A maintenance method for oil-lubricated shaft coupling

An oil-lubricated coupling technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problem that the oil-lubricated coupling cannot be maintained and inspected, and the operation of the oil-lubricated coupling is not correct. Problems such as standardization and spare parts that have not reached their service life have achieved the effect of improving the post-maintenance market, saving learning costs, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

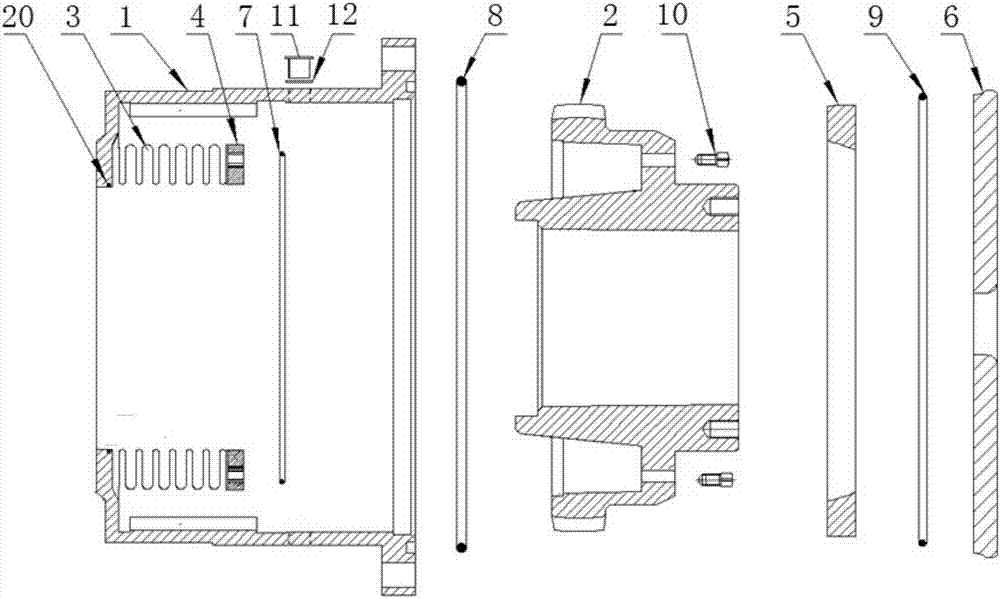

[0055] This embodiment provides a maintenance method using oil-lubricated couplings for inspection and maintenance of KWD170 couplings. A KWD170 coupling has been split into two half-couplings before entering the factory for inspection and maintenance. The customer will After the coupling is removed from the main shaft end of the motor, remove the twisted hole bolts of the coupling, split the whole (one) coupling into two half-couplings, and finally send the two half-couplings to the factory for maintenance .

[0056] After the half coupling enters the factory, its inspection and maintenance process is as follows:

[0057] (1) Registration at the factory: take photos and register the semi-couplings to be repaired and tested;

[0058] (2) Preliminary cleaning: Put the half coupling into SD-400 industrial degreasing cleaning agent, soak it at 25°C for 2 hours, then clean the coupling, and dry the coupling with a high-pressure air gun after cleaning;

[0059] (3) Information re...

Embodiment 2

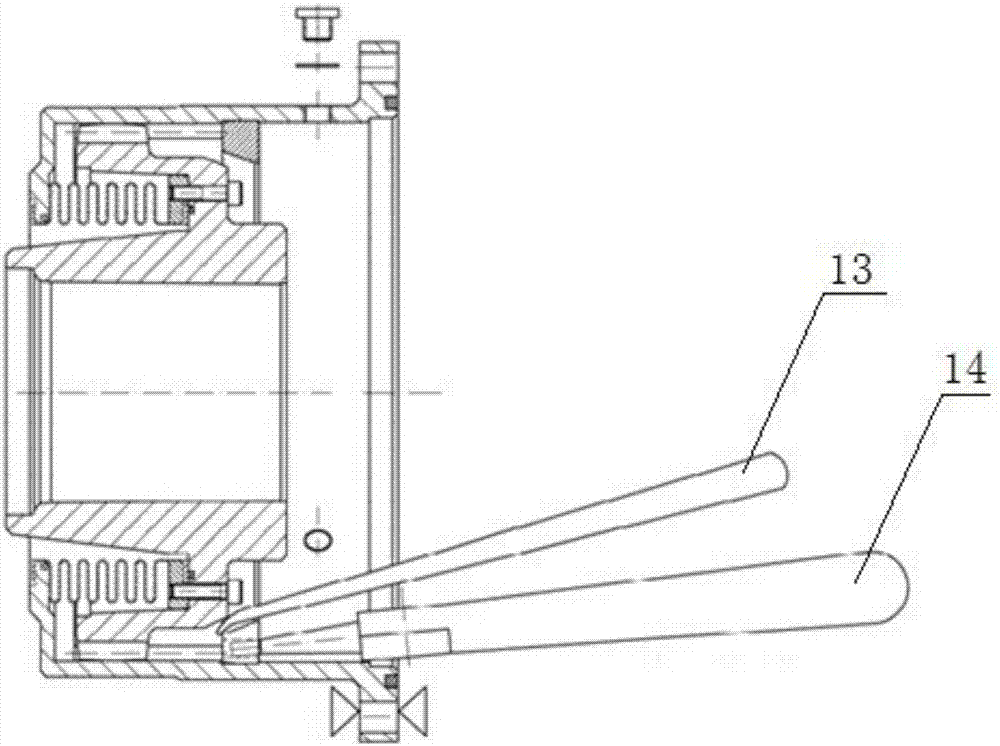

[0112] This embodiment provides a maintenance method using an oil-lubricated coupling to detect and maintain the KWD170 coupling. stick like Figure 4 As shown, the crowbar is a long rod with an arc-shaped sharp hook at one end of the long rod. When removing the stop ring, use the arc-shaped sharp hook at the front end of the crowbar to insert into the gap around the stop ring. stick and use the ring pliers to slightly lift the stop ring with the help of the hole, such as image 3 shown.

Embodiment 3

[0114] This embodiment provides a maintenance method using an oil-lubricated coupling to detect and maintain the KWD170 coupling. The maintenance steps are as described in Example 1, and the difference is that in step (6), bellows are used for cleaning The roller cleans the bellows, and the structure of the bellows cleaning roller is as follows: Figure 8 As shown, the bellows cleaning roller includes an L-shaped rod, and an S-shaped corrugated rod is arranged at one end of the L-shaped rod. When in use, the S-shaped corrugated rod is covered with gauze and inserted into the gap of the corrugated pipe, and the worker holds the L-shaped rod to wipe the oil in the corrugated pipe back and forth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com