Method for installing heating module on basic plane

A technology of base surface and heating material, which is applied in the field of installing heating modules on the base surface, which can solve the problems of inability to heat quickly, limited laying area, and high laying conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

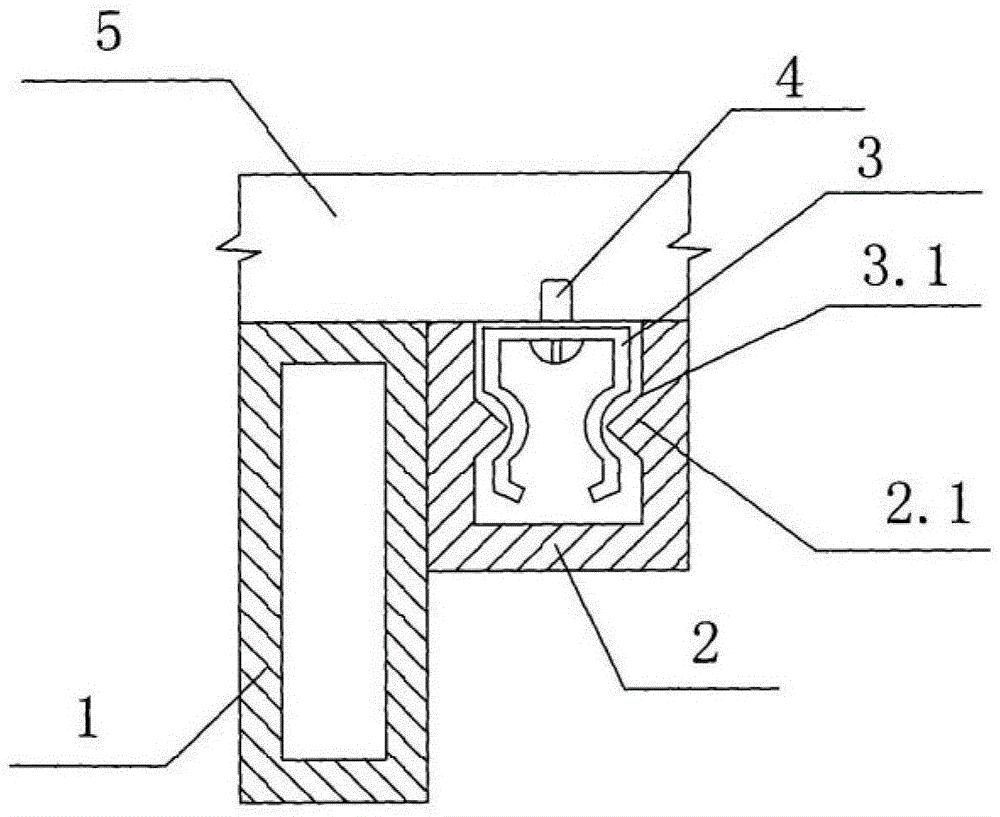

[0020] Installation example 1: The card slot 2 is set on the side of the beam 1 and is fixedly connected with the beam 1 . Protruding lines 2.1 are provided on the groove wall of the buckle slot 2 . The spring clasp 3 is arranged on the inner side of the heating module 5 , and is fixedly connected with the heating module 5 by screws 4 . A groove 3.1 matching with the raised strip 2.1 is provided on the spring clasp 3 . When installing the heating module 5, just align the spring buckle 3 with the buckle slot 2 and push it in forcefully; when disassembling the heating module 5, just use a glass suction cup to pull the heating module 5 out of the buckle slot Just go out.

Embodiment 2

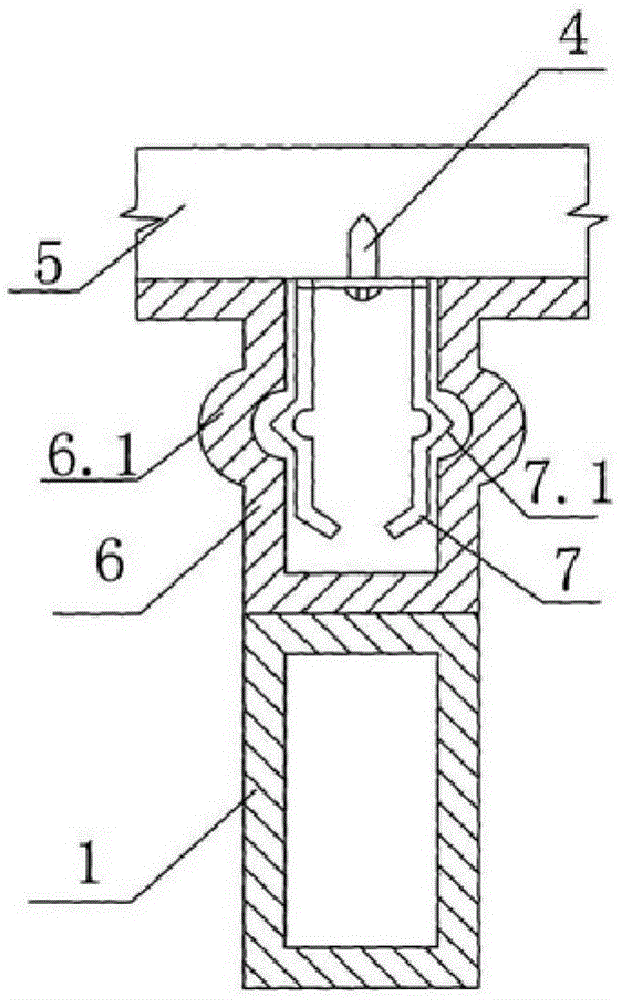

[0021] Installation example 2: the buckle slot 6 is arranged on the side of the beam 1 and is fixedly connected with the beam 1 . A groove 6.1 is provided on the groove wall of the clip groove 6 . The spring clasp 7 is arranged on the inner side of the heating module 5 , and is fixedly connected with the heating module 5 by screws 4 . A protruding strip 7.1 matched with the groove 6.1 is provided on the spring clasp 7 . When installing the heating module 5, just align the spring buckle 7 with the buckle slot 6 and forcefully push it in; similarly, when removing the heating module 5, just use a glass suction cup to pull the heating module out of the buckle slot Just pull it out.

[0022] The invention provides a method for installing the heating module on the foundation surface, which can lay the heating module on the ground or the wall, and has low requirements on the laying conditions. Heat, and low cost, suitable for home use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com