Method for installing heating module on foundation surface

A technology of base surface and heating material, which is applied in the field of installing heating modules on the base surface, which can solve the problems of high requirements for laying conditions, high cost, and limited laying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

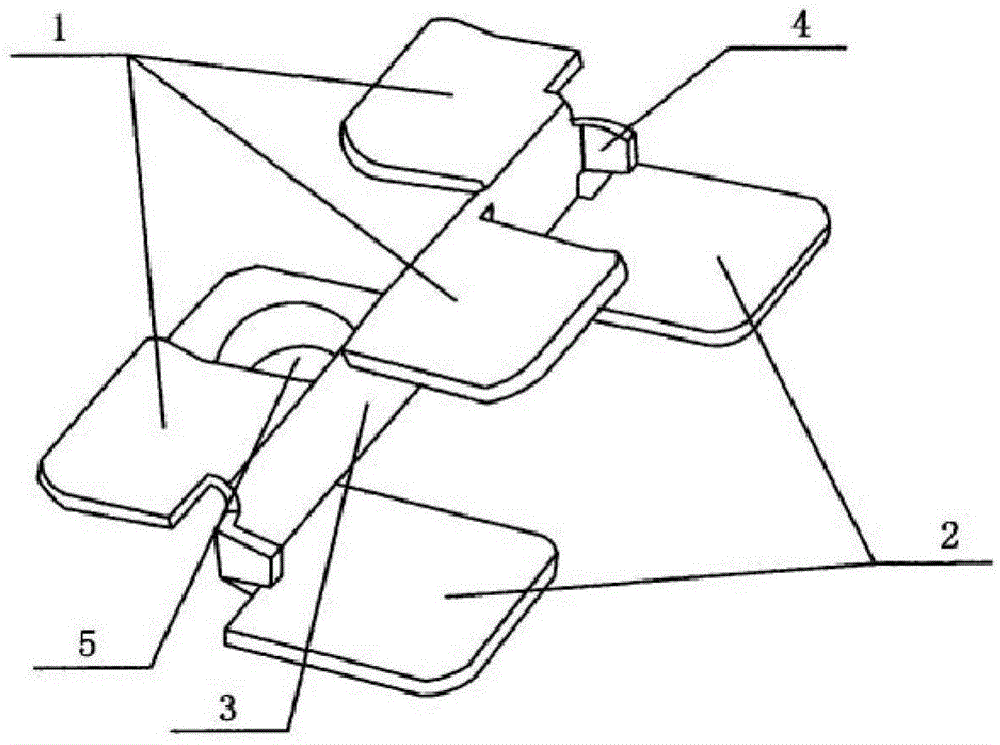

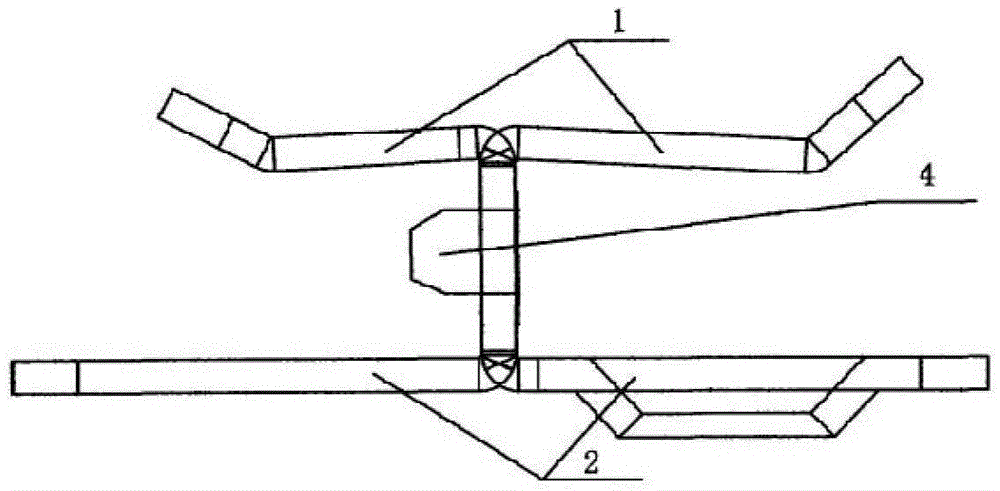

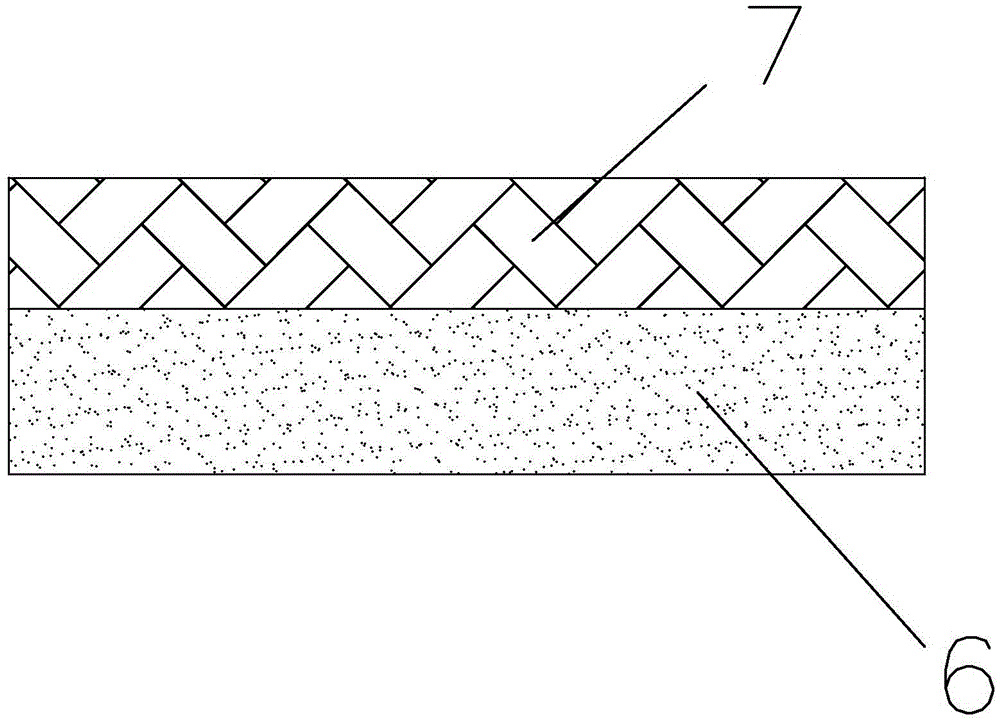

[0016] Figure 1-3 As shown, a method for installing the heating module on the base surface. In practice, the base surface is selected as the ground, the carrier of the heating module is a wooden board 6, and the planar heating material 7 is placed on the surface of the carrier.

[0017] The installation structure is composed of the upper wing 1, the lower wing 2, the horizontal plate 3, and the tongue 4; the upper wing 1 and the lower wing 2 are parallel to each other, the width of the upper wing 1 matches the width of the groove of the heating module, and the horizontal plate 3 is set Between the upper wing 1 and the lower wing 2, the upper wing 1 and the lower wing 2 are connected by a vertical horizontal plate 4, and tongues 4 are arranged at both ends of the horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com