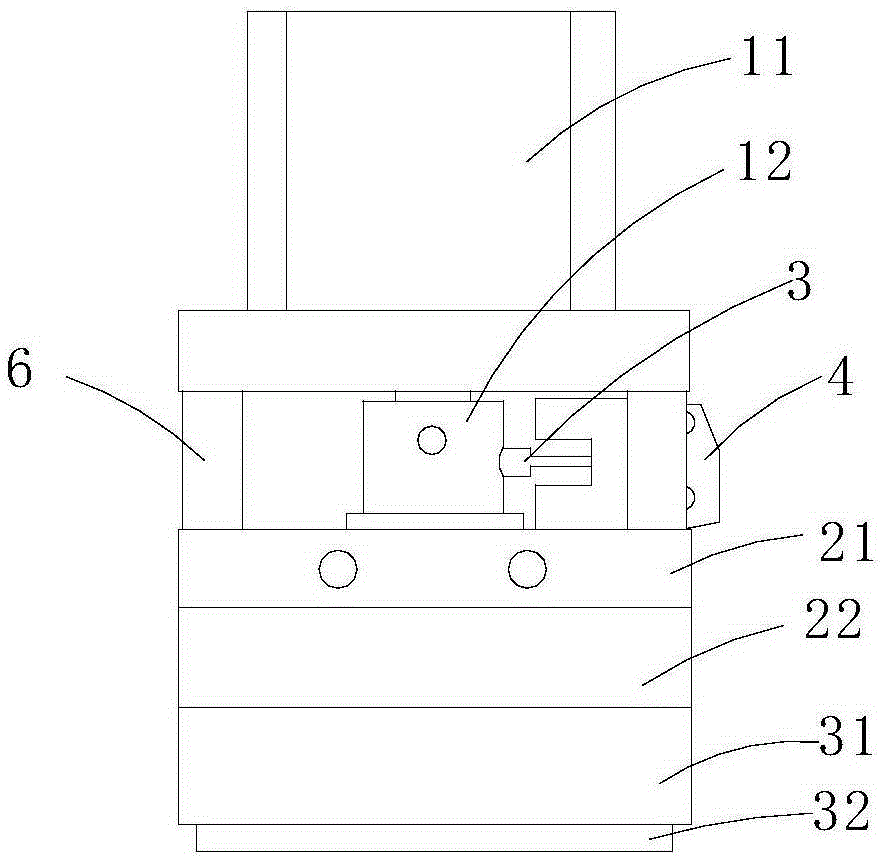

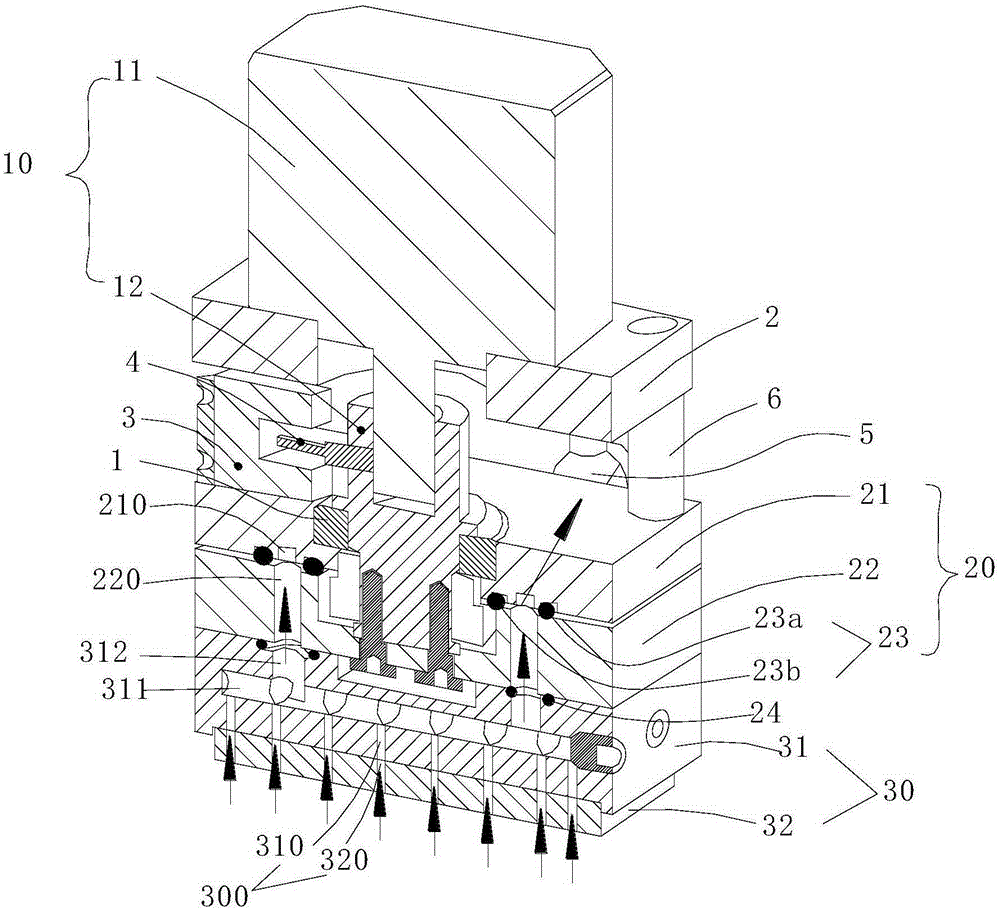

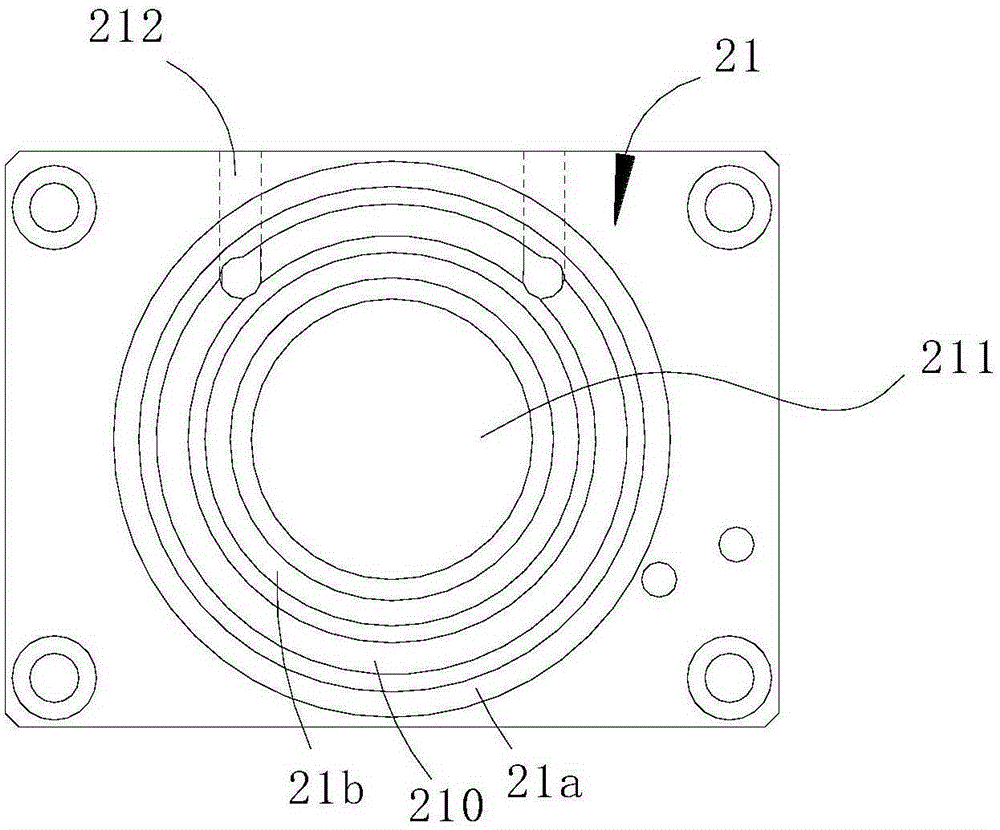

[0026] refer to figure 1 and figure 2 , the rotary suction device of the present invention mainly includes a drive assembly 10, an air collection and flow guide assembly 20, and a vacuum chuck assembly 30, wherein the drive assembly 10 includes a motor 11 and a drive shaft 12 connected to the shaft of the motor 11; A hollow diversion channel is provided inside the component 20, and one end of the diversion channel is used to connect a vacuum generating device; a plurality of suction holes 300 are provided on the end surface of the vacuum chuck component 30, and the suction holes 300 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com