Tensile torsion fatigue comprehensive testing machine for rubber materials

A comprehensive test and rubber material technology, which is applied in the field of rubber material fatigue performance detection devices, can solve the problems of inability to provide test environment and test methods, low reliability, large error of performance parameters, etc., and achieve simple structure, convenient use, and measurement The effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

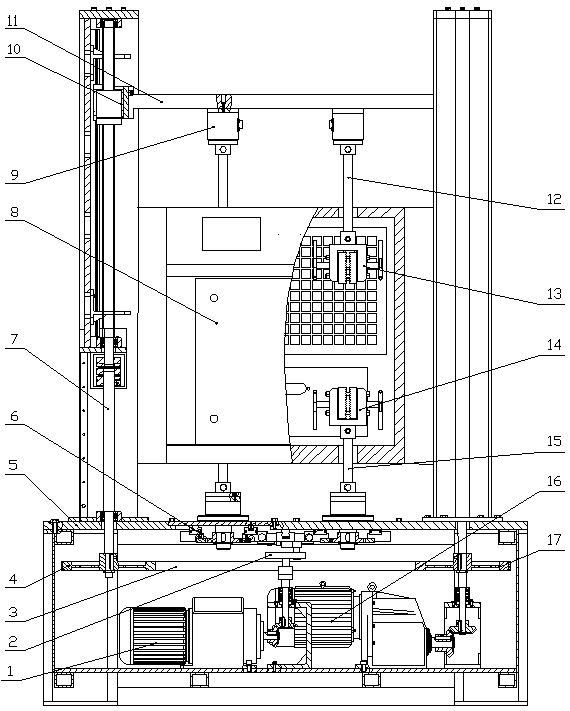

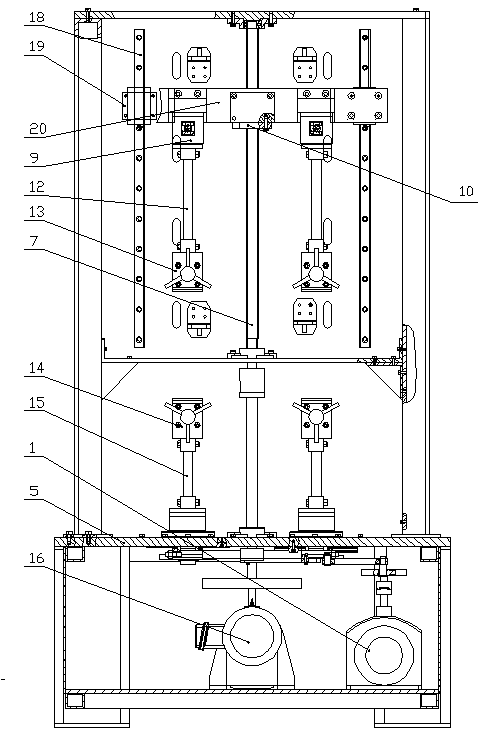

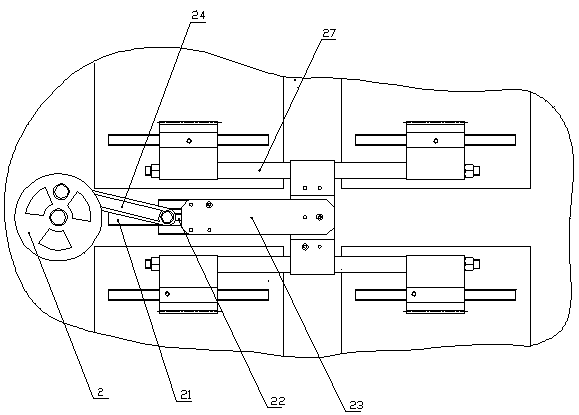

[0017] Such as Figure 1-5 The tensile and torsion fatigue testing machine for rubber materials shown is provided with a mounting bracket 5, a stretching motor 16 and a torsion motor 1 are provided in the lower part of the mounting bracket 5, and at least two parallel lifting guide rails are vertically provided on the mounting frame 5 18. Each lifting guide rail 18 is provided with a lifting slide seat 19, and the two lifting slide seats 19 of each lifting guide rail 18 are provided with an active beam 20. The active beam 20 is provided with an upper chuck, and the mounting bracket 5 is provided with There is a stretching screw, the stretching screw is a ball screw, the screw 7 of the stretching screw is connected to the stretching motor, the nut 10 of the stretching screw is connected to the active beam 20, the stretching motor 16 works, and drives the stretching The screw rod 7 of the lead screw rotates to drive the nut 10 and the active crossbeam 20 to move up and down; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com