A kind of rubber grinding head for dental polishing and its preparation method and application

A grinding head and rubber technology, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems that the polishing gloss cannot meet the use requirements, reduce the service life of dentures, increase the discomfort of patients, and achieve reduction Temperature, prolong service life, increase the effect of polishing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

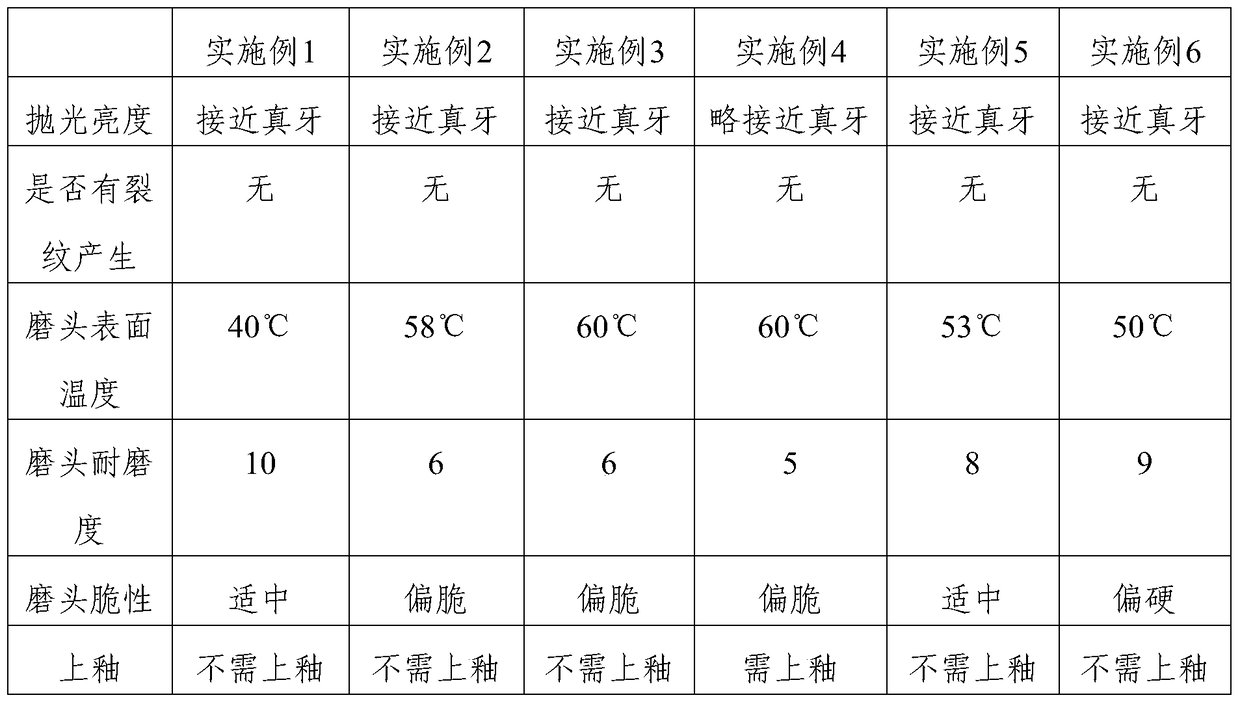

Examples

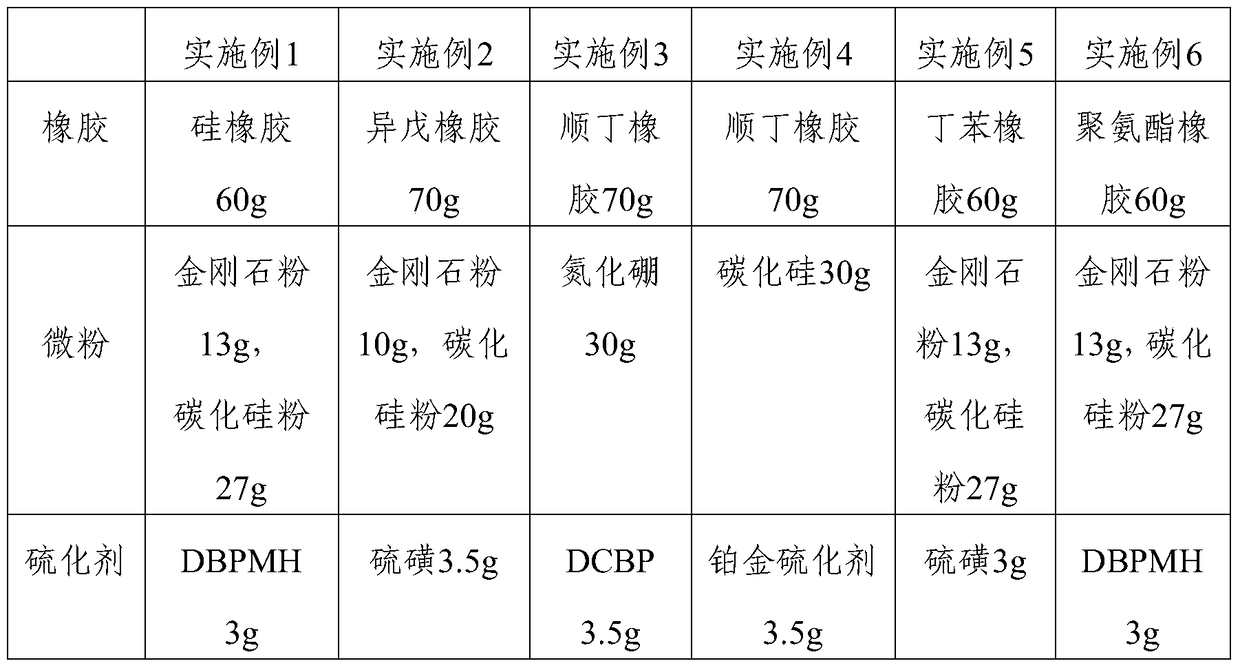

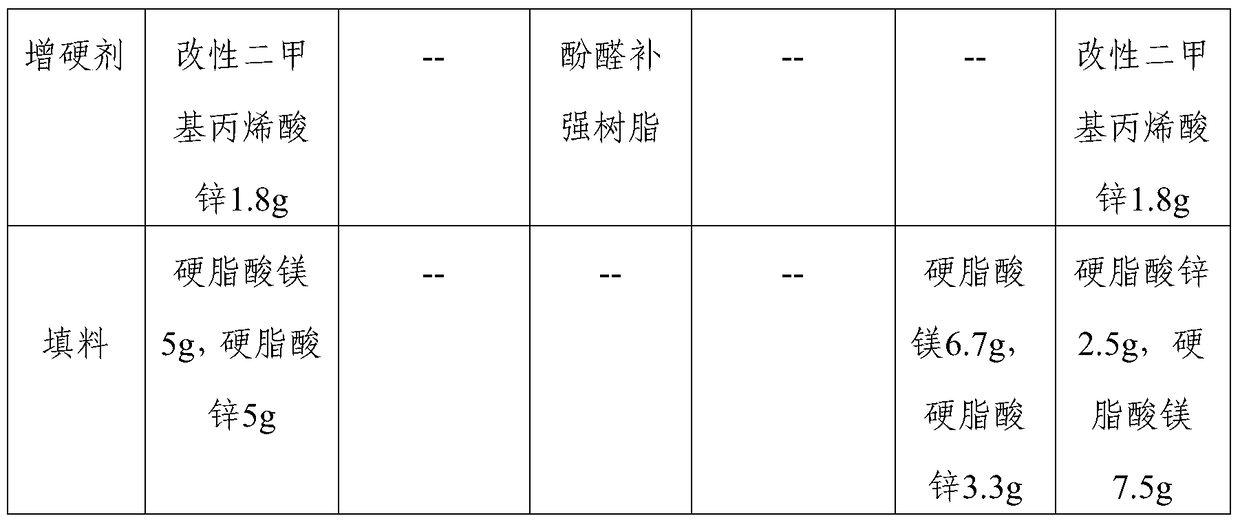

Embodiment 1~6

[0024] A kind of dental polishing rubber grinding head, described rubber grinding head is prepared by following components:

[0025]

[0026]

Embodiment 7

[0028] The present embodiment provides the preparation method of the rubber grinding head for dental polishing described in Embodiment 1, comprising the following steps:

[0029] (1) Use an open mill to mix the silicone rubber and micropowder evenly, then add zinc stearate and magnesium stearate, then add hardening agent, and finally add DBPMH, in order to ensure uniform mixing, continue mixing after adding the materials 20min.

[0030] (2) Put the mixed raw materials into the mould, and use a hot press at 100°C to press for molding.

[0031] (3) To ensure complete vulcanization, take the grinding head out of the mold and place it in an oven for secondary vulcanization at 150°C.

Embodiment 8

[0033] The present embodiment provides the preparation method of the dental polishing rubber grinding head described in embodiment 2, comprising the following steps:

[0034] (1) Mix the isoprene rubber and micropowder evenly with an open mill, and then add sulfur. In order to ensure uniform mixing, continue mixing for 20 minutes after adding the materials.

[0035] (2) Put the mixed raw materials into the mould, and use a hot press at 70°C to press and form.

[0036] (3) To ensure complete vulcanization, take the grinding head out of the mold and place it in an oven for secondary vulcanization at 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com