A Maintenance Method of Grease Lubricated Coupling

A coupling and grease lubrication technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problem that the sealing performance is not as high as that of oil-lubricated couplings, grease-lubricated couplings The problem of not being able to maintain inspection and parts that are not yet available for service life can improve the post-maintenance market, save learning costs, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A maintenance method for a grease-lubricated shaft coupling, using the maintenance method to detect and maintain an ESCO shaft coupling, the steps are as follows:

[0056] (1) Registration at the factory: take photos and register the ESCO half-couplings to be repaired and tested, and record the number and mark of the half-couplings to prevent confusion;

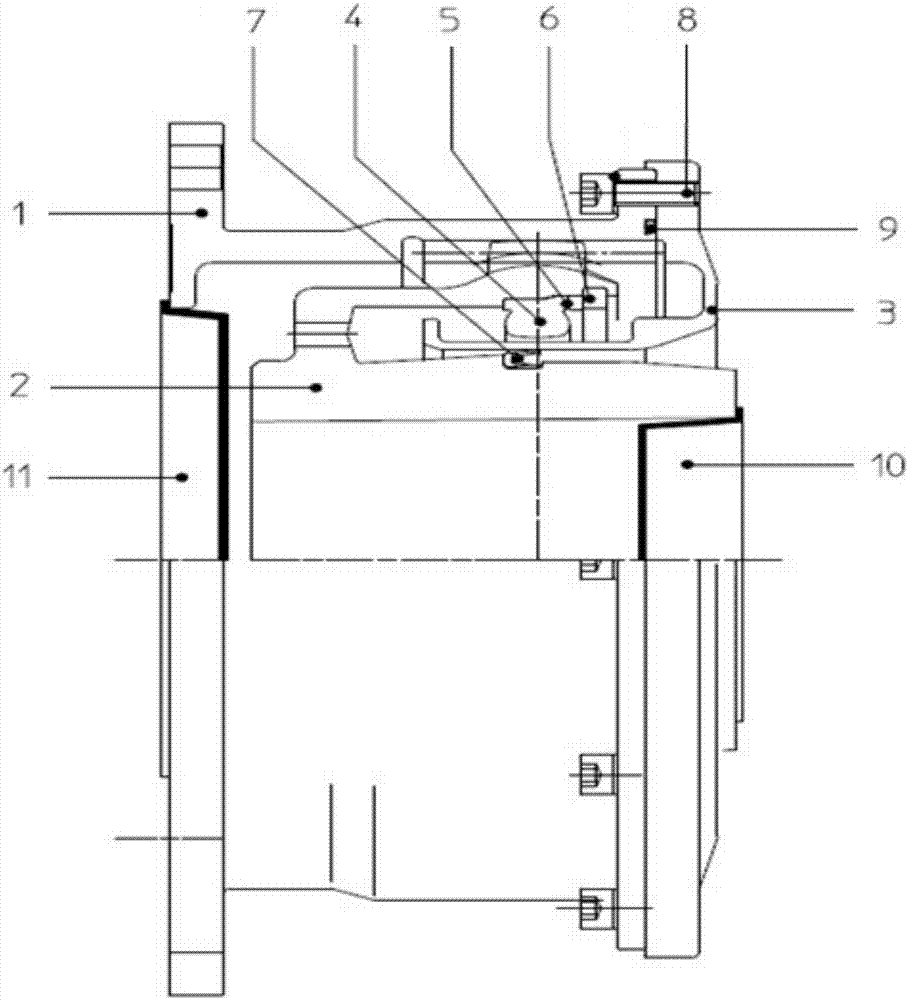

[0057] (2) Disassembly: Remove the components on the ESCO half coupling, first remove the end cover bolts and end cover bolt washers, then remove the end cover, and then remove the end cover together with the outer gear hub from the inner gear cylinder, Then remove the spring retaining ring from the outer gear hub, then pull out the outer gear hub from the end cover, remove the thrust washer and thrust ring, and finally remove the O-ring from the outer gear hub;

[0058] Perform the same inspection on the inner gear cylinder, outer gear hub, end cover, thrust ring, thrust washer, gasket, energy storage sealing ring, an...

