Locking mechanism for locking automotive lamps

A technology of locking mechanism and automotive lamps, which can be applied to household appliances, other household appliances, applications, etc. It can solve problems such as difficult to ensure welding position, lower product qualification rate, inaccurate upper and lower positions, etc., and meet processing requirements and matching process requirements Not high, improve product qualification rate, and occupy less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

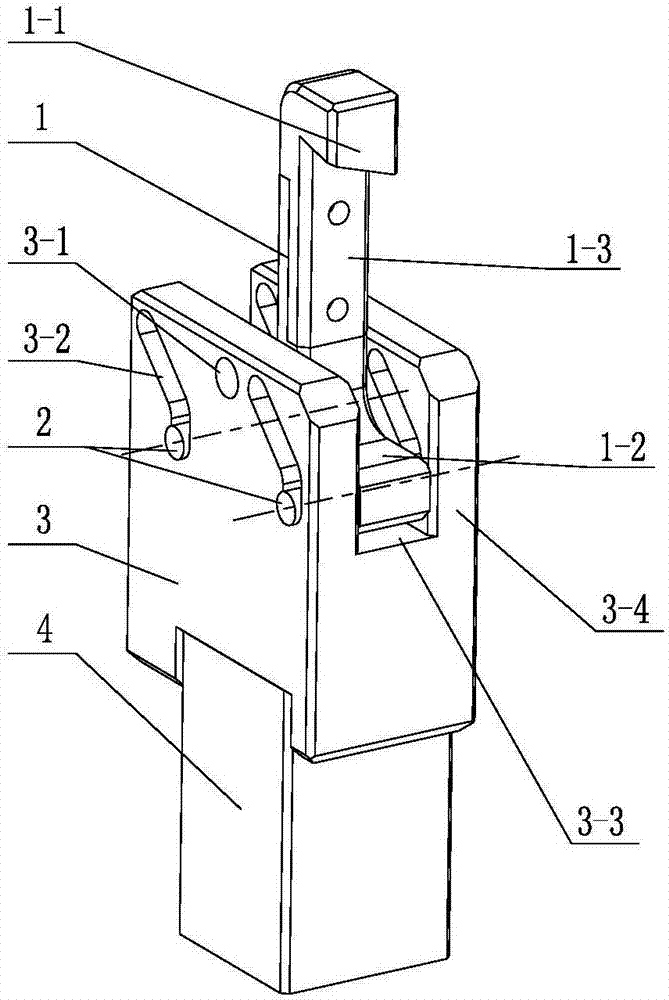

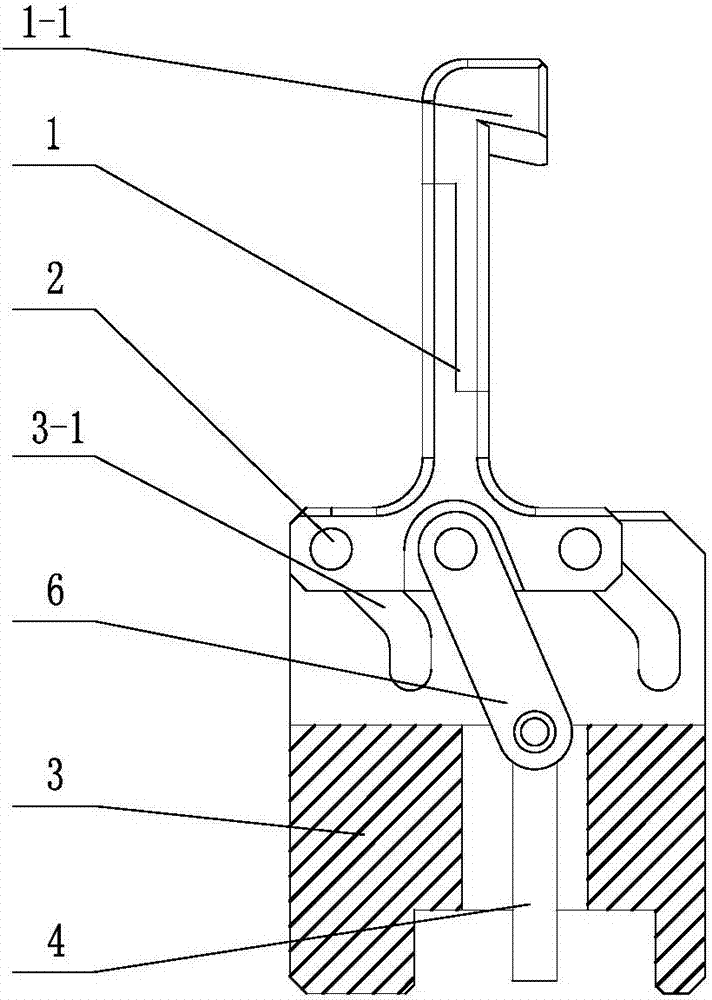

[0020] See figure 1 , 2 The locking mechanism shown for locking the automotive lamps includes a guide support 3, a connecting rod 6, a moving rod 4 for driving the connecting rod 6, and a moving rod 4 extending into the workpiece hole 7-1 and facing the top of the hole. Press down the limit clamping piece 1. See Figure 1~4 As shown, the guide support 3 of the present invention is provided with a guide chute 3-2 for placing the guide pin 2 and moving and guiding the guide pin 2, an upper cavity 3-3 for accommodating the clamping part 1 and for using The lower chamber 3-5 that the moving rod 4 passes through, and the bottom of the guide chute 3-2 is provided with a locking vertical groove, and the upper end of the connecting rod 6 passing through the lower chamber 3-5 is connected to the top of the guide support 3. The clamping part 1 of the cavity 3-3 is connected, and the lower end is connected with the moving rod 4. See figure 1 , 2 As shown, the clamping part 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com