A self-fluidizing high-power continuous dry distillation device and process for producing biomass gas

A dry distillation and gas technology, which is used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of short biomass residence time, long process, and the phenomenon of dry distillation chamber, and achieve stable continuous production and increase residence time. time, the effect of shortening the dry distillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

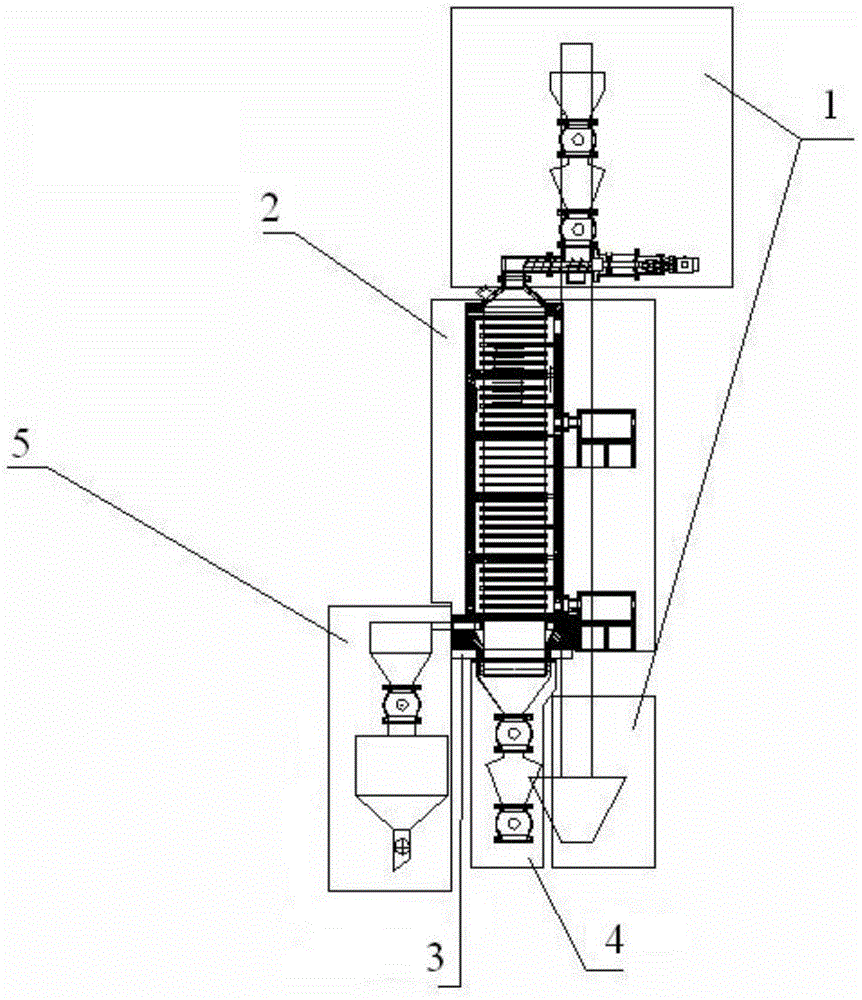

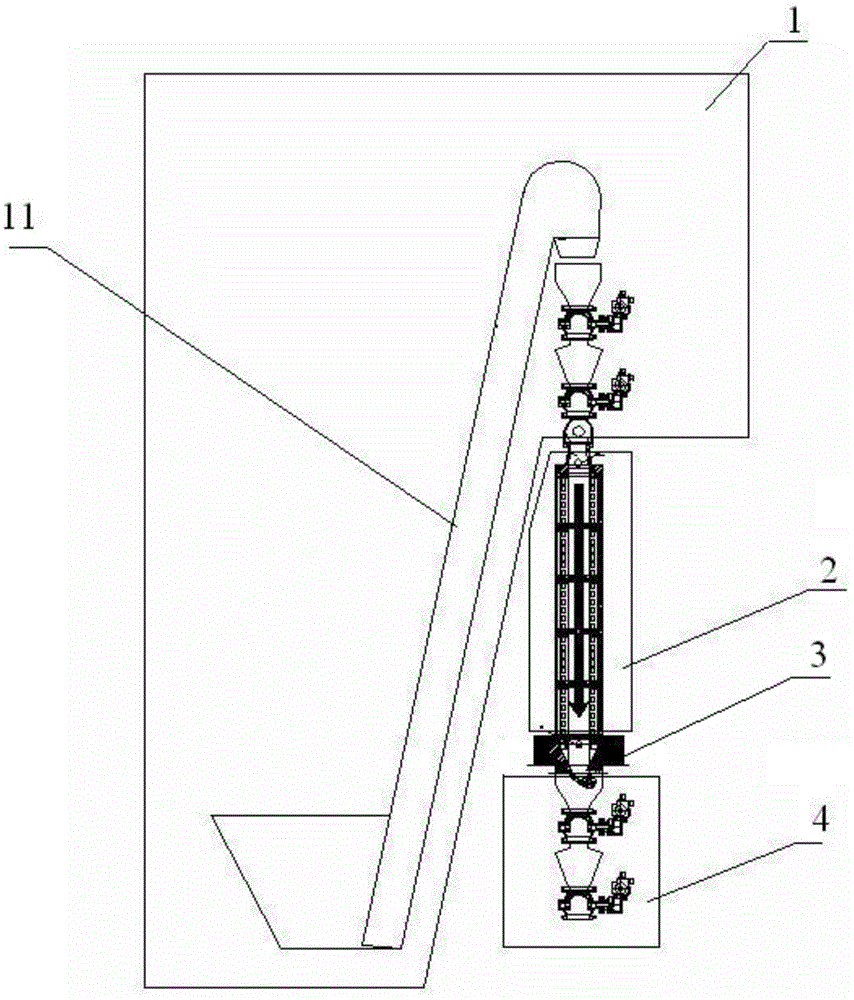

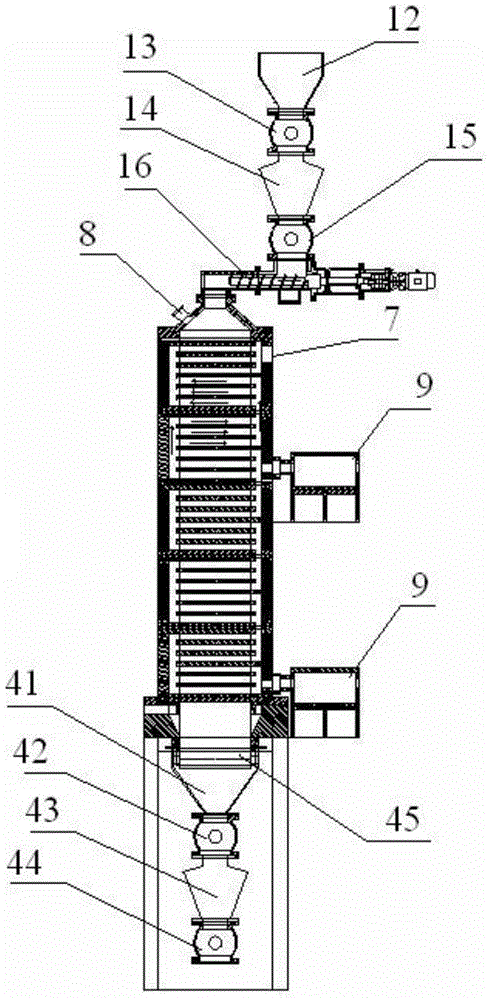

[0046] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown:

[0047] The device for producing biomass gas by self-fluidizing high-power continuous dry distillation according to the present invention is composed of a feeding device 1, a dry distillation cracking device 2, a gas exporting device 3, an interest coke carbon removal device 4 and a gas purification device 5, wherein the feed The feeding device 1 is arranged on the top of the dry distillation cracking device 2, the discharge port of the feeding device 1 communicates with the feed port of the dry distillation cracking device 2, the gas exporting device 3 and the coke decarbonization device 4 are arranged at the bottom of the dry distillation cracking device 1 and It communicates with the retort chamber of the retort cracking device 1 , and the gas purification device 5 communicates with the gas outlet device 3 .

[0048] The carbonization cracking device 2 is composed of several rows, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com