hot guts

A heat tank and partition technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of dripping water from the faucet and unable to discharge hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

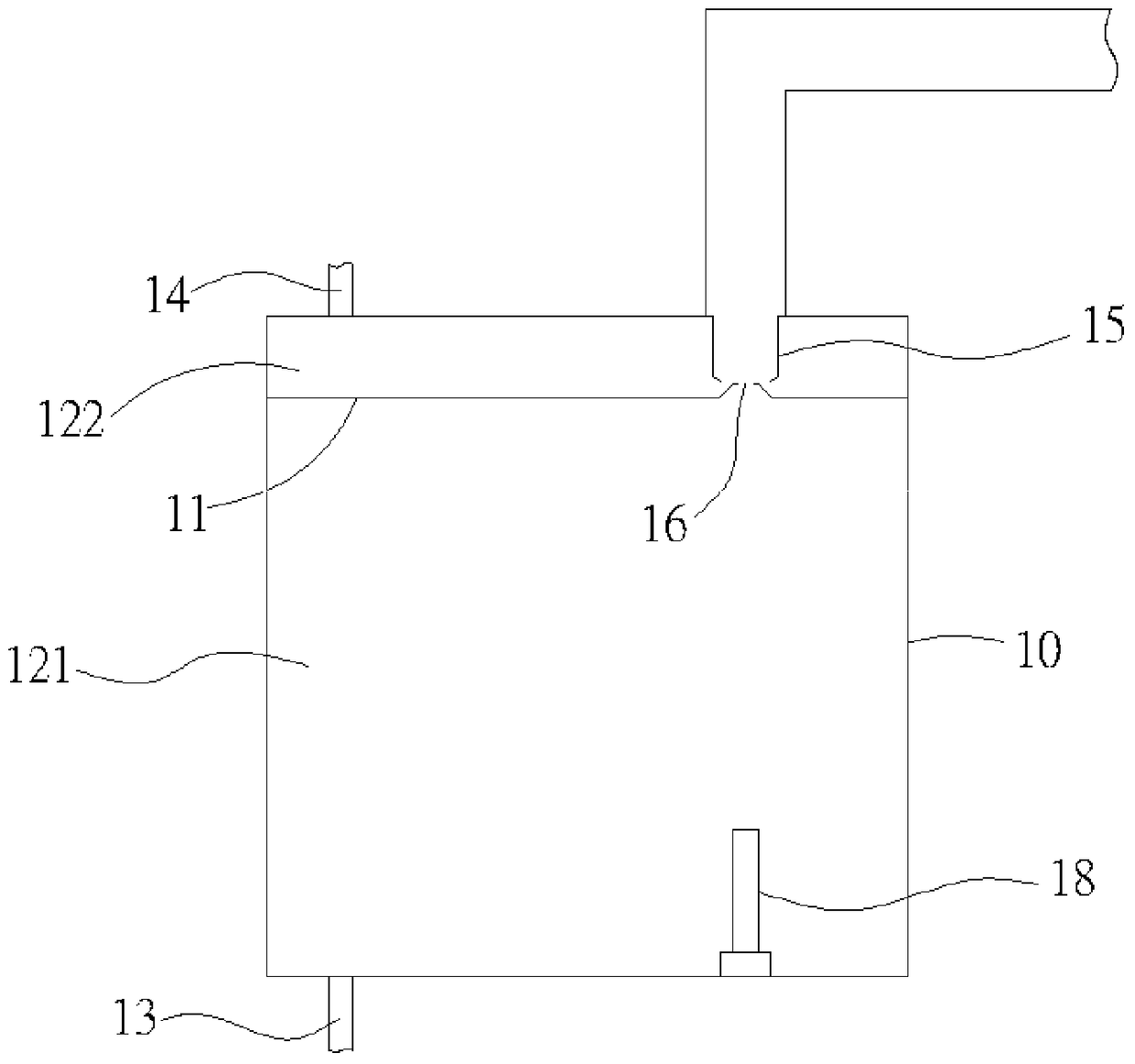

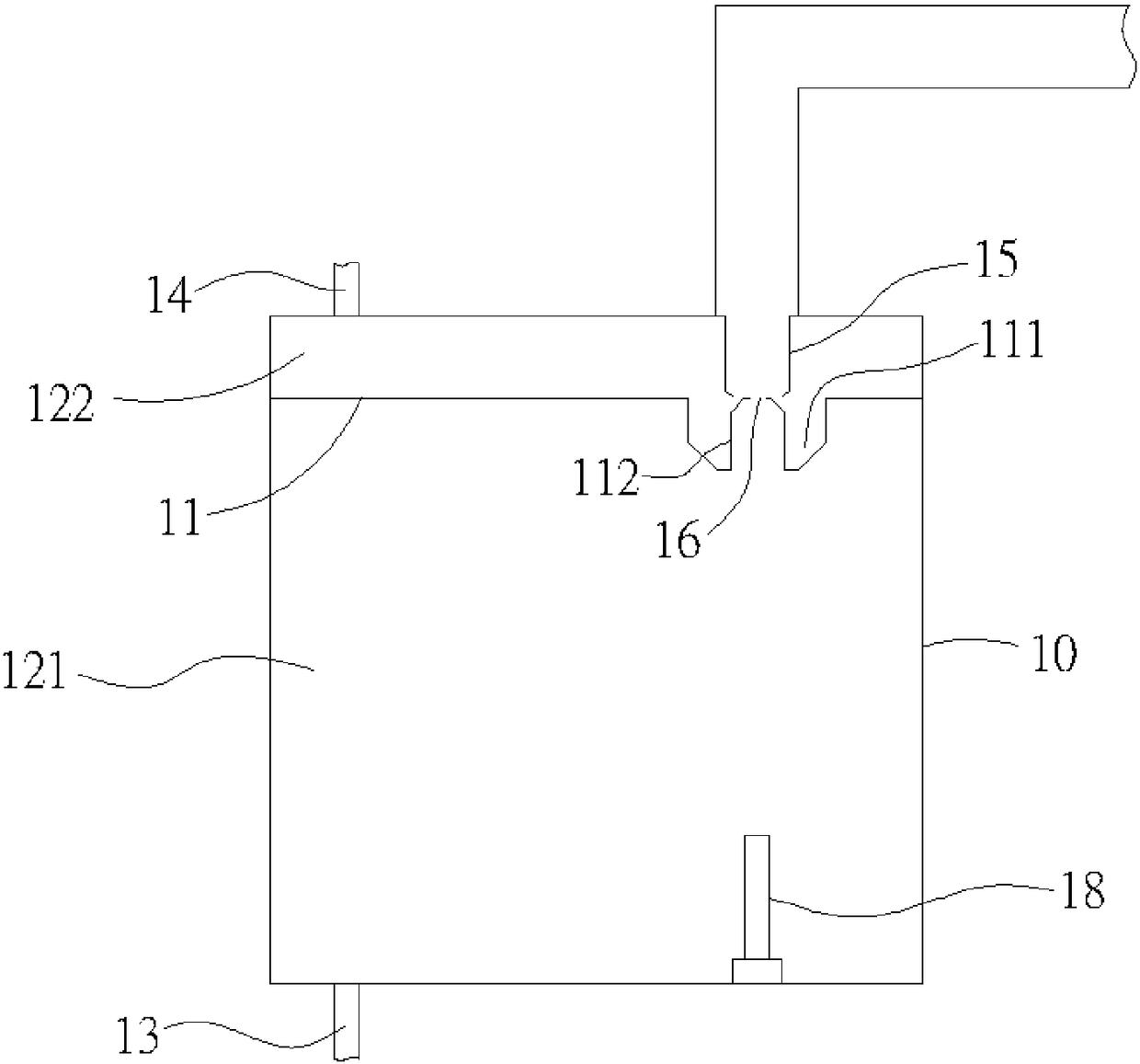

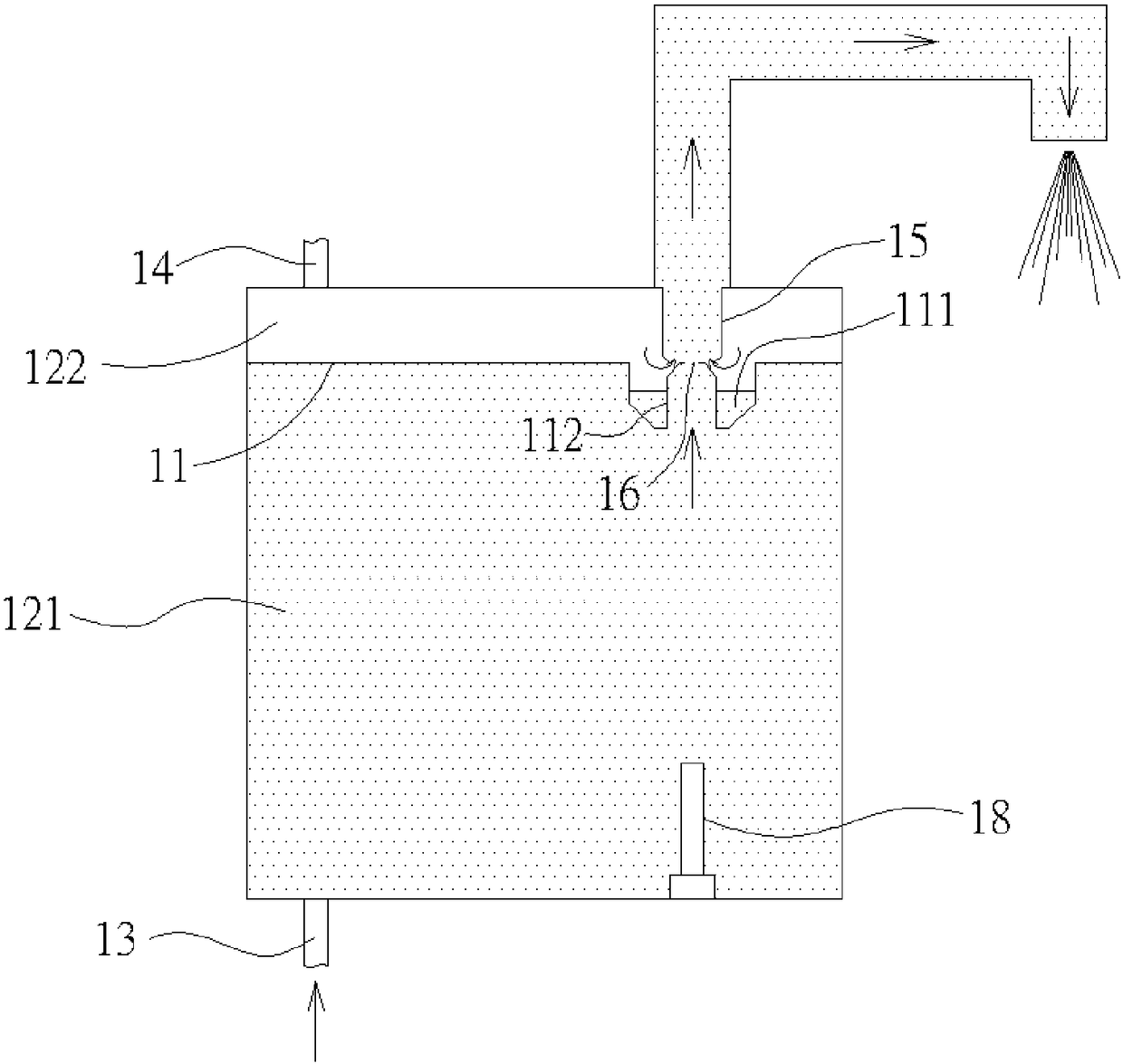

[0039] The invention mainly provides a hot water supply device that can return the hot water in the water outlet pipe to the heat tank after the water outlet action is completed, effectively reducing the residual amount of hot water in the water outlet pipe, and avoiding the hot water remaining after the water outlet action is completed. There is a thermal tank structure in which hot water is continuously squeezed out, such as figure 1 As shown in the cross-sectional view of the thermal tank structure according to the first embodiment of the present invention, the thermal tank 10 of the present invention is provided with a partition 11 inside.

[0040] The partition 11 divides the entire inner space into a first chamber 121 located at the bottom and a second chamber 122 located at the top. A chamber 121 and the first chamber 121 are arranged below the heat tank 10 . The water inlet 13 communicated, the top of the heat tank 10 is provided with an air hole 14 communicating with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com