A rotatable high-pressure closed-type fine water mist spray gun

A rotating, fine water mist technology, which is applied in fire rescue and other directions, can solve the problems of small spraying area, the nozzle cannot be automatically rotated at multiple angles, and the effect needs to be further improved, so as to improve the effect of fire extinguishing and spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

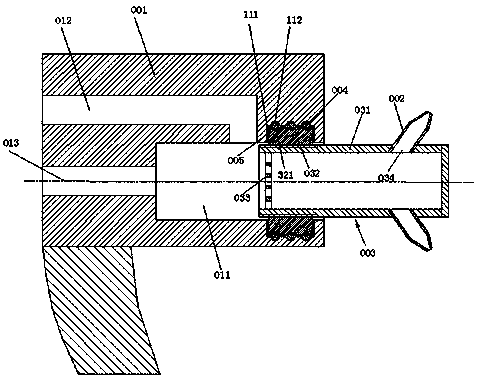

[0010] A rotatable high-pressure closed-type water mist spray gun, including a gun body 001, the gun body 001 includes a gas-liquid mixing chamber 011, a high-pressure gas pipe 012 connected to the gas-liquid mixing chamber 011, a liquid delivery pipe 013, and a gas-liquid mixing chamber 011. The nozzle 002 at the end of the mixing chamber 011, the connection between the nozzle 002 and the end of the gas mixing chamber 011 is provided with a rotatable connection device 003, the rotatable connection device 003 includes a cylinder 031, a rotating ring 032 screwed to one end of the cylinder 031, The rotating impeller 033 arranged in the cylinder 031, the outer wall of the impeller 033 is fixedly connected to the inner wall of the cylinder 031, the other end of the cylinder 031 is sealed, and two inclined connection holes 034 are opened on the side wall of the cylinder 031 near the sealing end. The connecting hole 034 is in sealing connection with the nozzle 002, the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com