Operation position detection device

A technology for operating position and detection devices, applied in electromagnetic measuring devices, electric/magnetic solid deformation measurement, instruments, etc., can solve problems such as design limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

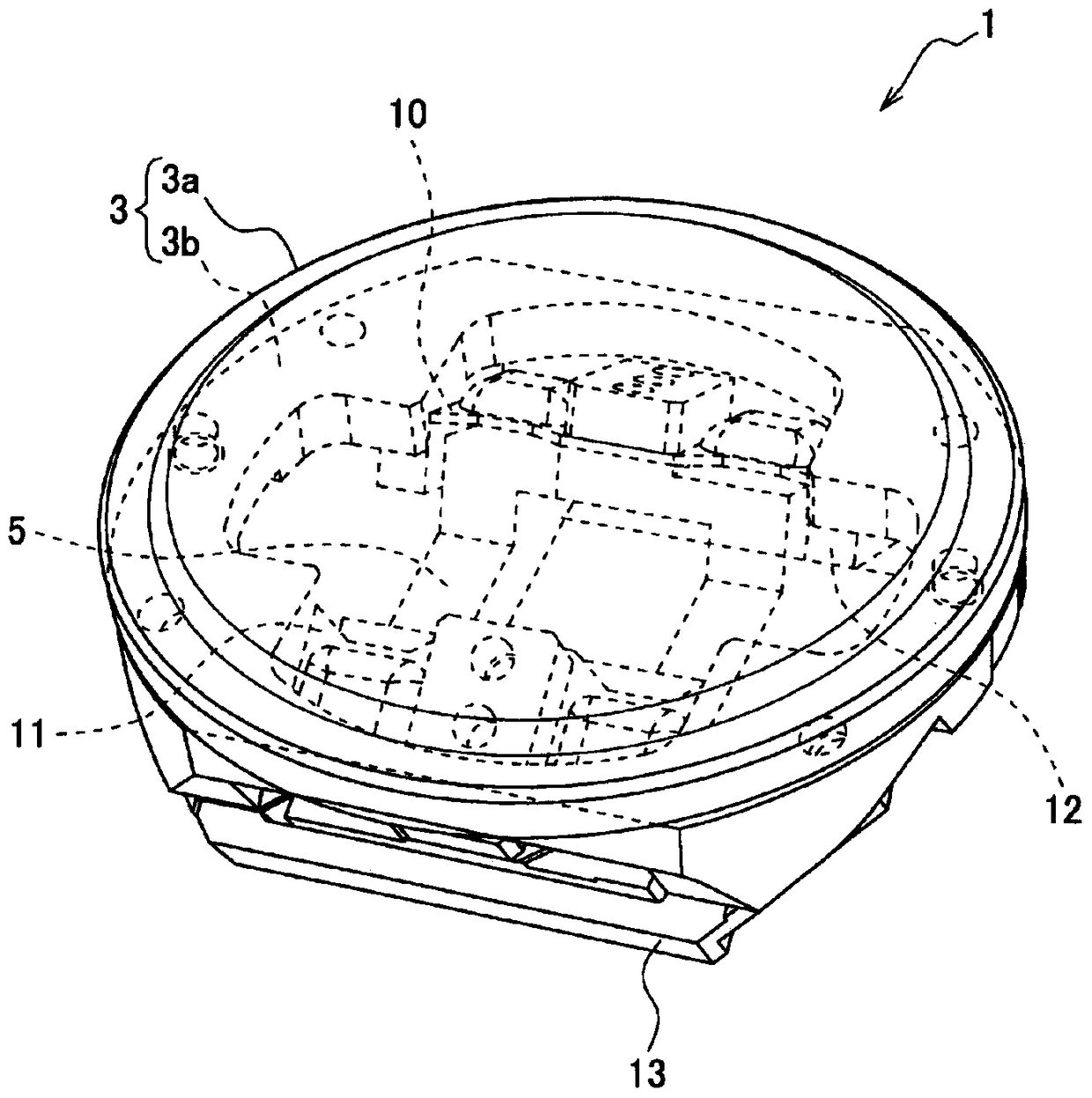

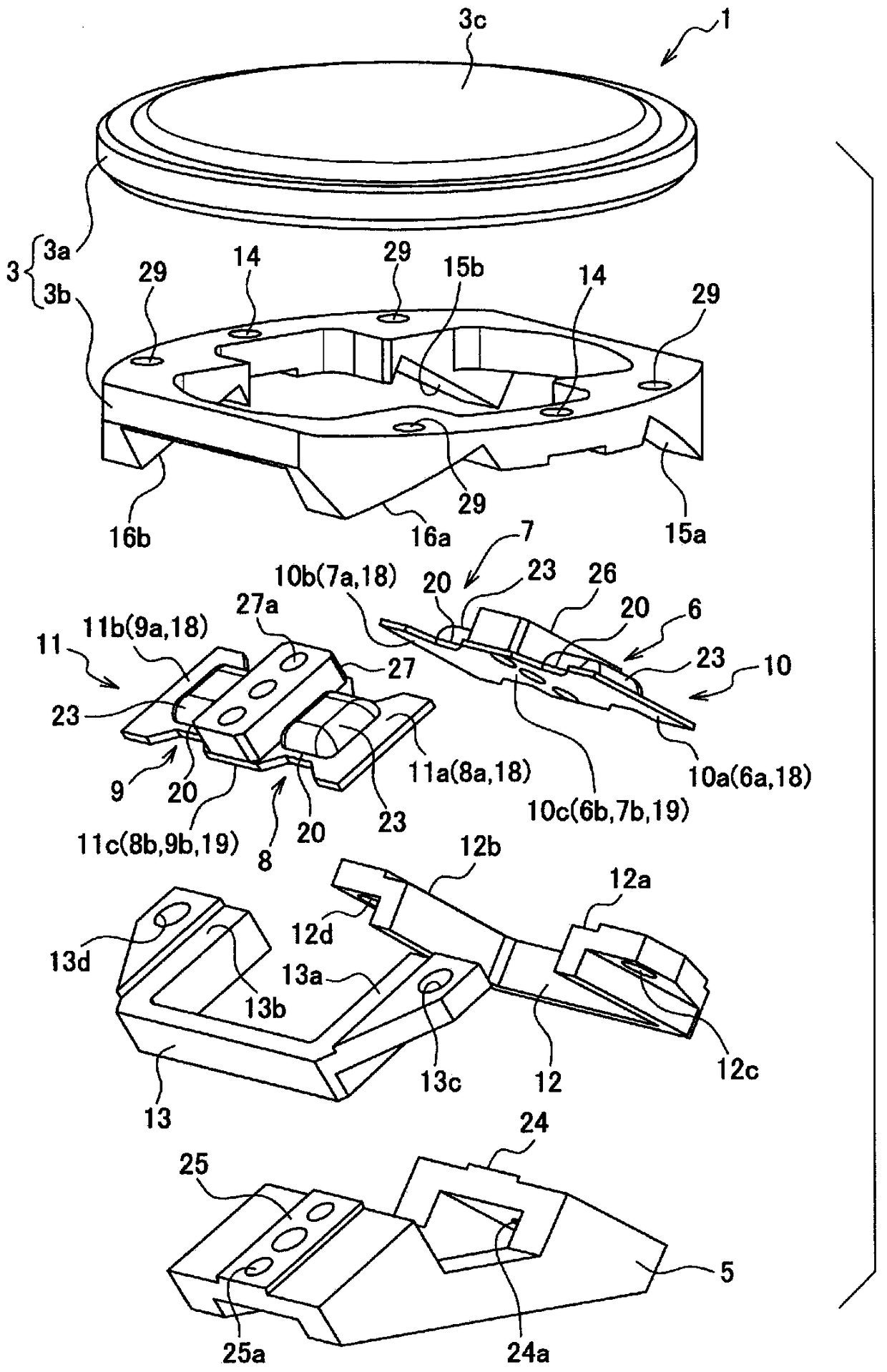

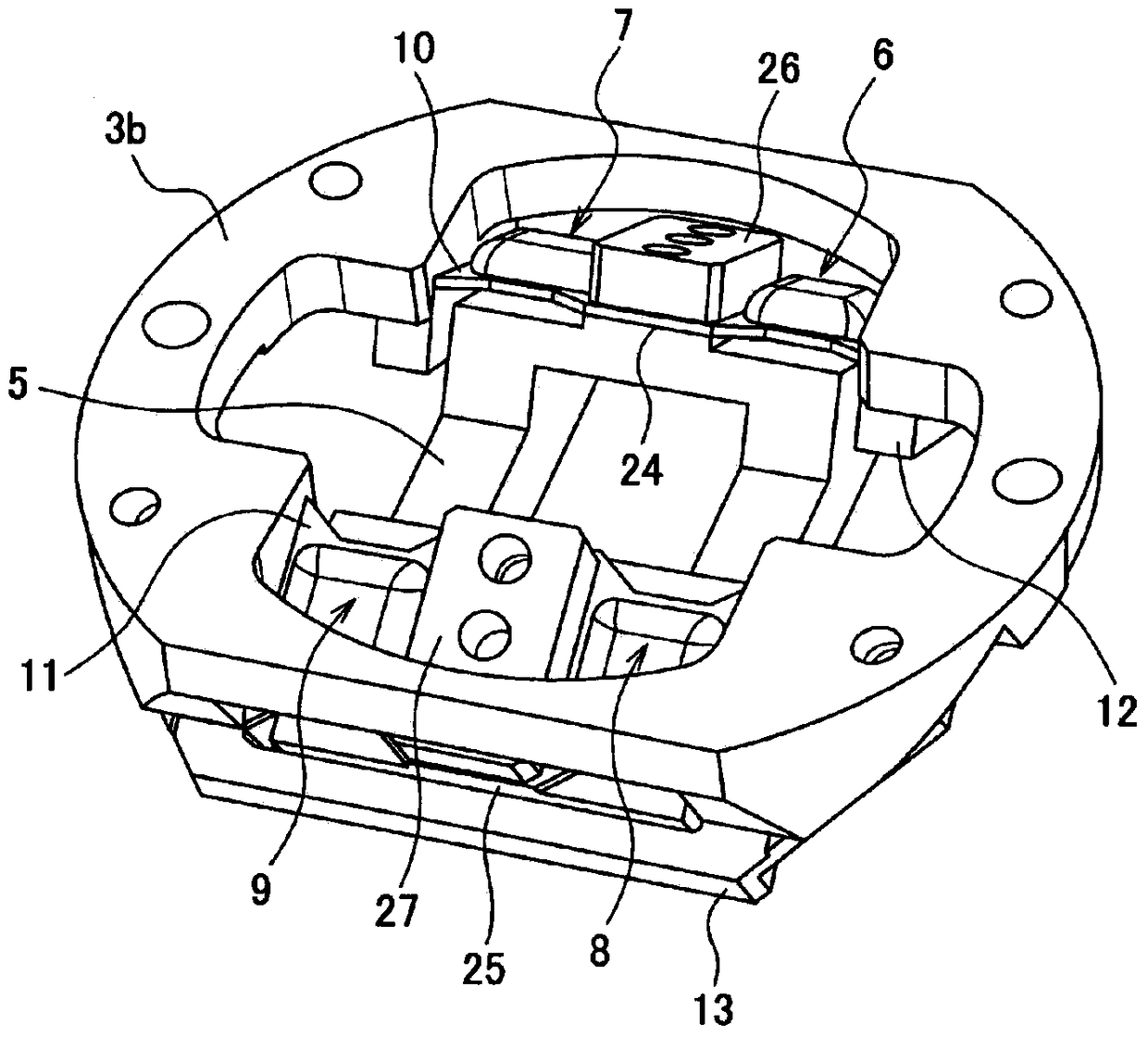

[0040] like Figure 1 to Figure 7 As shown, the operation position detection device 1 of the first embodiment includes: an operation body 3, a base member 5 serving as a base of the device 1, a flat member 10 forming two flat detection bodies 6, 7, and a flat body. The plate members 11 of the two detection bodies 8 and 9 and the pressing members 12 and 13 for connecting the plate members 10 and 11 to the operating body 3 .

[0041] The operating body 3 is composed of a plate-shaped (disk-shaped in this example) operating member 3 a and a substantially cylindrical frame member 3 b. In addition, in the following description, with respect to the up-down direction of the operation position detection device 1 , the side of the operation member 3 a is up, and the side of the base member 5 is down.

[0042] The operation member 3a is attached to the upper side end surface of the frame member 3b via the screw hole 14 provided in the frame member 3b, for example. The circular upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com