A mesh blade cloth, paraglider and windmill

A technology of flying umbrellas and blades, applied in the field of layered products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

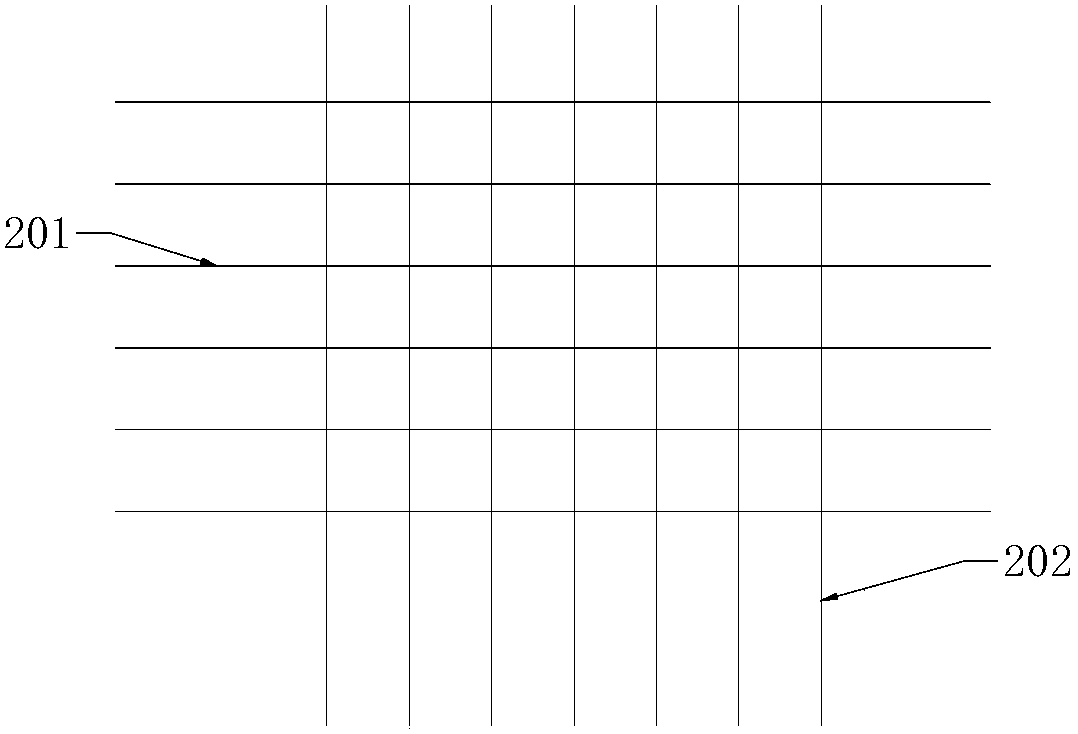

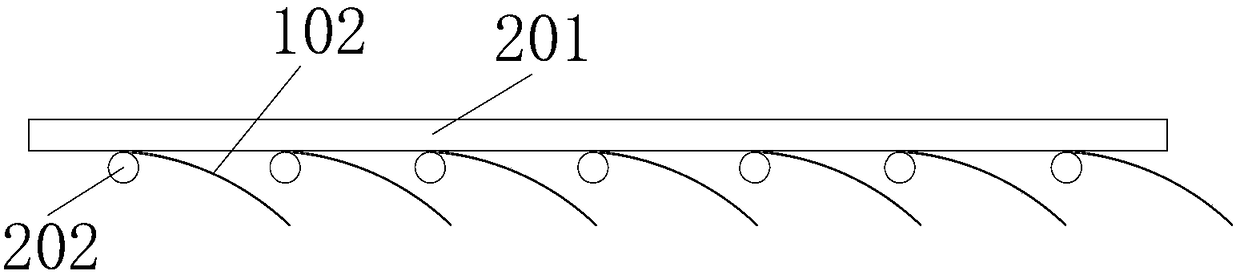

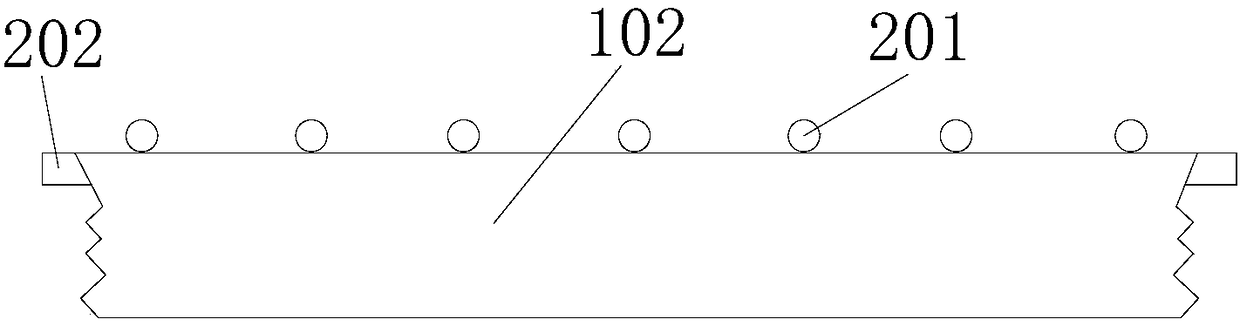

[0060] Embodiment 1, with reference to Figure 1 to Figure 5 .

[0061] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the blade 102 cloth provided by the present invention includes an upper layer wire rope 201 and a lower layer wire rope 202, the lower layer wire rope 202 includes a plurality of first wire ropes arranged side by side, the upper layer wire rope 201 includes a plurality of second wire ropes, and a plurality of first wire ropes. Two wire ropes are laid crosswise on the upper side of multiple first wire ropes; one end of each blade 102 is glued between the first wire rope and the second wire rope, and the other end is a movable end and is located below the first wire rope.

[0062] During the specific production, the lower layer wire rope 202 is first laid, and then the plurality of blades 102 are glued to the upper side of the first wire rope one by one, and the blade 102 is parallel to the plane where the grid blade cloth is l...

Embodiment 2

[0070] Example 2, such as Figure 6 to Figure 13 .

[0071] Such as Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, the paraglider provided by this embodiment includes a support frame 101, the support frame 101 is provided with a parachute surface and a support base, the parachute surface is located above the support base, and the support base is used to provide a standing position for the pilot;

[0072] The flying umbrella surface comprises an umbrella surface frame and the mesh blade cloth according to any one of claims 1-4, and the mesh blade cloth is arranged on the umbrella surface frame.

[0073] The support frame 101 is used to install the paraglider surface and the support seat, the paraglider surface provides the lift for the paraglider to glide, and the support seat provides a standing position for the glider. The blades 102 can swing at a certain angle relative to the canopy frame, and when the parachute is in a static state, the blades 102 are in a ...

Embodiment 3

[0083] Example 3, such as Figure 14 with Figure 15 .

[0084] The windmill provided in this embodiment, such as Figure 14 with 15 As shown, it includes a rotating shaft 203, an installation frame 204 and any one of the mesh blade cloth in claims 1-4, the installation frame 204 is provided with at least three, and one side edge of each installation frame 204 is fixed to the rotation shaft 203, Each installation frame 204 is correspondingly provided with a mesh blade cloth.

[0085] Regardless of the wind direction, there is always a grid blade cloth on one installation frame 204 in a windward closed state, and the other two grid blade cloths are in an open state, thereby forming an asymmetric resistance to make the windmill rotate, and the windmill can also be provided with multiple installation frames 204. This type of windmill is more efficient than other types of windmills and does not cost much. It is also possible to form a windmill group, which is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com