Multilayer track laying and transporting bracket

A technology of rails and columns, applied in the field of multi-layer rail laying support, can solve the problems of inconvenient up and down, small transportation volume, slow speed, etc., and achieve the effect of convenient layered loading and unloading and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

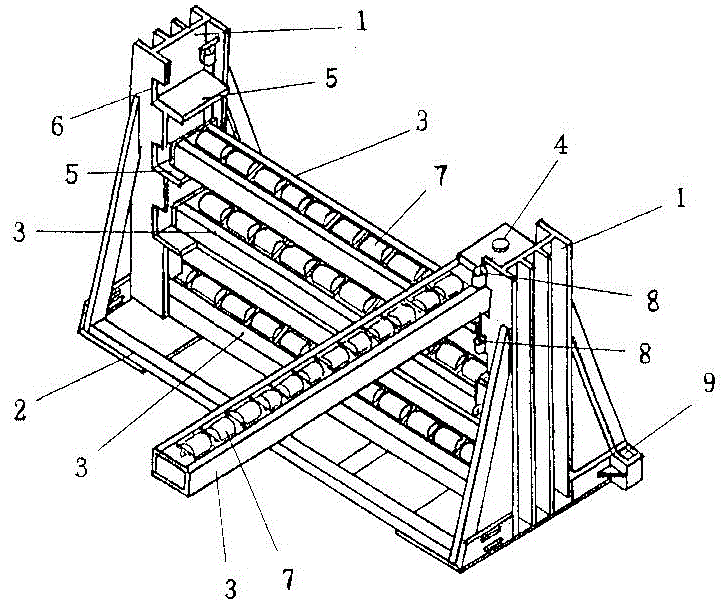

[0012] figure 1 As shown: the bracket used for laying rails is a base 2 that can be fixed on the flat bottom plate of the train, and a square steel-shaped column 1 is connected to each side of the base 2. The column 1 on one side is spaced up and down through pivot pins 4. Several The swingable crossbeam 3 for placing rails, the column 1 on the other side is provided with several grids 5 corresponding to the swingable crossbeams 3, and a plurality of rollers 7 for rolling the rails are evenly distributed on several swingable crossbeams 3. The uprights 1 on both sides are provided with positioning pins 8 for fixing the beams to be closed or unfolded. An opening 6 through which the swingable beam 3 can be adjusted is provided on the side of the column 1 provided with several grid plates 5 . Both sides of the base 2 are provided with square fixing holes 9 that are connected and fixed to the flat bottom plate of the train.

[0013] During installation and use, a plurality of bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com