Prefabricated type steel ladder

A prefabricated, steel ladder technology, applied in the direction of house structure support, house structure support, scaffolding accessories, etc., can solve the problems of inconvenient disassembly, time-consuming, heavy steel ladder, etc., to increase the anti-tilt stability, reduce The effect of the choke area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

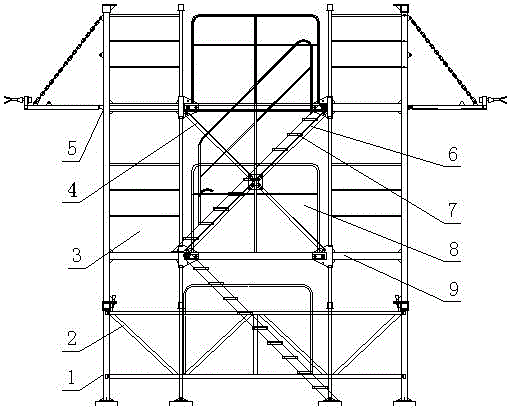

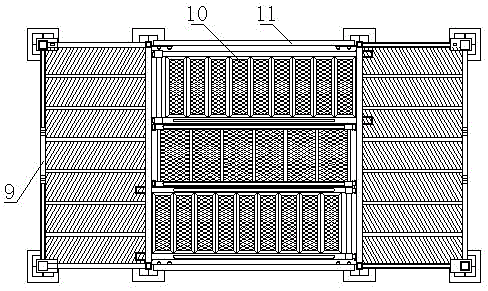

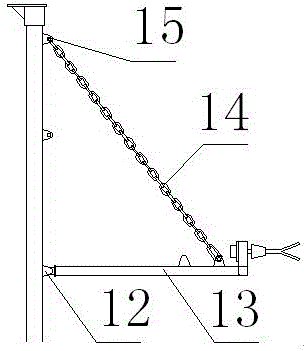

[0019] like Figure 1-2 As shown, an assembled steel ladder includes a steel ladder body 1, the bottom of which is a bottom bracket 2, the top of the bottom bracket 2 is connected with a single structural unit 3, and the outside of the single structural unit 3 is connected with a The door that opens to the inside and outside, the single structure unit 3 is connected with the main structure unit 8, and the outside of the main mechanism unit 8 is connected with a ladder 6, and the ladder 6 is provided with evenly arranged pedals 7, and the ladder 6 on the adjacent floor A horizontally arranged operating platform 9 is provided at the intersection of the two, and a horizontal connecting rod 11 is arranged on the operating platform 9, and an operating panel 10 that can be opened downward is arranged in the middle of the adjacent horizontal connecting rod 11. The opened operating panel 10 is For the stairs used by construction personnel to go up or down, the end of the operating pan...

Embodiment 2

[0021] like Figure 1-3 As shown, a prefabricated steel ladder includes a steel ladder body 1, and the lower part of the steel ladder body 1 is a bottom support 2, which firmly connects the structure of the steel ladder body 1 with the foundation, transfers the upper load to the foundation, and the bottom support 2 The upper part of the structure is connected with a single structural unit 3, which is the basic unit. Each standard segment is composed of two single-section welded structures connected by intermediate connecting rods, which mainly play the role of forming the main body of the structure. After hanging standard ladders and horizontal jumps on it, personnel can pass freely up and down, and arrive at the construction work place. The outside of the single structural unit 3 is connected with a door that can be opened to the inside and the outside, and each section of the single structural unit 3 is provided with 2 doors, and the door is connected with the operation pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com