A Feed Rate Optimization Method for NC Machining Based on Material Removal Rate

An optimization method and feed rate technology, applied in the direction of program control, computer control, general control system, etc., can solve the problem of low processing efficiency and achieve the effect of optimizing processing details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

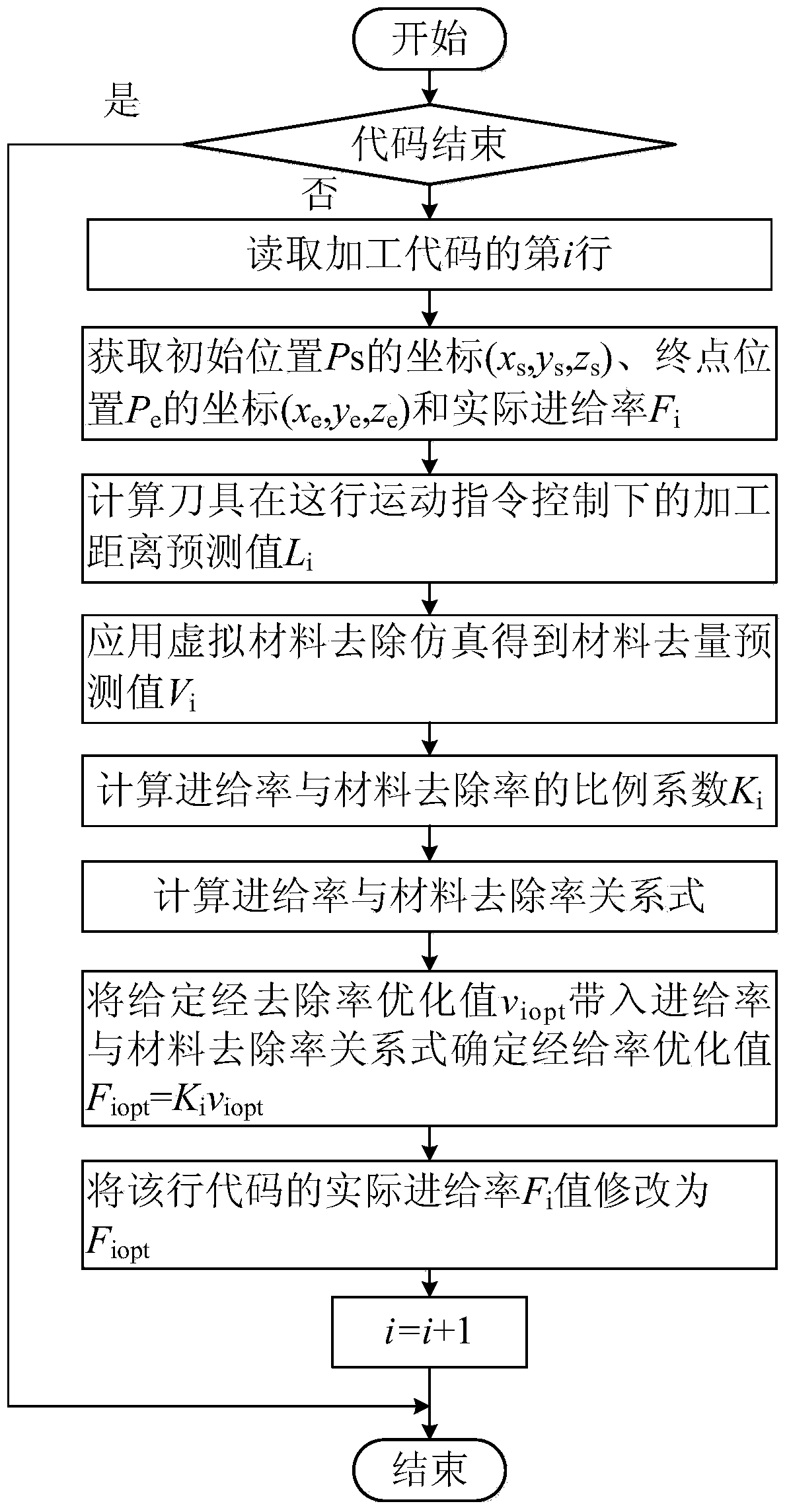

[0031] The present invention comprises the following steps (as figure 1 shown):

