Inspection gallery

A technology of maintenance channel and maintenance platform, which is applied in the direction of switchgear and electrical components, can solve the problems of inconvenient maintenance, no good foothold, shortening the creepage distance of the upper and lower valve layers, etc., and achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

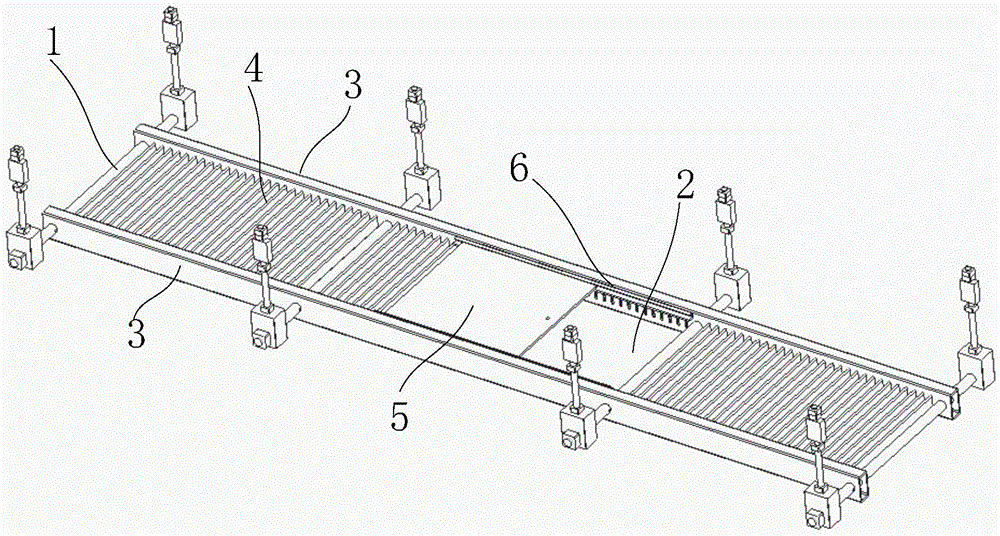

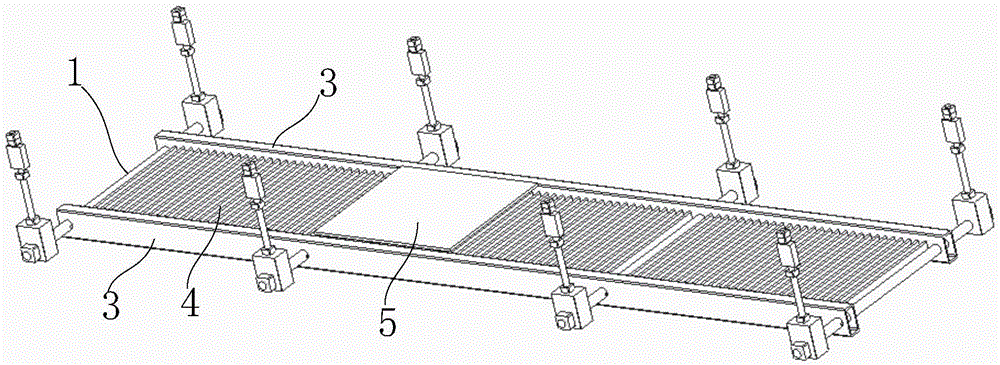

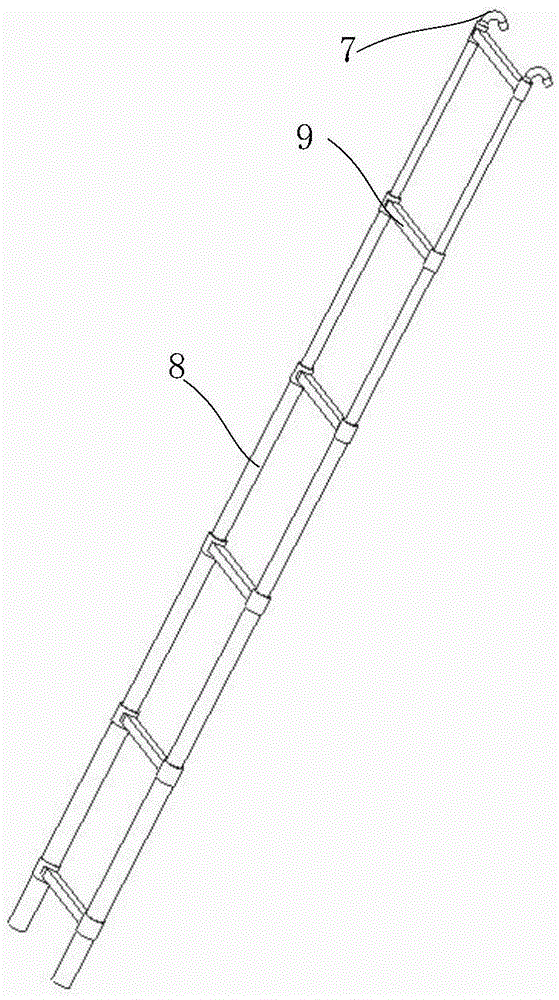

[0023] figure 1 It is a structural schematic diagram when the window of the maintenance platform of the present invention is opened, figure 2 It is a schematic diagram of the structure when the window of the maintenance platform of the present invention is covered. The maintenance platform is composed of two main beams 3, four crossbeams 1 and a plurality of crosspieces 4, and the crossbeams 1 and crosspieces 4 are installed on the two main beams 3 Evenly distributed between them, the beam 1 is used to suspend the entire maintenance platform. A window 2 is reserved on the maintenance platform, and a track 6 is also installed on each beam 3 of the maintenance platform, positioning pins 13 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com