Embodiment 2

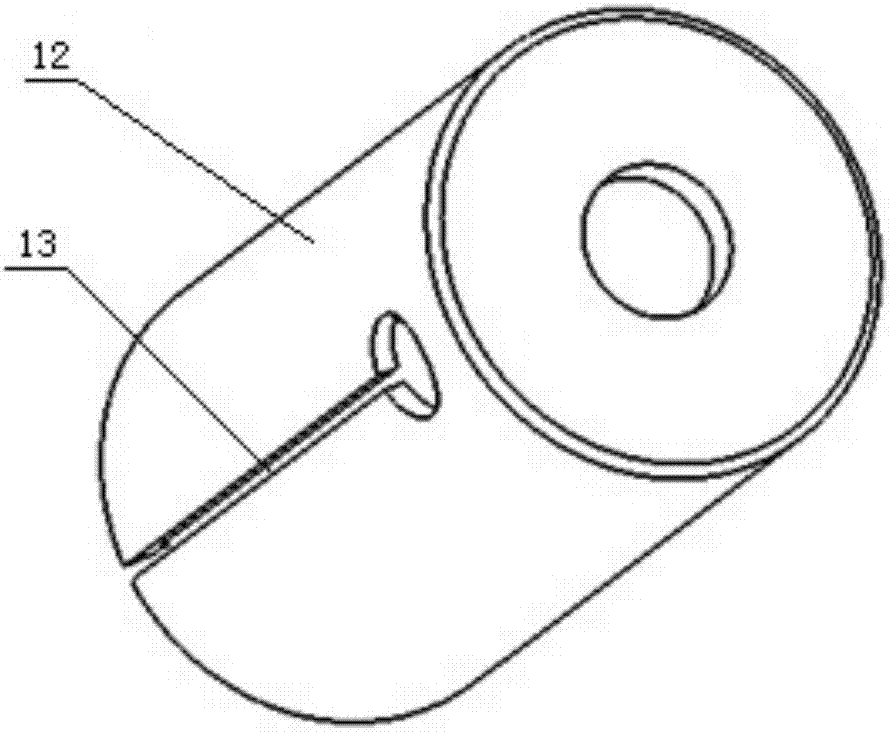

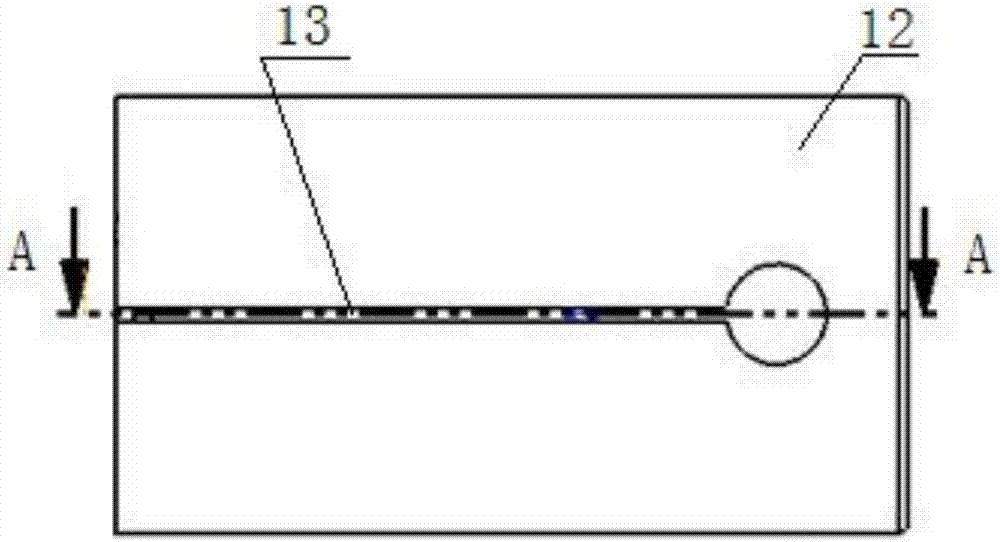

[0082] A maintenance method using a grease-lubricated coupling to detect and maintain ESCO couplings, the maintenance steps are as described in Example 1, the difference is that the energy storage sealing ring is ring-sleeved on the outer gear hub by using a press-fitting tool Above, wherein, the pressing tool includes an inner sleeve and an outer sleeve nested inside and outside, the inner sleeve includes a conical upper part and a lower cylindrical body connected as one, and a stepped hollow is arranged in the inner sleeve. The upper end of the circular frustum has a through hole connecting the cavity; the outer sleeve is a hollow cylinder, and three long slits are evenly distributed on the side wall of the hollow cylinder, and the top of the long slit is provided with Arc. The specific structure of the pressing tool is as follows: Figure 2a to Figure 4 shown.

[0083] When in use, the "lip" of the energy storage sealing ring faces upward, so that the stepped cavity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com