Flexible direct-current converter valve and bridge arm damping module energy taking circuit thereof

A flexible DC and converter valve technology, applied in the direction of electrical components, output power conversion devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Embodiment of bridge arm damping module energy harvesting circuit

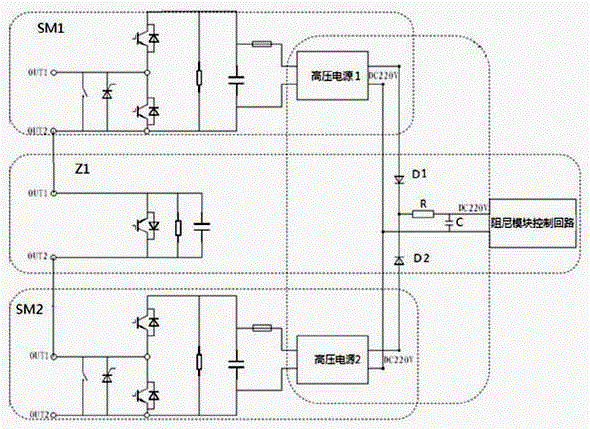

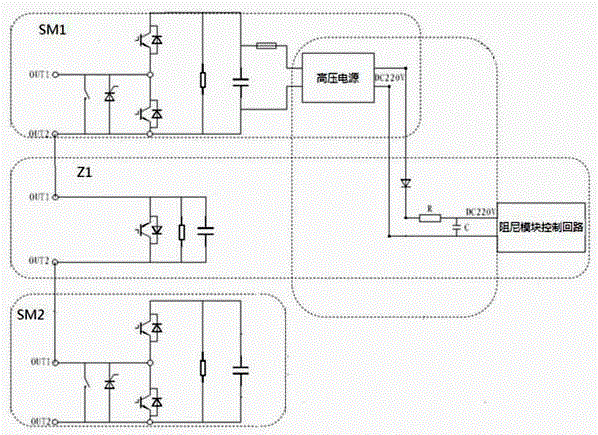

[0019] Such as figure 1 The energy-taking circuit of the bridge arm damping module of the flexible DC converter valve, the bridge arm damping module Z1 obtains electric energy through its two adjacent sub-modules SM1 and SM2. How to avoid the interaction between the bridge arm damping module and the power supply sub-module at the time of failure is a difficult problem that limits the development of this technology by providing electric energy to it through adjacent sub-modules.

[0020] The circuit includes: high-voltage isolated power supply (that is, high-voltage power supply 1 and high-voltage capacitor 2 shown in the figure), blocking diodes D1 and D2, current-limiting resistor R and voltage support capacitor C. The high-voltage isolated power supply input is connected to the DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com