Pressure sensor high-temperature dynamic calibration device

A pressure sensor and dynamic calibration technology, which is applied to measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as inaccurate pressure information, inability to effectively trace the source of pressure calibration devices, and inability to reflect the temperature response characteristics of pressure sensors. difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

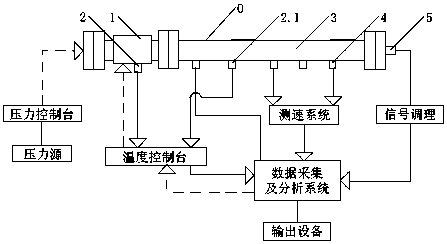

[0013] according to figure 1 It means that the pressure source sends the pressure signal to the shock tube 0 through the pressure console, and the first temperature sensor 2 is installed on the high pressure chamber of the shock tube, and the first temperature sensor transmits the temperature signal to the temperature console, and the shock tube A high-pressure chamber heating device 1 is installed on the top, a second temperature sensor 2.1 is installed in the low-pressure chamber of the shock tube, and a low-pressure chamber heating device 3 is installed. The second temperature sensor transmits the temperature signal to the temperature console, and the temperature console sends the second The temperature signal is transmitted to the data acquisition and analysis system. The second temperature sensor and the calibrated pressure sensor 4 input the temperature and pressure signals to the data acquisition and analysis system through the speed measurement system. The tail end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com