Crawler-type chassis for agricultural machine

A crawler and crawler technology, applied in the field of supporting chassis, can solve problems such as difficulties, insecurity, troubles, etc., and achieve the effect of prolonging the service life and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

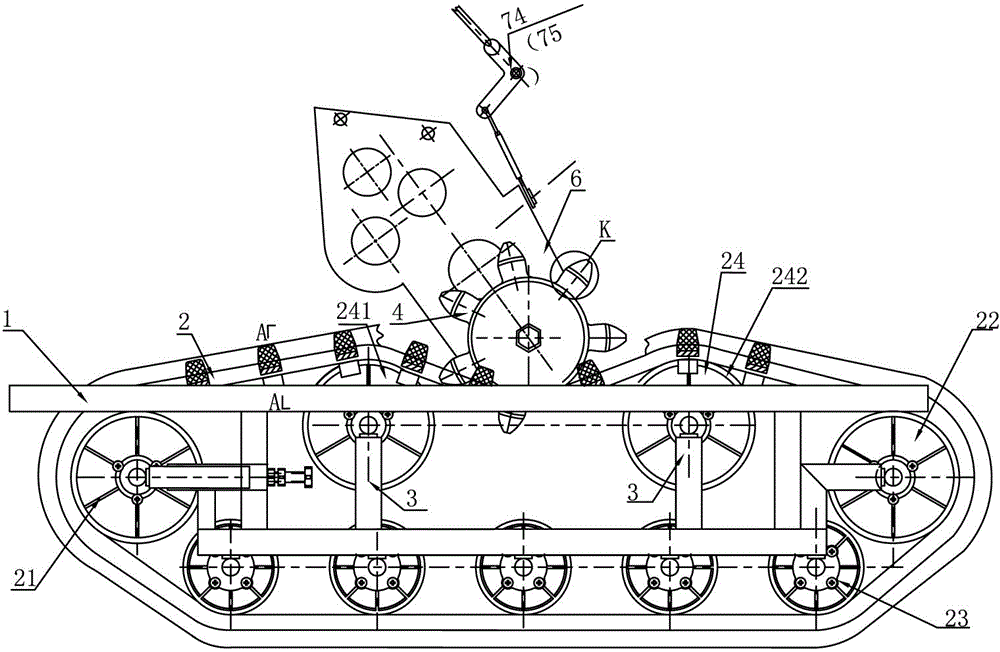

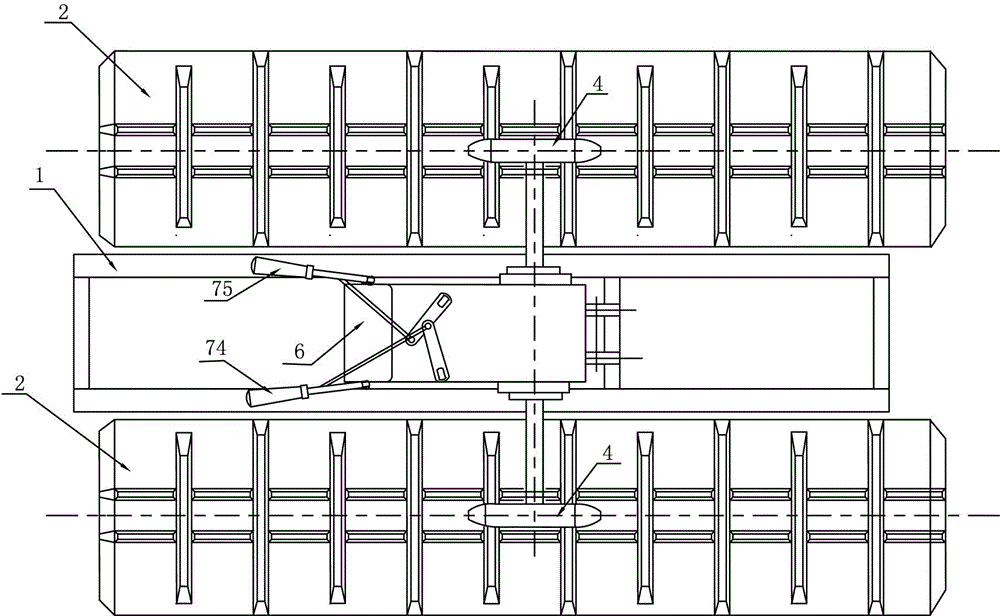

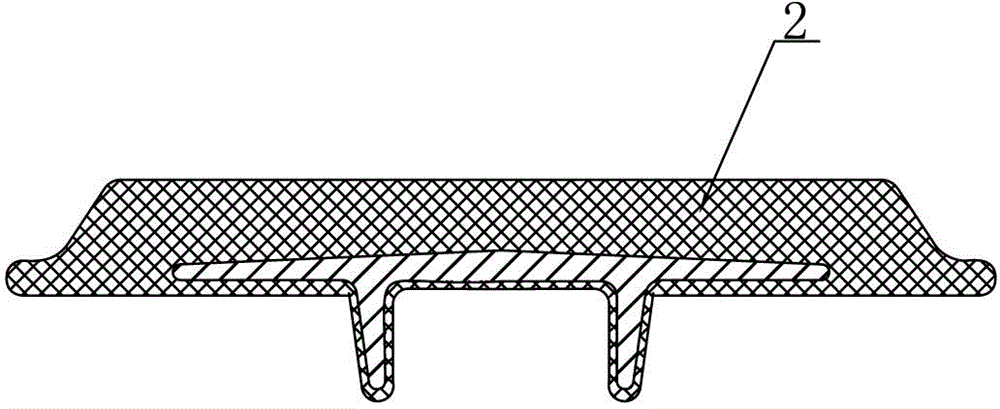

[0035] Such as Figure 1-Figure 10 As shown, a crawler chassis for agricultural machinery of the present invention includes a chassis frame 1, one side of the chassis frame 1 is connected to the left annular crawler structure, and the other side is connected to the right annular crawler structure, and the left and right annular crawler structures It is arranged symmetrically, and the left and right endless track structures respectively include an endless track 2 . The endless crawler belt 2 is provided with a driven wheel set consisting of a front pulley 21, a rear pulley 22, a bottom pulley 23 and a top pulley 24, wherein the top pulley 24 is a front top pulley 241 and a rear top pulley 242. , and the front and rear top pulleys 241, 242 are located at the inner top of the endless track 2 and hold the endless track 2 upwards, and a driving wheel 4 is engaged with the outer top of the endless track 2, and the driving wheel 4 is located at the top of the front and rear top belts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com