Detect edge cracks

An edge crack, edge technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve problems such as cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

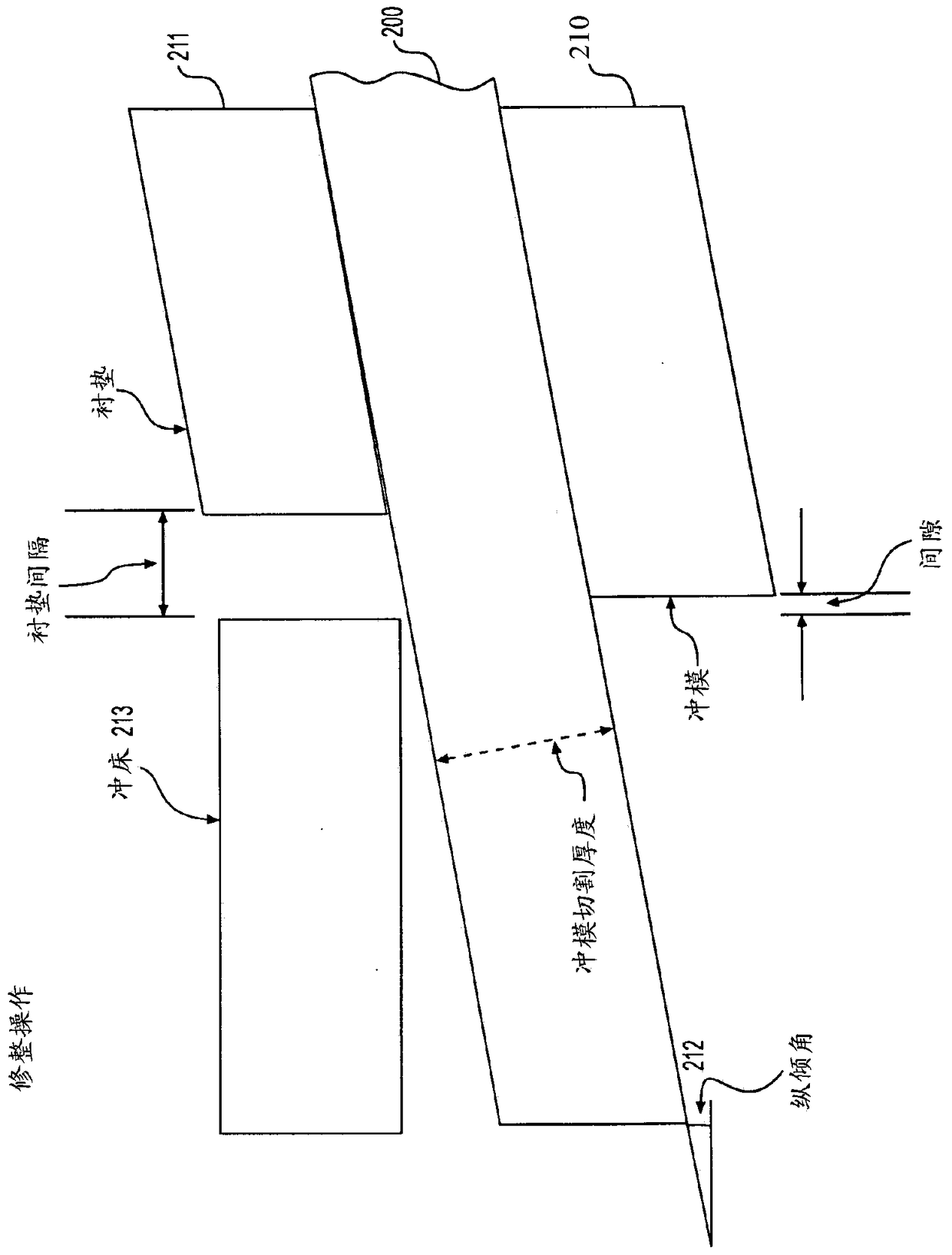

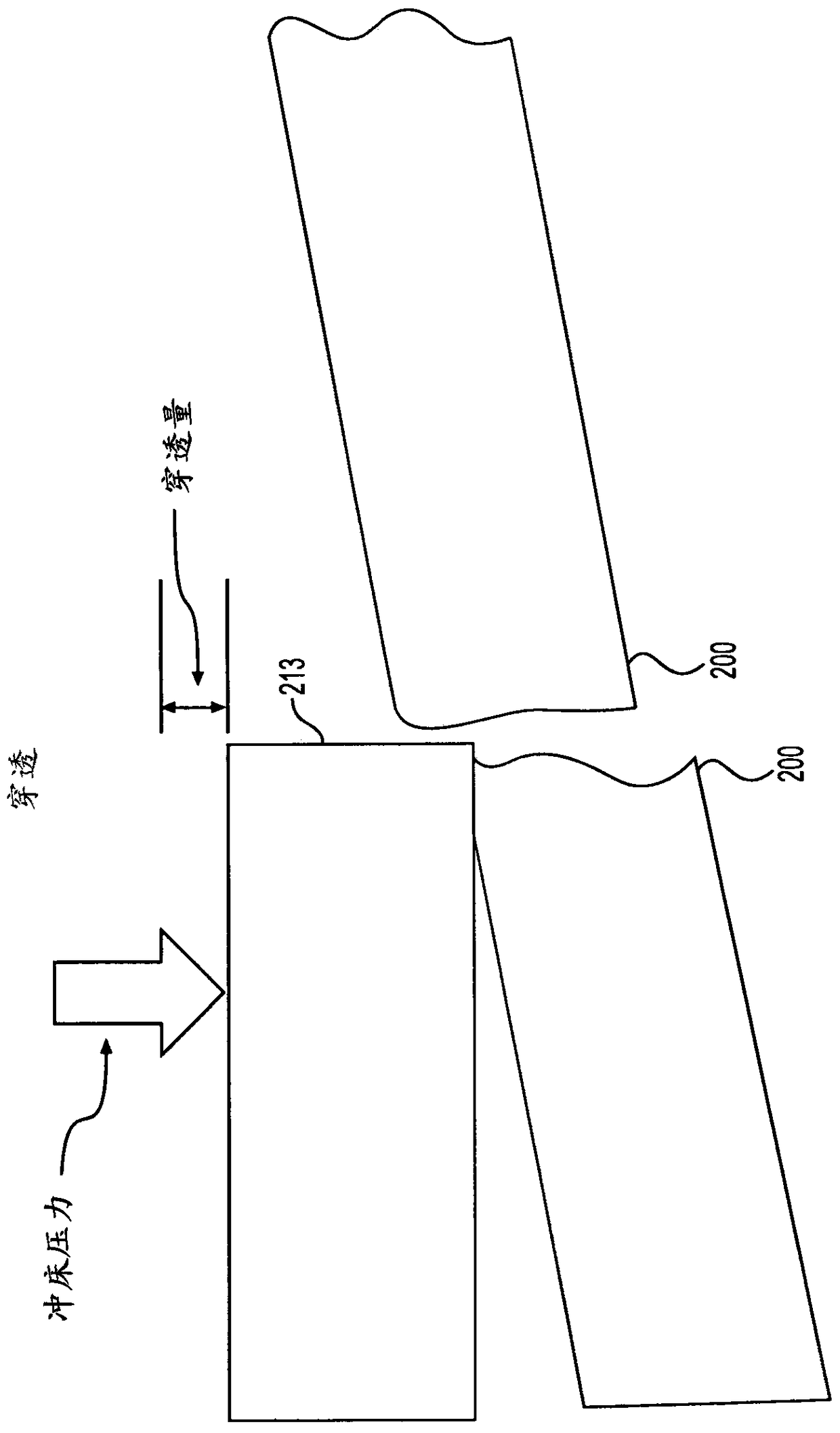

[0014] Finished products using sheet metal are manufactured by various manufacturing techniques. One such technique is to use dies to manipulate sheet metal to result in different shapes and sizes. Sheet metal dies allow sheet metal to apply pressure on sheet metal to cut, bend, stretch and manipulate sheet metal.

