Fixing column device with cooling fan for PCB

A technology of PCB circuit board and heat dissipation fan, which is applied in the field of fixed column devices with heat dissipation fans, and can solve problems such as damage to fixing nails, affecting equipment use and maintenance, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

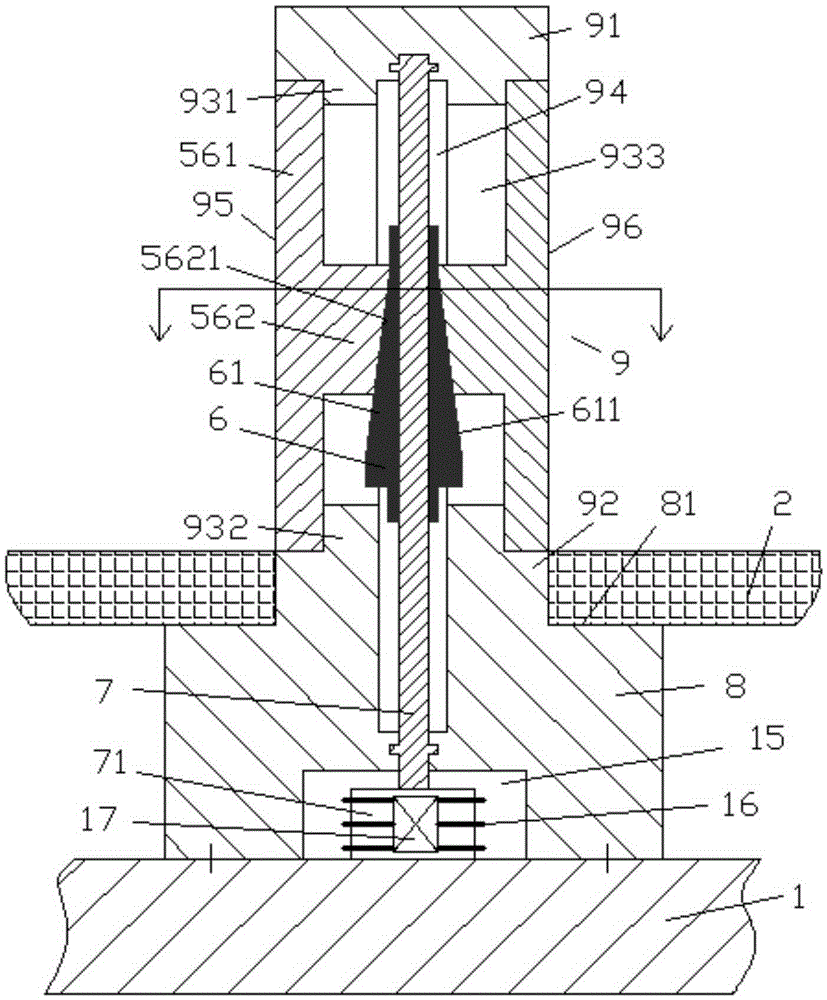

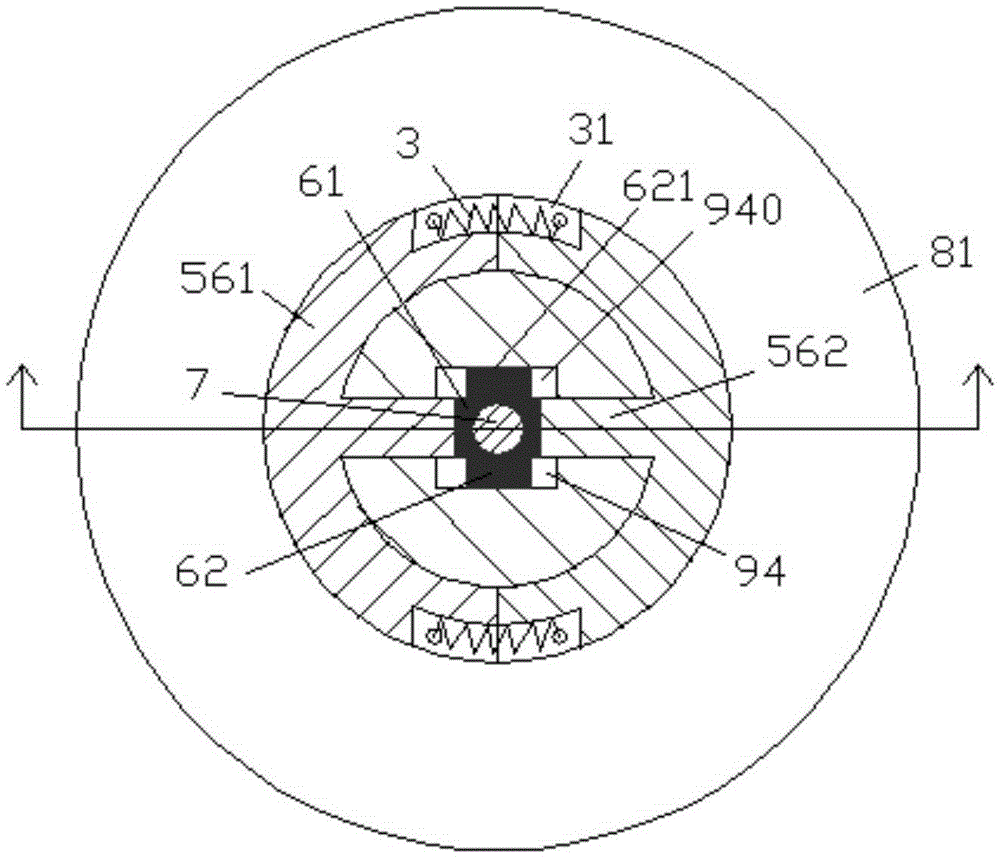

[0011] Combine below Figure 1-2 , the present invention will be described in detail.

[0012] According to an embodiment, a fixed column device with a heat dissipation fan for a PCB circuit board is used to be fixedly connected with the frame body 1 so as to fix the PCB circuit board 2 on the frame body 1, and the fixed column device includes a bottom The fixed body 8 fixedly connected with the frame body 1, the fixed body 8 includes a bottom shoulder portion having a shoulder surface 81 for carrying the back of the PCB circuit board and an integrally formed shoulder surface 81 perpendicular to the Vertical post part 9, said vertical post part 9 comprises the cylindrical root part 92 integrally connected with said shoulder surface 81 of the bottom and used for engaging with the fixing hole on the PCB circuit board, the cylindrical top part 91 at the top end and the intermediary A generally cylindrical intermediate connecting portion between the cylindrical root 92 and the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com