Connector shell and connector

A connector and housing technology, applied in the field of connector housings and connectors, can solve problems such as over-insertion of contacts, and achieve the effect of avoiding over-insertion and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

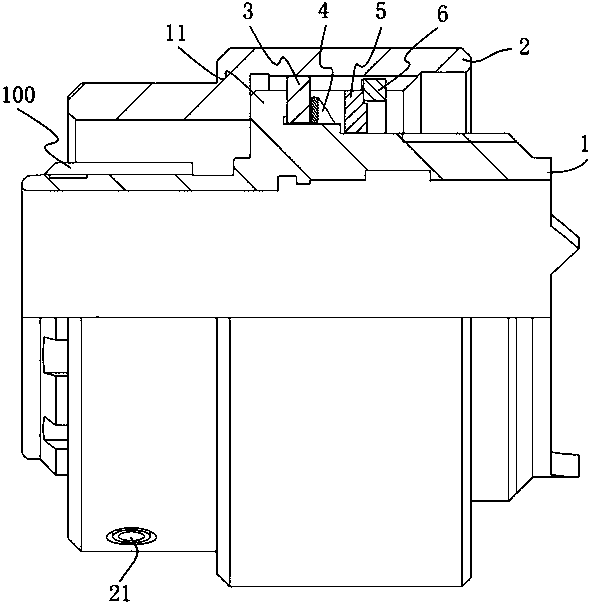

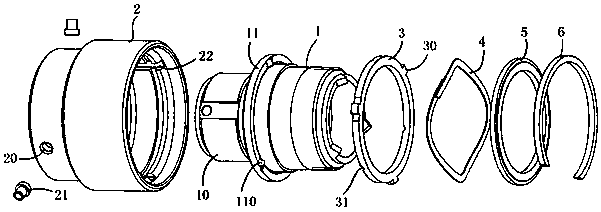

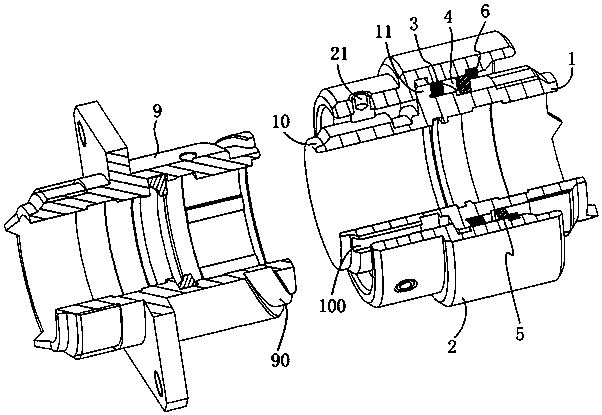

[0019] Embodiment 1 of the connector of the present invention includes a connector housing and a contact piece disposed in the housing. Among them, the structure of the connector housing is as follows Figure 1-2 As shown, it includes an outer shell 1 whose axis extends forward and backward, and a connecting nut 2 that is rotatably sleeved on the outer shell 1 and is used to lock and connect with the mating connector shell through a curved groove staple structure. The connector shell 1 The front end is the plug end 10. In this embodiment, the front end of the connecting nut 2 is provided with a staple installation hole 20, and a staple 21 is installed in the staple installation hole 20. Correspondingly, the housing of the adapter connector is provided with a groove. Certainly, in other embodiments, curved grooves may be provided on the connecting nut, and correspondingly, the staples may be provided on the insertion end of the housing of the mating connector.

[0020] The o...

Embodiment 3

[0025] Embodiment 3 of the connector of the present invention: the difference from Embodiment 1 is that there are two axial protrusions on the stopper ring, and correspondingly, there are two axial protrusions on the locking ring. At this time, the central angle corresponding to the single curved groove on the mating connector housing is 180°.

[0026] Embodiment 4 of the connector of the present invention: the difference from Embodiment 1 is that there are six axial protrusions on the stopper ring, and correspondingly, there are six axial protrusions on the locking ring. At this time, the central angle corresponding to the single curved groove on the mating connector housing is 60°.

[0027] Embodiment 5 of the connector of the present invention: the difference from Embodiment 1 is that the rear side of the connecting nut is provided with an inturned edge, and the retaining ring is located on the front side of the inverted edge and stops with the front side of the inverted ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com