a thermostatic faucet

A thermostatic faucet and a pair of technology, applied in the field of thermostatic faucets, can solve the problems of limited use and inability to meet the preferences of different users, and achieve the effects of improving the sealing effect, eliminating water leakage, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

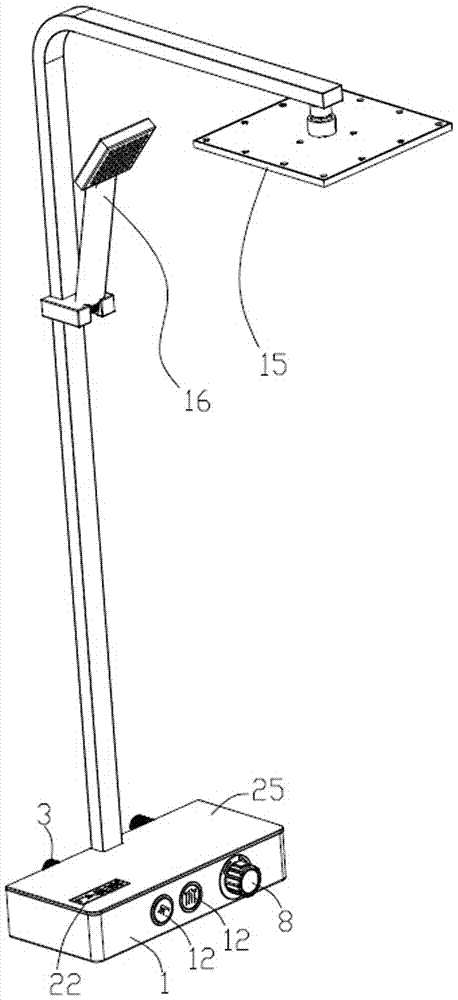

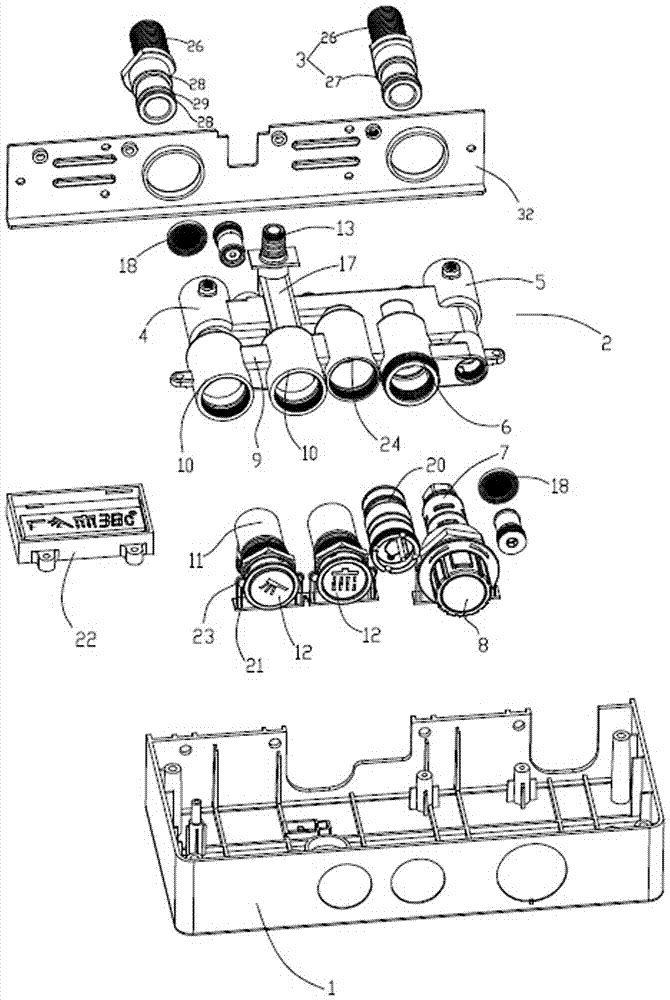

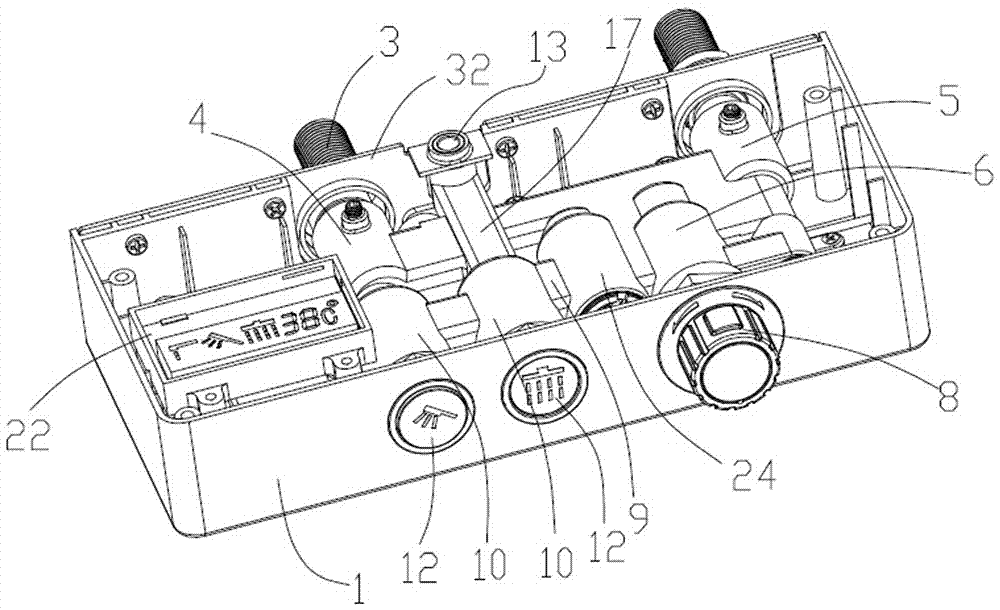

[0024] Such as Figure 1-5 As shown, a thermostatic faucet provided by the present invention includes a casing 1, a casing 2 fixed inside the casing, and a pair of water inlet elbows 3 that pass through the rear side of the casing and communicate with the casing. The casing includes The hot water inlet pipe 4, the cold water inlet pipe 5 and the mixing pipe 6 connected with the hot water inlet pipe and the cold water inlet pipe, and a pair of water inlet bends are respectively connected with the hot water inlet pipe and the cold water inlet pipe The mixing pipe is equipped with a thermostatic valve core 7, which is connected with the temperature adjustment handwheel 8 located on the shell, and the water outlet of the mixing pipe is connected with a mixed water outlet pipe 9, and there are several holes on the mixed water outlet pipe. The connected switch tubes 10 are each provided with a water outlet port, each switch tube is fixed with a switch valve 11, and the switch valves...

Embodiment 2

[0038] Such as Figure 4 , 6 , 7, the difference between this embodiment and embodiment 1 is that there are three switch tubes in this embodiment, that is, there are three water outlets and switch buttons, and a side water outlet is added on the basis of embodiment 1. 33. The side water outlet interface is connected with a bubbler 34, and the bubbler is facing the side water outlet 35 on the front side of the casing so that water can be discharged from the side water outlet.

[0039] In this embodiment, the side water outlet port is located at the end away from the mixing pipe, and the on-off valve corresponding to the side water outlet port can be opened only after the switch valves corresponding to the upper water outlet port and the lower water outlet port are opened, and the water outlet methods are more diverse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com