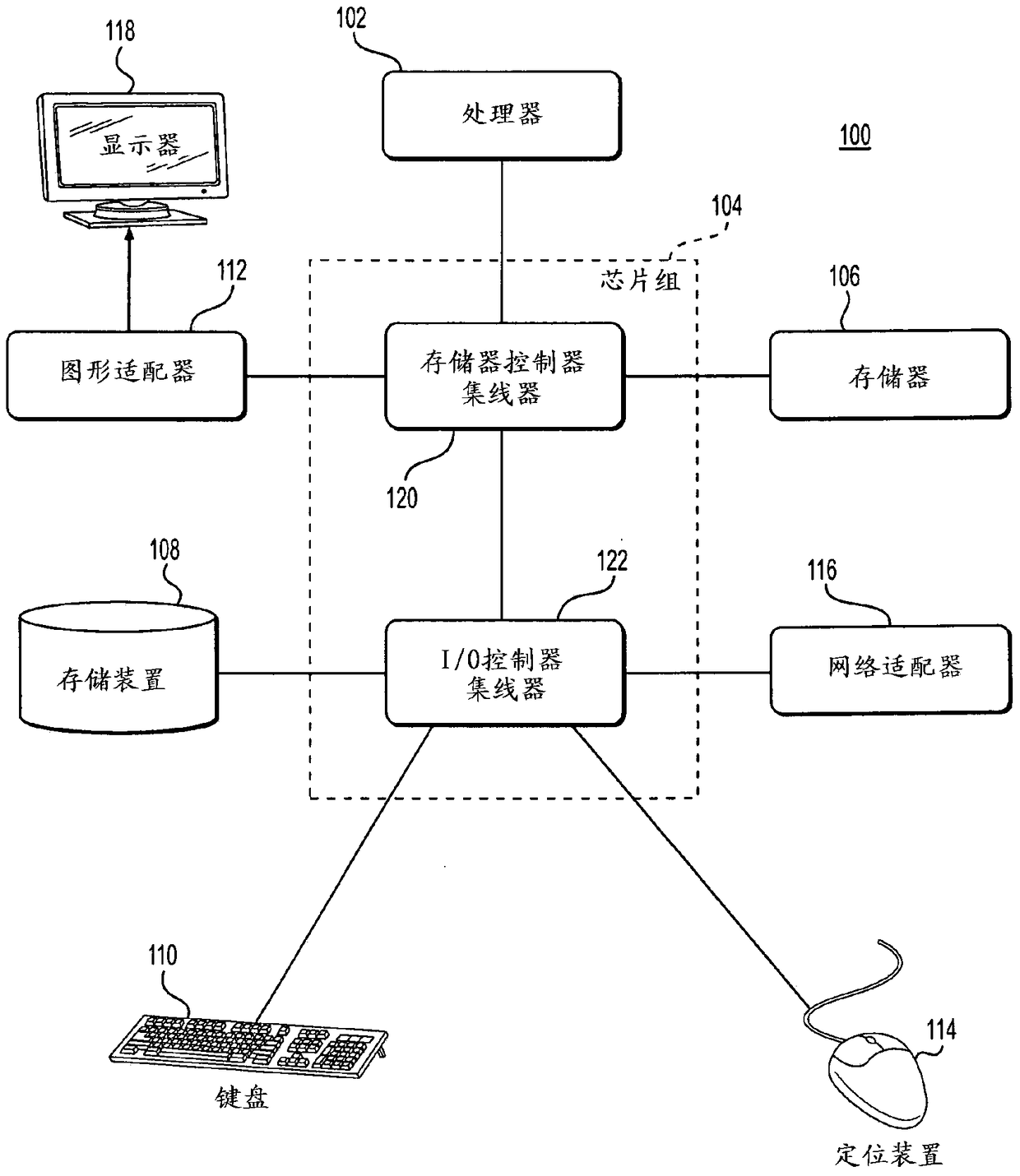

[0015] CAE programs can be used to simulate aspects of a finished product before it is produced. Therefore, a designer of a finished product can simulate the finished product via a CAE program. The finished product, as well as the materials used to manufacture the finished product, such as sheet metal, may be represented via mathematical and numerical parameters. For example, dimensions, composites, and densities can be attributed to the various materials used to manufacture the finished product.

[0016] Therefore, by using a CAE program, various situations can be analyzed predictively through the finished product. For example, if the finished product is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com