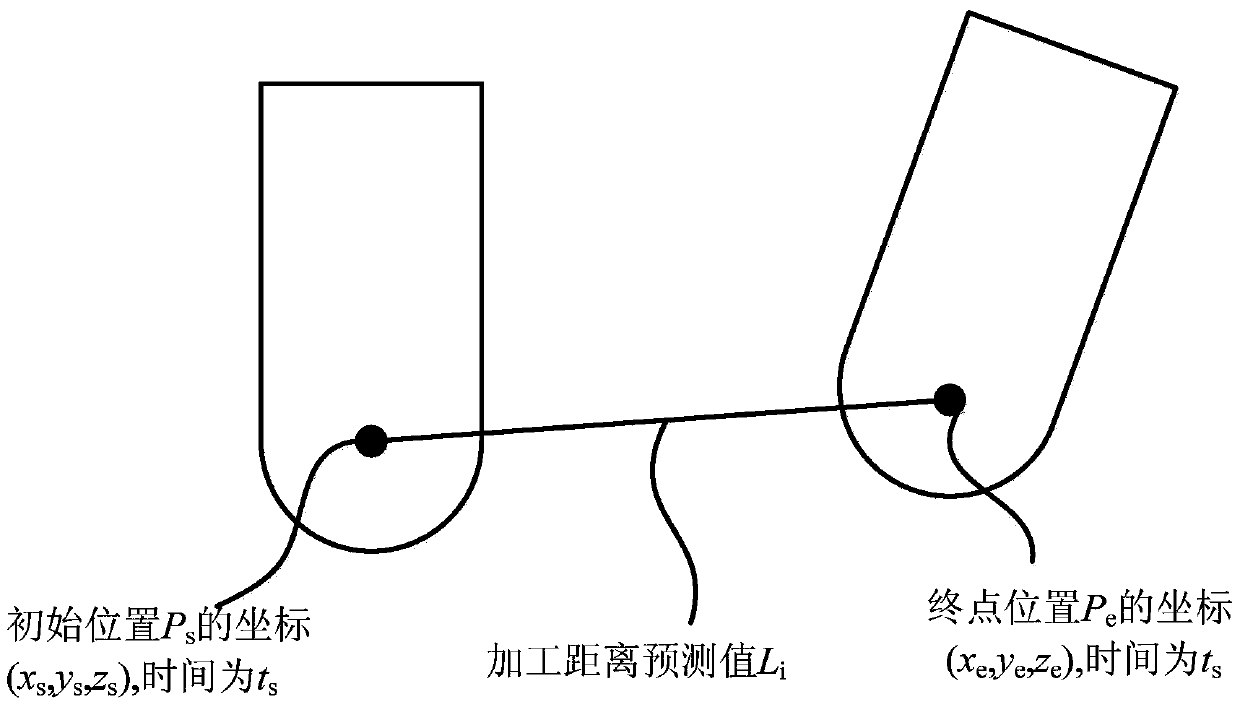

[0032] Read the data of each row of the processing code, if all the data rows have been read, the processing code optimization process ends. Otherwise, read the i-th row of data, and directly obtain the tool initial position P according to the read data before the i-th row and the i-th row of data s The coordinates (x s ,y s ,z s ), end position P e The coordinates (x e ,y e ,z e ) and the actual feed rate F of the line i .

[0033] Calculate the predicted value L of the machining distance of the tool under the control of the i line of machining instructions i . Among them, L i Calculate according to the following formula:

[0034]

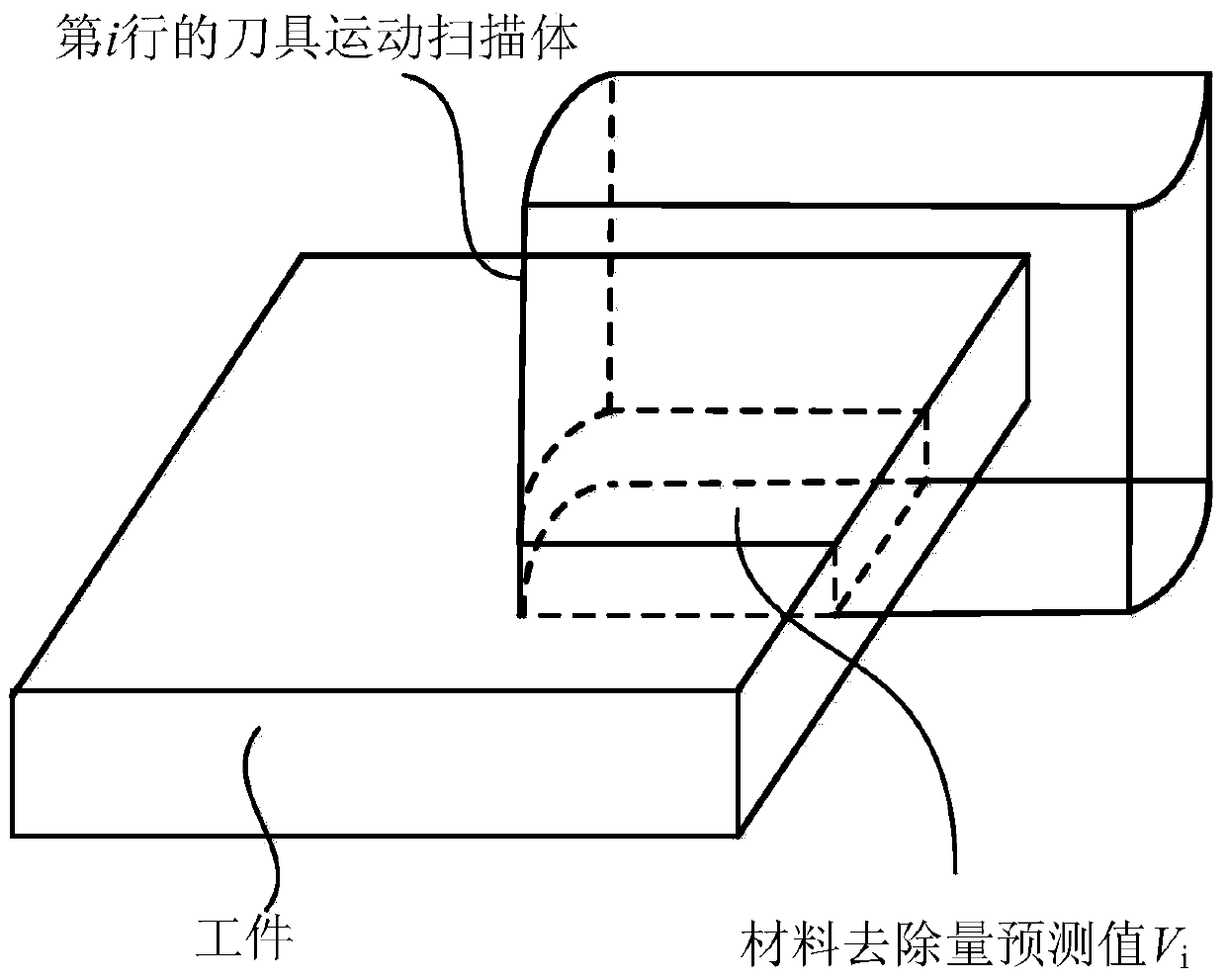

[0035] Apply the existing virtual material removal simulation, and directly obtain the volume of the cut part of the workpiece after the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com